Threshold beam structure of fuel cell hydrogen energy automobile

A fuel cell and threshold beam technology, which is applied to the superstructure, superstructure sub-assemblies, vehicle components, etc., can solve problems such as the obvious impact on the battery life of new energy vehicles, complicated welding and coating processes, and poor sealing and corrosion resistance. , to achieve the effect of simple and reliable connection method, simplified welding and coating process, and low mold input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

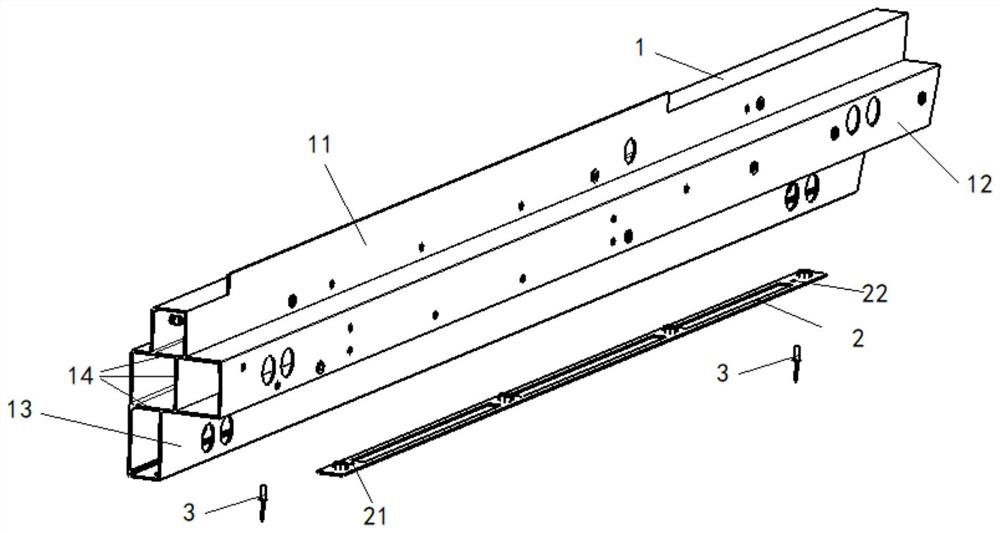

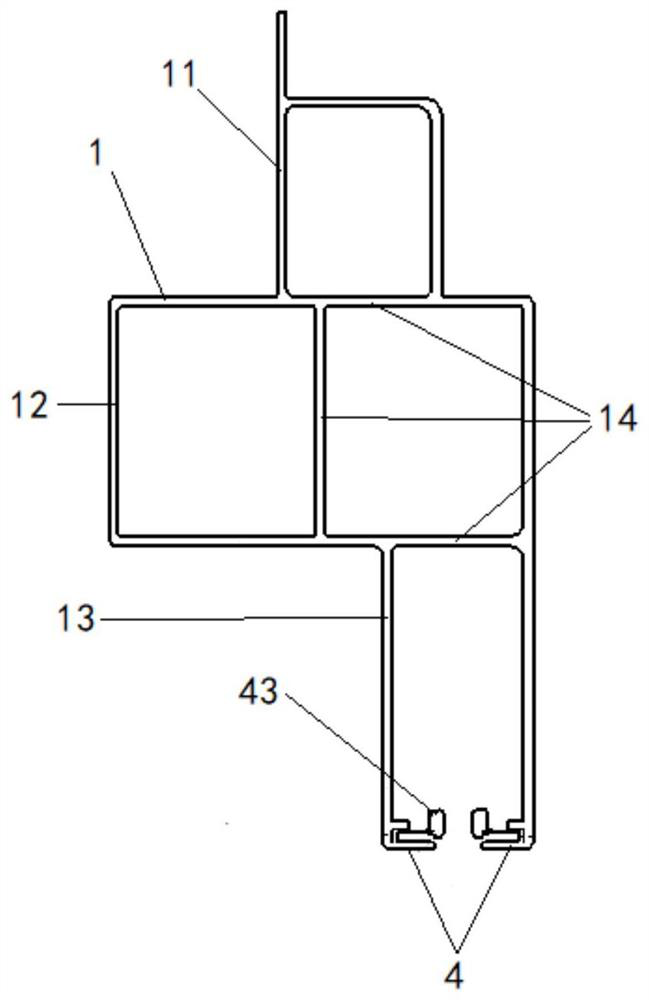

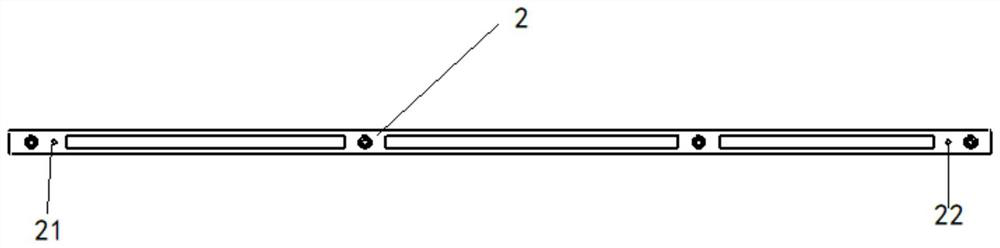

[0023] Please refer to Figure 1-3 , the present invention provides a sill beam structure for a fuel cell hydrogen energy vehicle, comprising: a sill beam 1 and a limiting plate 2 for installing a hydrogen bottle frame;

[0024] The interior of the sill beam 1 is a cavity structure that runs through the whole, and a plurality of reinforcing ribs 14 are arranged in the cavity; the lower bottom surface of the sill beam 1 is provided with a limit groove 4, and the limit plate 2 is installed on the hydrogen bottle frame. It is equipped to be inserted into the installation limit groove 4 for fixed installation.

[0025] Further, the two installation limit grooves 4 are used together when the bolts are tightened, and the hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com