A kind of electrode and preparation method thereof

An electrode and electromagnetic technology, applied in the field of electrodes for supercapacitors and their preparation, can solve the problems of uncontrollable fibrillation direction of mixed dry powder, large amount of binder, and large material loss, so as to achieve short heating time and avoid material loss. , the effect of reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] S1, take by weighing 950g activated carbon powder, 20g acetylene black and 30g polytetrafluoroethylene powder and add in double-cone rotary vacuum mixer and mix evenly, obtain 1000g mixed dry powder;

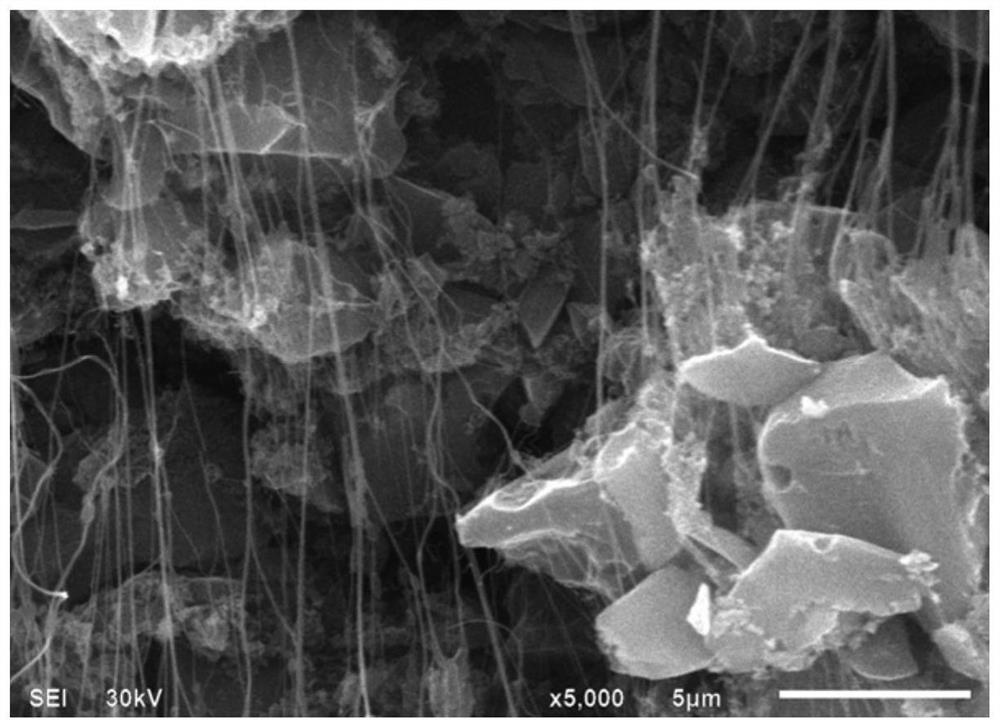

[0065] S2. Use a conduit with a length of 1m and an inner diameter of 1cm to connect the double-cone rotary vacuum mixer and the receiving barrel from top to bottom. After turning on the switch of the conduit, use a high-energy electromagnetic shock wave generator to focus and impact the free-falling mixed dry powder in the conduit. The impact energy is set. It is set at 6MPa, the impact frequency is set at 25Hz, and the impact area is set at 0.785cm 2 , until all the mixed dry powder in the double-cone rotary vacuum mixer falls freely through the conduit to the receiving barrel below, and 1000g of fibrous mixed dry powder is obtained;

[0066] S3. Using a vibrating blanking powder spreader, the fibrous mixed dry powder obtained in S2 is quantitatively dropped to the cent...

Embodiment 2

[0069] S1, take by weighing 930g activated carbon powder, 20g acetylene black and 50g polytetrafluoroethylene powder and add in double-cone rotary vacuum mixer and mix evenly, obtain 1000g mixed dry powder;

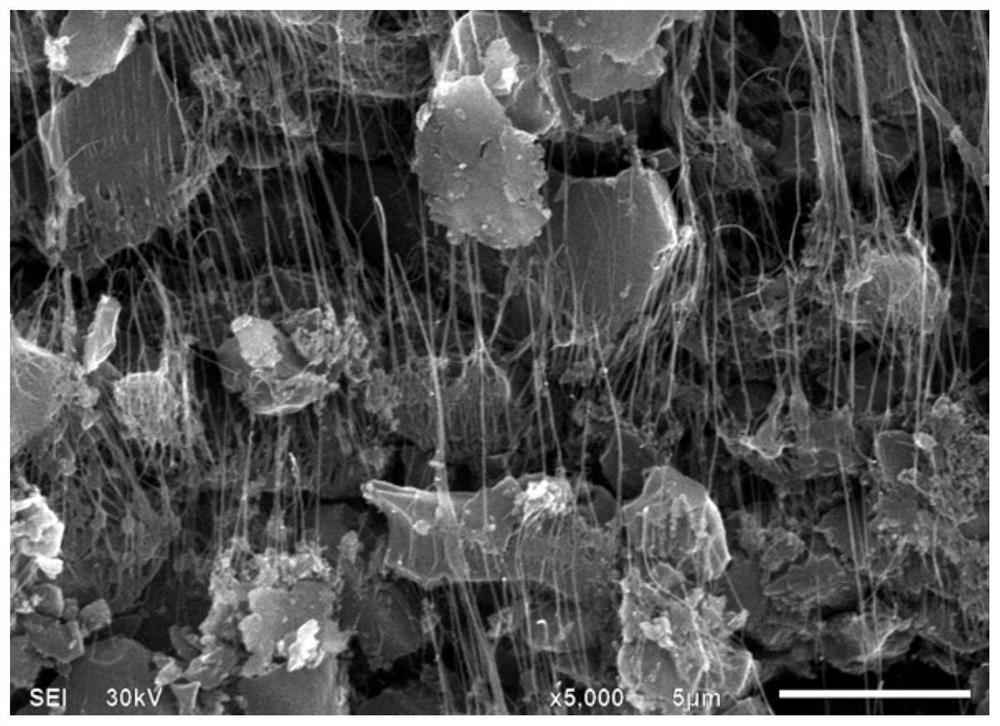

[0070] S2. Use a conduit with a length of 1m and an inner diameter of 1cm to connect the double-cone rotary vacuum mixer and the receiving barrel from top to bottom. After turning on the switch of the conduit, use a high-energy electromagnetic shock wave generator to focus and impact the free-falling mixed dry powder in the conduit. The impact energy is set. It is set at 6MPa, the impact frequency is set at 25Hz, and the impact area is set at 0.785cm 2 , until all the mixed dry powder in the double-cone rotary vacuum mixer falls freely through the conduit to the receiving barrel below, and 1000g of fibrous mixed dry powder is obtained;

[0071] S3. Using a vibrating blanking powder spreader, the fibrous mixed dry powder obtained in S2 is quantitatively dropped to the cent...

Embodiment 3

[0074] S1, take by weighing 930g activated carbon powder, 20g acetylene black and 50g polytetrafluoroethylene powder and add in double-cone rotary vacuum mixer and mix evenly, obtain 1000g mixed dry powder;

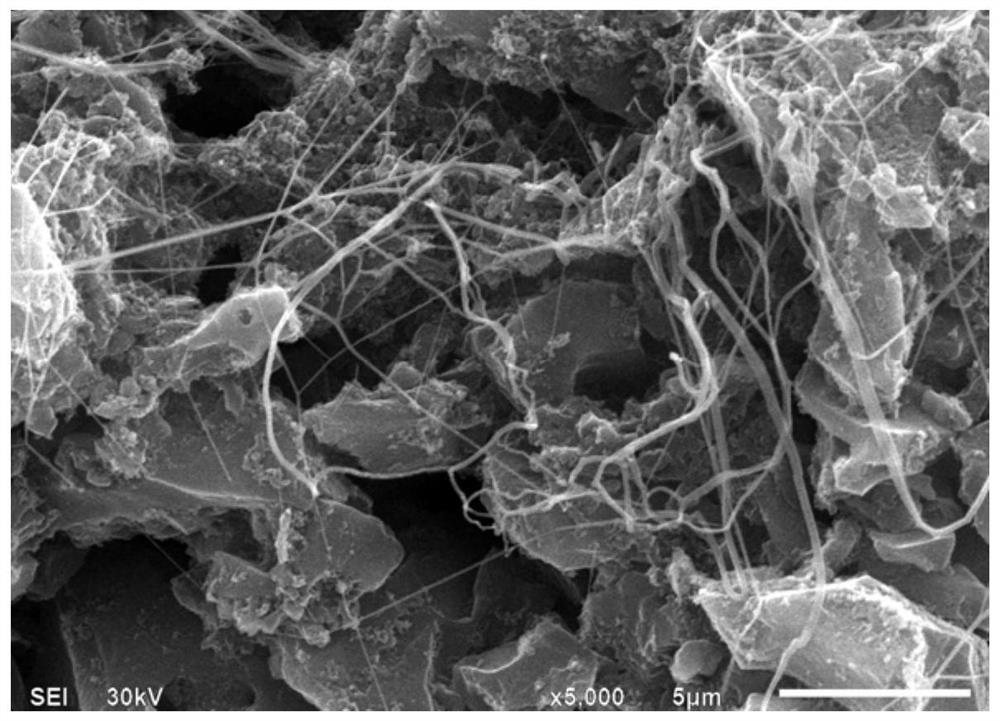

[0075] S2. Use a conduit with a length of 1m and an inner diameter of 1cm to connect the double-cone rotary vacuum mixer and the receiving barrel from top to bottom. After turning on the switch of the conduit, use a high-energy electromagnetic shock wave generator to focus and impact the free-falling mixed dry powder in the conduit. The impact energy is set. It is set at 8MPa, the impact frequency is set at 32Hz, and the impact area is set at 0.785cm 2 , until all the mixed dry powder in the double-cone rotary vacuum mixer falls freely through the conduit to the receiving barrel below, and 1000g of fibrous mixed dry powder is obtained;

[0076] S3. Using a vibrating blanking powder spreader, the fibrous mixed dry powder obtained in S2 is quantitatively dropped to the cent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com