Ultrafiltration membrane cleaning agent and cleaning method thereof

A technology of ultrafiltration membrane and cleaning agent, which is applied in ultrafiltration, chemical instruments and methods, membranes, etc., can solve the problems of short service life, frequent cleaning, and insignificant effect, and achieve the effect of improving cleaning effect and temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

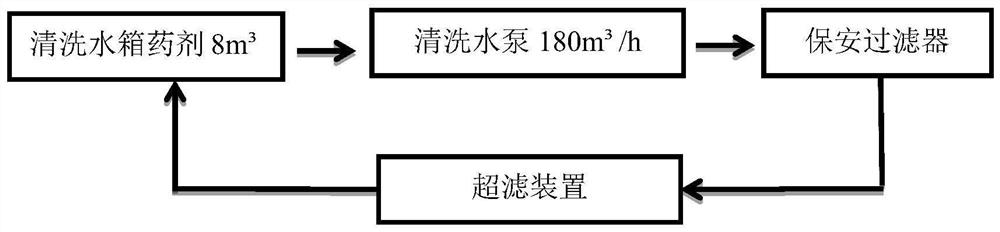

[0063] Example 1: Independent research on cleaning method one

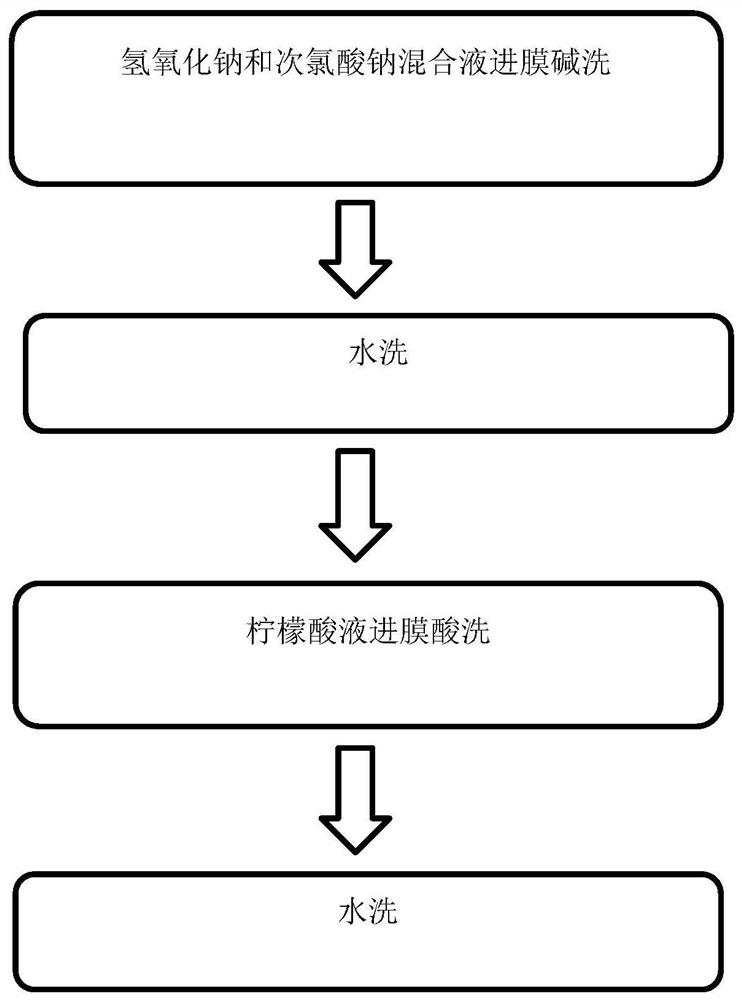

[0064] (1) a, alkali cleaning agent proportioning: sodium hypochlorite 625ppm (10wt% sodium hypochlorite 50kg), industrial sodium hydroxide (99wt%) 10kg, mixing and preparing cleaning liquid 8m 3 . b. Preparation of pickling agent: 100kg of citric acid, made into cleaning solution 8m 3 .

[0065] (2) Alkali washing: according to the steps (2) and (3) of Comparative Example 1, the medicine feeding cycle and the soaking operation were performed twice.

[0066] (3) Flushing: perform venting, backwashing, and positive flushing operations according to step (5) of Comparative Example 1, and the effluent pH of the extensive pH test paper detection system is <8.

[0067] (4) Citric pickling: according to the step (2) and step (3) of comparative example 1, the medicine feeding cycle and the soaking operation were performed twice.

[0068] (5) Flushing: perform venting, backwashing, and positive flushing operations acco...

Embodiment 2

[0071] Embodiment 2: Self-research cleaning method 2

[0072] (1) a, alkali cleaning agent proportioning: sodium hypochlorite 625ppm (10wt% sodium hypochlorite 50kg), industrial sodium hydroxide (99wt%) 10kg, mixing and preparing cleaning solution 8m 3 ; b. Preparation of pickling agent: 100kg of citric acid, made into 8m of cleaning solution 3 .

[0073] (2) Alkaline cleaning: add 50% water to the cleaning water tank, open the low-pressure steam valve, wait for the water temperature of the water tank to rise to 25°C, add sodium hypochlorite and sodium hydroxide into the water tank respectively, and then add water to make 8m 3 . Control the opening of the steam valve to keep the water temperature at 25-30°C. According to step (2) and step (3) of comparative example 1, the medicine feeding cycle and soaking are performed twice.

[0074] (3) Flushing: perform venting, backwashing, and positive flushing operations according to step (5) of Comparative Example 1, and the efflue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com