Lithium borohydride/decaborane solid electrolyte and preparation method thereof

A solid electrolyte, lithium borohydride technology, applied in solid electrolyte, electrolyte battery manufacturing, electrolyte and other directions, can solve the problems of complex preparation process and insignificant improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

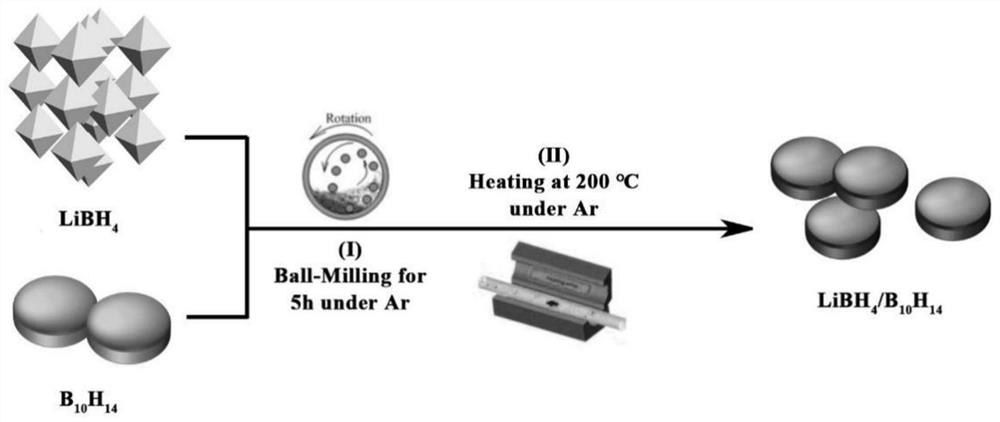

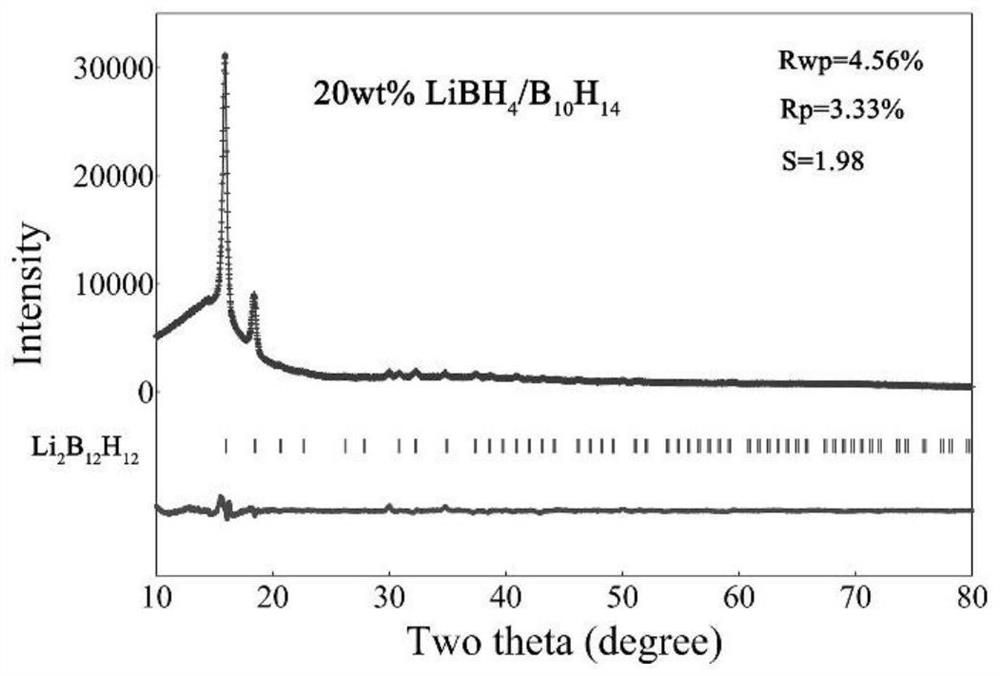

[0038] The preparation of 20wt% lithium borohydride / decaborane comprises the following steps:

[0039] At room temperature, in an argon glove box, weigh 100 mg of lithium borohydride powder and 400 m of decaborane powder, put them into agate and grind them evenly, and put the uniformly mixed product into a ball mill tank for high-energy hydrogen-filled ball milling Carry out the ball milling process: the ball-to-material ratio is 40:1, the ball milling speed is 300rpm, the ball milling time is 5h, and the hydrogen charging pressure is 4Mpa. The uniform mixture after ball milling is placed in a high temperature and high pressure sintering resistance furnace for heating and heat preservation. Process parameters: 0.2Mpa argon protection, temperature rise 5°C / min, target temperature and holding temperature 200°C, holding time 15h, cooling with the furnace. The product after cooling is 20 wt% lithium borohydride / decaborane. The schematic diagram of the solid electrolyte preparatio...

Embodiment 2

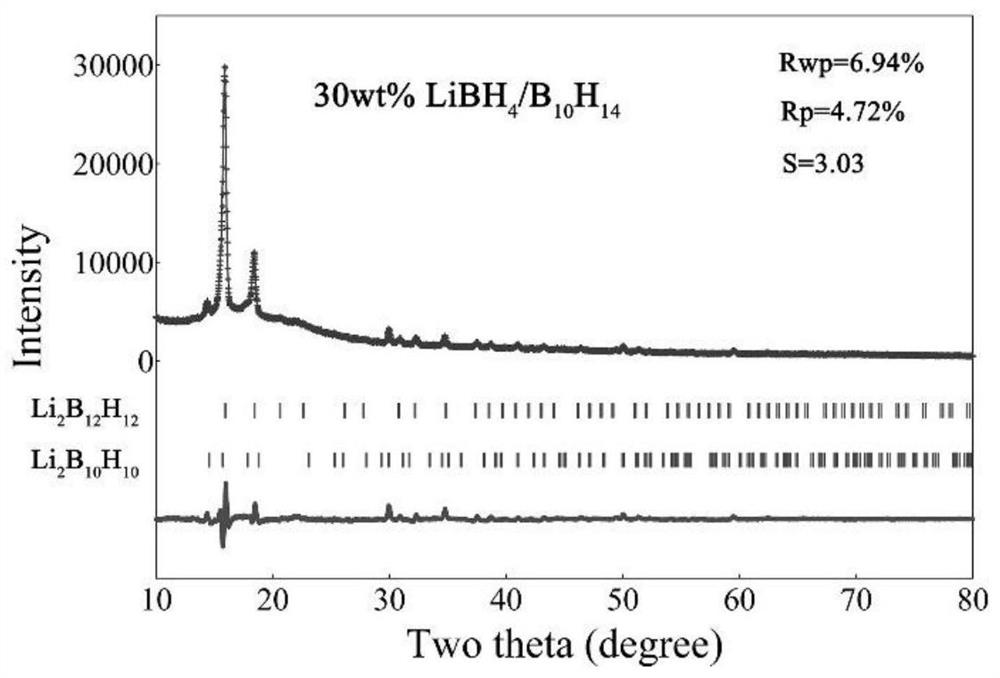

[0043] The preparation of 30wt% lithium borohydride / decaborane comprises the following steps:

[0044] At room temperature, in an argon glove box, weigh 150 mg of lithium borohydride powder and 350 m of decaborane powder, put them into agate and grind them evenly, and put the uniformly mixed product into a ball mill tank for high-energy hydrogen-filled ball milling Carry out the ball milling process: the ball-to-material ratio is 40:1, the ball milling speed is 300rpm, the ball milling time is 2h, and the hydrogen charging pressure is 4Mpa. The uniform mixture after ball milling is placed in a high temperature and high pressure sintering resistance furnace for heating and heat preservation. Process parameters: 0.2Mpa argon protection, temperature rise 5°C / min, target temperature and holding temperature 200°C, holding time 15h, cooling with the furnace. The product after cooling is 30 wt% lithium borohydride / decaborane. The schematic diagram of the solid electrolyte preparatio...

Embodiment 3

[0048] The preparation of 40wt% lithium borohydride / decaborane comprises the following steps:

[0049] At room temperature, in an argon glove box, weigh 200 mg of lithium borohydride powder and 300 m of decaborane powder, put them into agate and grind them evenly, and put the uniformly mixed product into a ball mill tank for high-energy hydrogen-charged ball milling Carry out the ball milling process: the ball-to-material ratio is 40:1, the ball milling speed is 300rpm, the ball milling time is 2h, and the hydrogen charging pressure is 4Mpa. The uniform mixture after ball milling is placed in a high temperature and high pressure sintering resistance furnace for heating and heat preservation. Process parameters: 0.2Mpa argon protection, temperature rise 5°C / min, target temperature and holding temperature 200°C, holding time 15h, cooling with the furnace. The product after cooling is 40 wt% lithium borohydride / decaborane. The schematic diagram of the solid electrolyte preparati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com