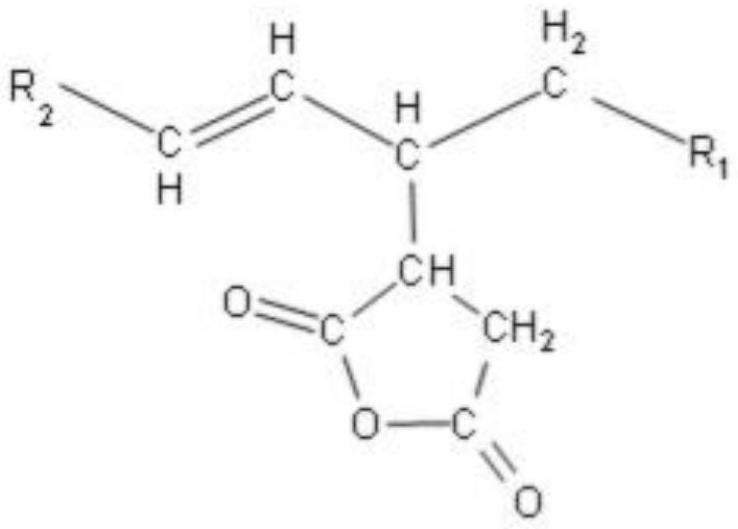

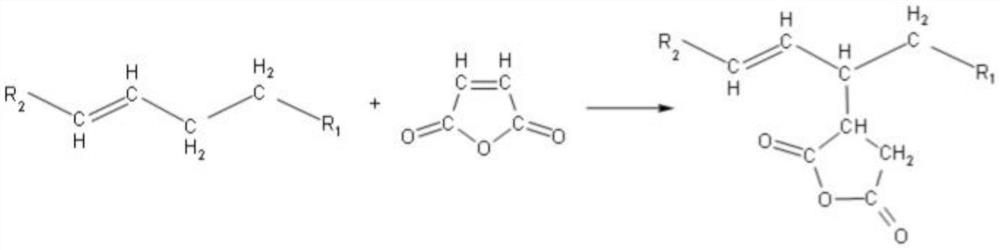

Preparation method and application of high-purity alkenyl succinic anhydride

An alkenyl succinic anhydride, high-purity technology, applied in chemical instruments and methods, textiles and papermaking, chemical/physical/physicochemical reactors, etc., can solve problems such as large footprint, high energy consumption, and complex equipment, and achieve The effects of small footprint, low energy consumption, and simple equipment operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Add 70 parts of C18 internal olefins, 30 parts of C16 internal olefins and 1 part of antioxidant p-hydroxyanisole into tank 1 and mix well. Add 30 parts of maleic anhydride to tank 2 and heat to 65°C to melt into a liquid. The heating medium of the microchannel reactor was raised to 245° C. and the cycle was started. Add the liquid in tank 1 and tank 2 to the feed port of the microchannel reactor with a metering pump, the feeding speed ratio is 101:30, the residence time of the material in the microchannel reactor is 10 minutes, and the reaction product reacts from the microchannel The discharge port of the rectification tower continuously flows out and enters the middle of the rectification tower for rectification. Unreacted internal olefins, etc. are obtained at the top of the rectification tower, which can be recycled and reused. The refined ASA product is obtained at the bottom of the rectification tower, which enters the finished product storage tank after cooling ...

Embodiment 2

[0036] Add 54 parts of C18 internal olefins, 33 parts of C16 internal olefins and 2 parts of antioxidant p-hydroxyanisole into tank 1 and mix well. Add 30 parts of maleic anhydride to tank 2 and heat to 80°C to melt into a liquid. The heating medium of the microchannel reactor was raised to 260° C. and the cycle was started. Add the liquid in tank 1 and tank 2 to the feed port of the microchannel reactor with a metering pump, the feed rate ratio is 90:30, the residence time of the material in the microchannel reactor is 5 minutes, and the reaction product reacts from the microchannel The discharge port of the rectification tower continuously flows out and enters the middle of the rectification tower for rectification. Unreacted internal olefins, etc. are obtained at the top of the rectification tower, which can be recycled and reused. The refined ASA product is obtained at the bottom of the rectification tower, which enters the finished product storage tank after cooling .

Embodiment 3

[0038] Add 80 parts of C18 internal olefins, 8 parts of C16 internal olefins and 2 parts of antioxidant p-hydroxyanisole into tank 1 and mix well. Add 28 parts of maleic anhydride to tank 2 and heat to 90°C to melt into a liquid. The heating medium of the microchannel reactor was raised to 295° C. and the cycle was started. Add the liquid in tank 1 and tank 2 to the feed port of the microchannel reactor with a metering pump, the feeding speed ratio is 90:28, the residence time of the material in the microchannel reactor is 1 minute, and the reaction product reacts from the microchannel The discharge port of the rectification tower continuously flows out and enters the middle of the rectification tower for rectification. Unreacted internal olefins, etc. are obtained at the top of the rectification tower, which can be recycled and reused. The refined ASA product is obtained at the bottom of the rectification tower, which enters the finished product storage tank after cooling . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com