Heat storage equipment for absorbing heat energy of molten calcium carbide by binary salt

A technology of binary salt and calcium carbide, which is applied in heat storage equipment, lighting and heating equipment, heat exchanger types, etc., can solve problems such as the inability to directly collect the heat of molten calcium carbide and the adhesion of salt blocks, so as to improve the generation efficiency and speed up The effect of heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

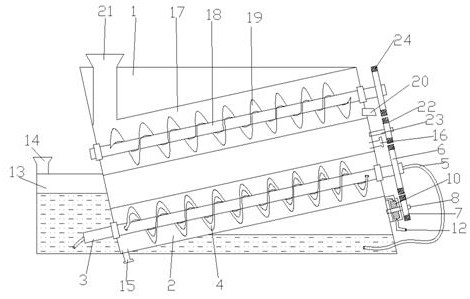

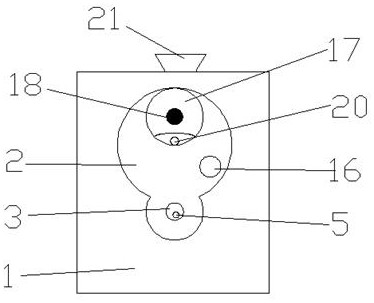

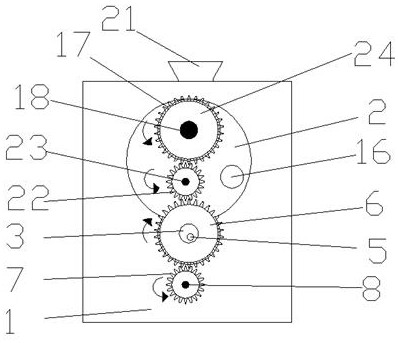

[0032] refer to Figure 1-5, a heat storage device that uses binary salts to absorb heat energy of molten calcium carbide, including a thermal insulation shell 1. The thermal insulation shell 1 is specifically a frame structure with a square end face and a parallelogram-shaped side surface. The thermal insulation shell 1 is embedded with oblique The salt storage tank 2 is a gourd-shaped special-shaped cylinder structure formed by the intersection of two upper and lower cylinders, and the radius of the lower cylinder of the salt storage tank 2 is smaller than the radius of the upper cylinder, and the lower cylinder of the salt storage tank 2 is round The cylinder is p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com