Porous composite membrane for air purification and preparation method thereof

A porous composite membrane, air purification technology, applied in the field of air purification, can solve the problems of air purification components pollution, body damage, entering the human circulatory system, etc., and achieve good bacteriostatic effect and prevent reproduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

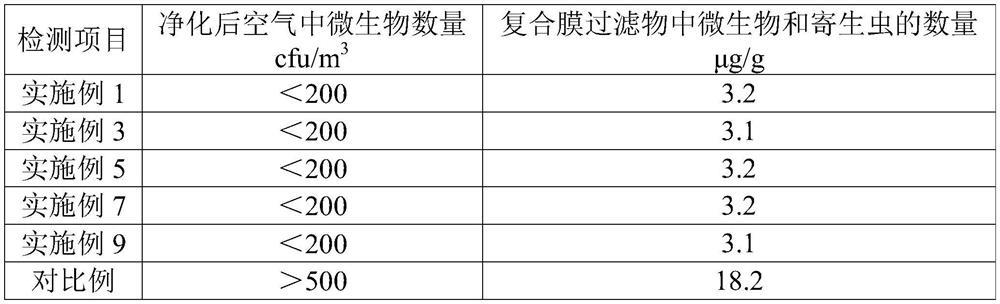

Examples

Embodiment 1

[0030] Weigh 1kg of polyvinyl chloride, measure 1L of methanol and 2L of dichloromethane, mix them to obtain the first solvent, mix the polyvinyl chloride and the first solvent, put them into the reaction kettle, raise the temperature to 55°C, keep stirring for 2 hours, and obtain the film-forming liquid.

[0031] Then weigh 1kg of Na 7 PMo 11 NiO 40 , Measure 5L of dichloromethane, mix Na 7 PMo 11 NiO 40 and dichloromethane to obtain an atmospheric liquid.

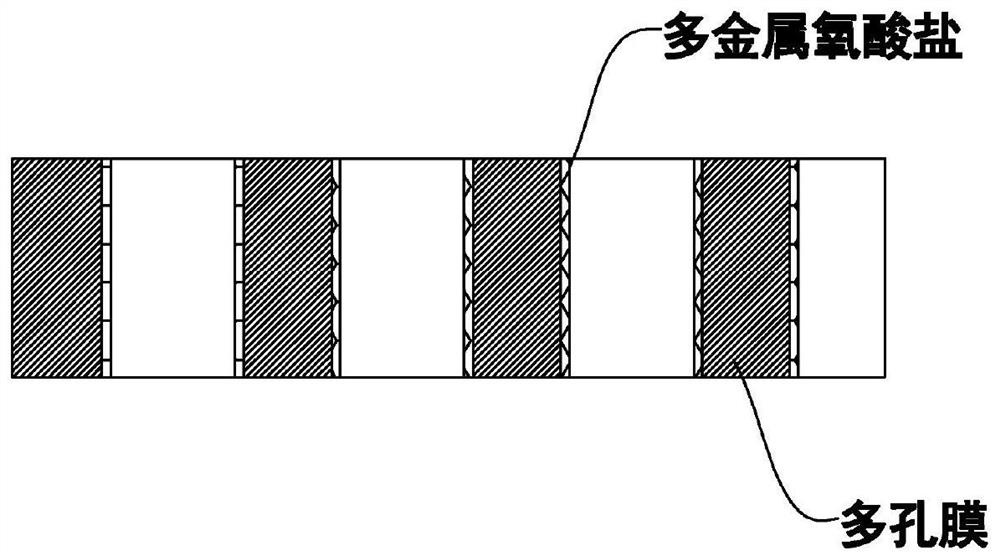

[0032] Nitrogen at 45°C passes through the atmosphere liquid and then blows to the surface of the non-woven fabric, and coats the film-forming solution on the surface of the non-woven fabric with a thickness of no more than 1 mm. After the solvent on the surface of the non-woven fabric is dried, a composite film is obtained . The profile structure is as figure 1 shown.

Embodiment 2

[0034] Weigh 1kg of polyvinyl chloride, measure 1L of methanol and 2L of dichloromethane, mix them to obtain the first solvent, mix the polyvinyl chloride and the first solvent, put them into the reaction kettle, raise the temperature to 55°C, keep stirring for 2 hours, and obtain the film-forming liquid.

[0035] Then weigh 1kg of Na 7 PMo 11 NiO 40 , Measure 5L of dichloromethane, mix Na 7 PMo 11 NiO 40 and dichloromethane to obtain an atmospheric liquid.

[0036] Nitrogen at 45°C passes through the atmosphere liquid and then blows to the surface of the non-woven fabric, and coats the film-forming solution on the surface of the non-woven fabric with a thickness of no more than 1 mm. After the solvent on the surface of the non-woven fabric is dried, a composite film is obtained .

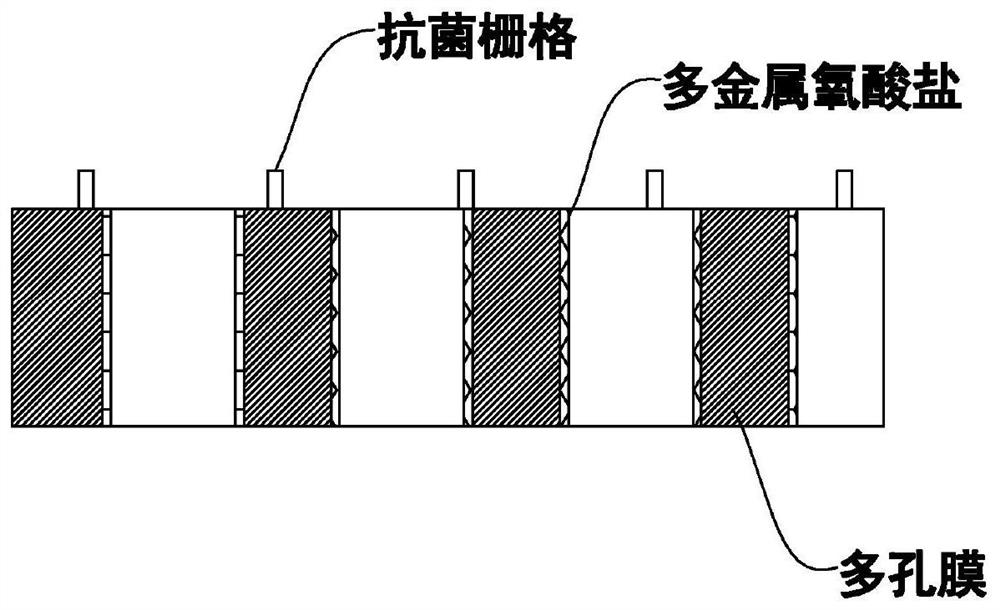

[0037] Then weigh 1kg polyisonitrile and 500ml DMF, mix and stir to dissolve to obtain a polyisonitrile solution, coat the polyisonitrile solution on the surface of the polyvinyl chloride la...

Embodiment 3

[0039] Weigh 1kg of polyvinyl chloride, measure 1L of methanol and 3L of chloroform, mix them to obtain the first solvent, mix the polyvinyl chloride and the first solvent, put them into the reaction kettle, raise the temperature to 58°C, keep stirring for 2 hours, and obtain the film-forming liquid.

[0040] Then weigh 1kg of Na 7 PMo 11 MnO 40 , Measure 6L chloroform, mix Na 7 PMo 11 MnO 40 and chloroform to obtain an atmospheric liquid.

[0041] The nitrogen gas at 48°C passes through the atmosphere liquid and then blows to the surface of the non-woven fabric, and the film-forming liquid is coated on the surface of the non-woven fabric with a thickness of no more than 1mm. After the solvent on the surface of the non-woven fabric is dried, a composite film is obtained .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com