Compound enzyme digestive juice as well as preparation method and application thereof

A digestive juice and compound enzyme technology, applied in the field of compound enzyme digestive liquid and its preparation, can solve the problems of reduced cell activity, morphological rupture, single composition, etc., and achieve the effects of low cell death rate, short digestion time and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

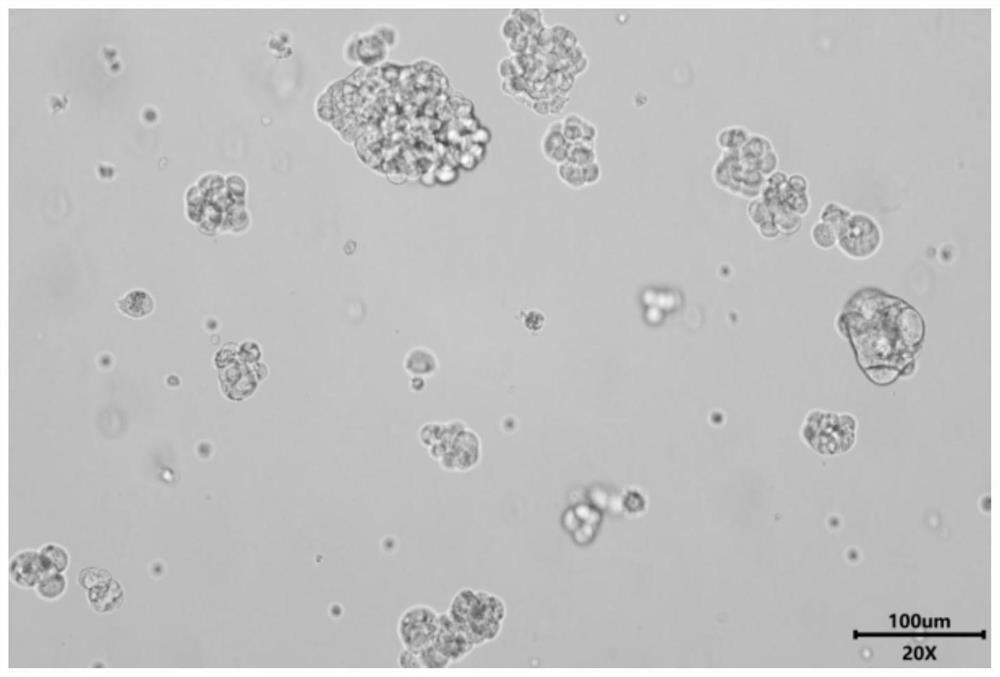

Embodiment 1

[0052] This embodiment provides a compound enzyme digestion solution, including the following components at the final concentration: type IV collagenase 200U / mL, type II dispase 2U / ml, deoxyribonuclease 20U / ml, PMSF 0.1mM, ethylene glycol 10 wt%, polysucrose 10 wt%, the solvent is sterile water; the pH of the digestive juice is 7.4. The preparation method of the digestive juice comprises: batching ingredients according to the final concentration of each component of the digestive juice; Mix the diol evenly; adjust the pH to 7.4, filter and sterilize, and store the digestive juice in a -20°C refrigerator for later use.

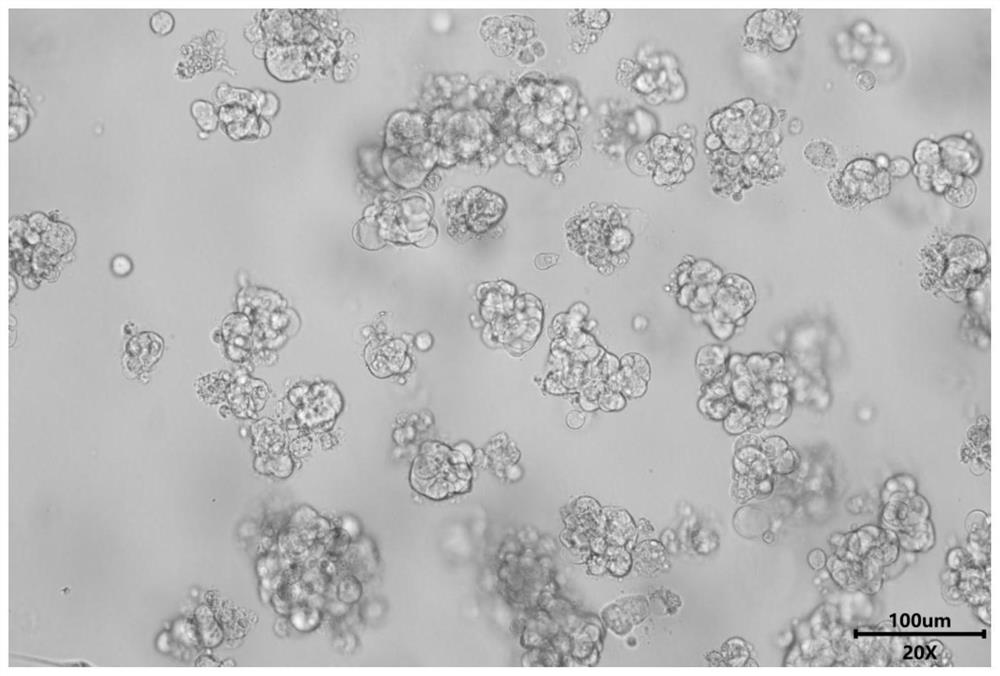

Embodiment 2

[0054] This embodiment provides a compound enzyme digestion solution, which is different from Embodiment 1 in that it also includes: CaCl 2 2mM, MgCl 2 1mM. The preparation method of the digestive juice comprises: batching ingredients according to the final concentration of each component of the digestive juice; 2 , MgCl 2 1. Dissolve polysucrose in sterile water, then add ethylene glycol and mix evenly; adjust the pH to 7.4, filter and sterilize, and store the digestive juice in a -20°C refrigerator for later use.

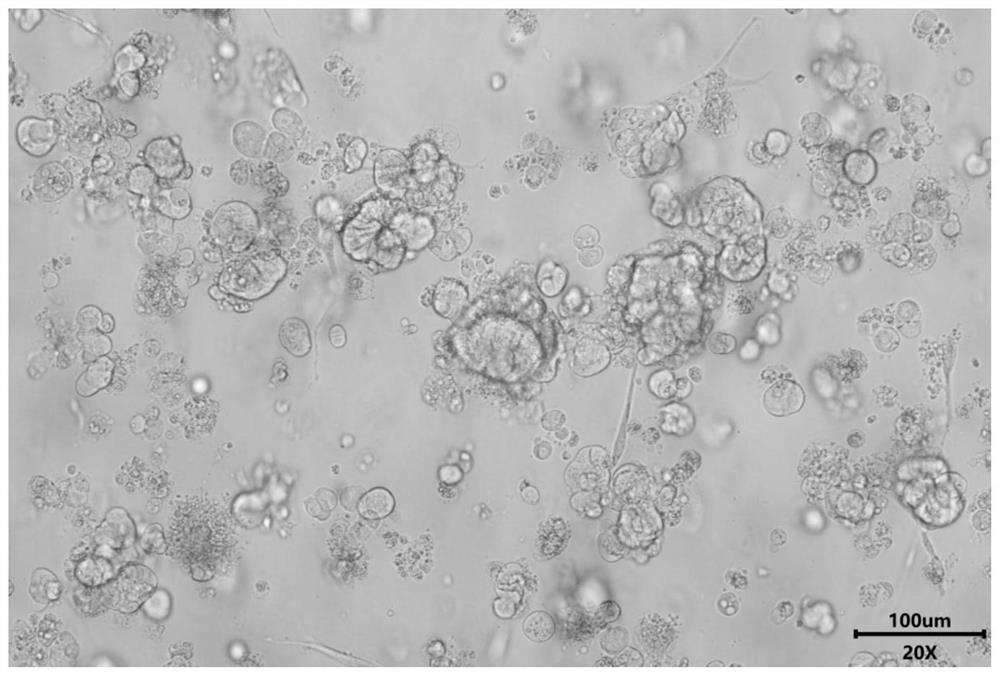

Embodiment 3

[0056] This embodiment provides a compound enzyme digestion solution, which differs from that of Embodiment 1 in that it also includes: 1 wt% glycerin. The preparation method of the digestive juice comprises: batching ingredients according to the final concentration of each component of the digestive juice; Glycol and glycerin are mixed evenly; adjust the pH to 7.4, filter and sterilize, and store the digestive juice in a -20°C refrigerator for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com