Technology and process for treating organic solid waste through self-balancing fermentation and incineration

A self-balancing technology for organic solid waste, applied in fermentation, biological sludge treatment, incinerators, etc., can solve the problems of incomplete incineration, high operating costs, and high reduction rate, and achieve high volume reduction rate of solid waste , short digestion time, and the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

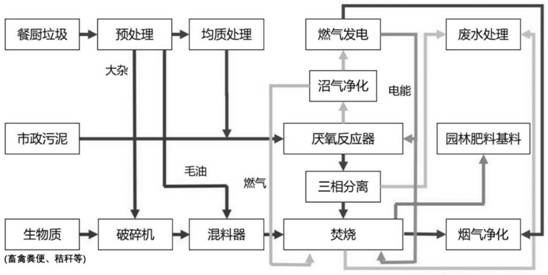

[0036] A self-balancing fermentation and incineration technology and process for treating organic solid waste, characterized in that it mainly includes an anaerobic fermentation system, a gas-fired power generation system, and an incineration system; each of the above-mentioned systems is used to construct a self-balancing fermentation and incineration treatment system for processing Kitchen waste (organic solid waste), crop straw (waste used for auxiliary combustion, that is, biomass), municipal sludge;

[0037] The food waste is pretreated (screened and pretreated) and divided into large miscellaneous solid waste (particle size > 100mm), crude oil and small particle size solid waste (particle size ≤ 100mm).

[0038] The CSJ type coarse pulverizer is used to crush, stir, mix and homogenize the small-sized solid waste. The particle size of the solid waste after treatment ranges from 0.5 to 20mm, and it is mixed with municipal sludge and sent to the anaerobic fermentation system...

Embodiment 2

[0044] A self-balancing fermentation and incineration technology and process for treating organic solid waste, characterized in that it mainly includes an anaerobic fermentation system, a gas-fired power generation system, and an incineration system; each of the above-mentioned systems is used to construct a self-balancing fermentation and incineration treatment system for processing Vegetable waste (organic solid waste), crop straw (waste used for auxiliary combustion, that is, biomass), municipal sludge;

[0045] After pretreatment (screening pretreatment), the vegetable farm waste is divided into large miscellaneous solid waste (particle size after rolling and pressing > 100mm), crude oil and small particle size solid waste (particle size after rolling and pressing ≤ 100mm).

[0046]The CSJ type coarse pulverizer is used to crush, stir, mix and homogenize the small-sized solid waste. After the treatment, the particle size of the solid waste ranges from 0.5 to 20mm, and it is...

Embodiment 3

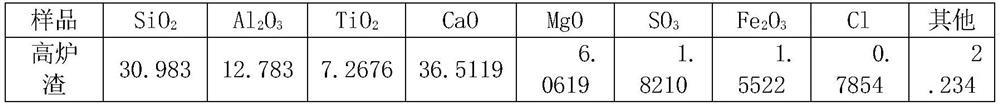

[0052] A self-balancing fermentation and incineration technology and process for treating organic solid waste, characterized in that it mainly includes an anaerobic fermentation system, a gas-fired power generation system, and an incineration system; each of the above-mentioned systems is used to construct a self-balancing fermentation and incineration treatment system for processing Garden waste (organic solid waste), slag (waste used for auxiliary combustion), municipal sludge;

[0053] The garden waste is pretreated (screened pretreatment) and divided into large miscellaneous solid waste (particle size after rolling and pressing > 100mm), crude oil and small particle size solid waste (particle size after rolling and pressing ≤ 100mm).

[0054] The CSJ type coarse pulverizer is used to crush, mix and homogenize the small-sized solid waste. The particle size of the solid waste after treatment ranges from 0.5 to 20mm, and it is mixed with municipal sludge and sent to the anaero...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com