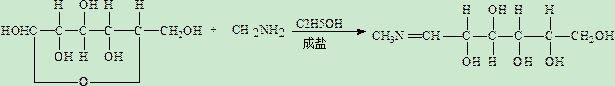

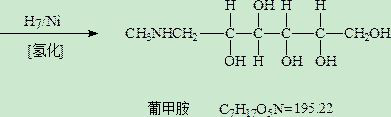

Meglumine production process

A production process and technology of meglumine, applied in the field of meglumine production technology, can solve the problems of slow reaction, low production efficiency, etc., and achieve the effects of improving conversion rate, improving production efficiency, and high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0039] The preparation steps of skeleton nickel are:

[0040] In the aluminum-nickel-chromium-rhodium alloy, by parts by weight, aluminum is 39%, nickel is 48%, chromium is 7%, rhodium is 6%, and the aluminum-nickel-chromium-rhodium alloy is 80-100 mesh.

[0041] The preparation steps of the aluminum-nickel-chromium-rhodium alloy are: melting aluminum at 800°C, melting rhodium, nickel, and chromium at a temperature of 2500°C, and then adding the molten rhodium, nickel, and chromium to the molten aluminum, stirring evenly, and cooling , and then the alloy is melted, sprayed, and rapidly cooled by a spray method to obtain an aluminum-nickel-chromium-rhodium alloy.

[0042] Stir the 23wt% sodium hydroxide solution and raise the temperature to 47°C, then gradually add Al-Ni-Cr-R alloy powder, the mass ratio of Al-Ni-Cr-R alloy to lye is 1:4.5, naturally raise the temperature to 100°C, and keep at this temperature for 2.5 After one hour, let cool to 65°C, stop stirring, wash repea...

preparation example 2

[0044] The difference from Preparation Example 1 is that in the aluminum-nickel-chromium-rhodium alloy, in parts by weight, aluminum is 50%, nickel is 40%, chromium is 3%, and rhodium is 7%.

[0045] Stir the 25wt% sodium hydroxide solution and raise the temperature to 43°C, then gradually add the Al-Ni-Cr-R alloy powder, the mass ratio of the Al-Ni-Cr-R alloy to the lye is 1:5, naturally raise the temperature to 90°C, and keep the temperature at 2.6 After one hour, let cool to 60°C, stop stirring, wash repeatedly with water until pH is 7, then wash with absolute ethanol until the content of ethanol in the feed liquid is 96% and discharge.

preparation example 3

[0047] The difference with Preparation Example 1 is:

[0048] The difference from Preparation Example 1 is that in the aluminum-nickel-chromium-rhodium alloy, by weight parts, aluminum is 52%, nickel is 38%, chromium is 2%, and rhodium is 8%.

[0049] Stir the 28wt% sodium hydroxide solution and raise the temperature to 40°C, then gradually add the aluminum-nickel-chromium-rhodium alloy powder, the mass ratio of the aluminum-nickel-chromium-rhodium alloy to the lye is 1:5.5, naturally heat up to 85°C, and keep at this temperature for 3 After one hour, let cool to 55°C, stop stirring, wash repeatedly with water until pH is 7, then wash with absolute ethanol until the content of ethanol in the feed liquid is 98% and discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com