Animal slaughter house garbage treatment method and device thereof

A processing method and technology of a processing device, which are applied in the methods of biological material sampling, biomass post-processing, and biological material pretreatment, etc., can solve the problem of reducing the utilization rate of waste resources in slaughterhouses, increasing the difficulty of removing biogas residues, and reducing the efficiency of waste treatment. and other problems, to achieve the effect of promoting fermentation efficiency and gas production, improving combustion stability and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

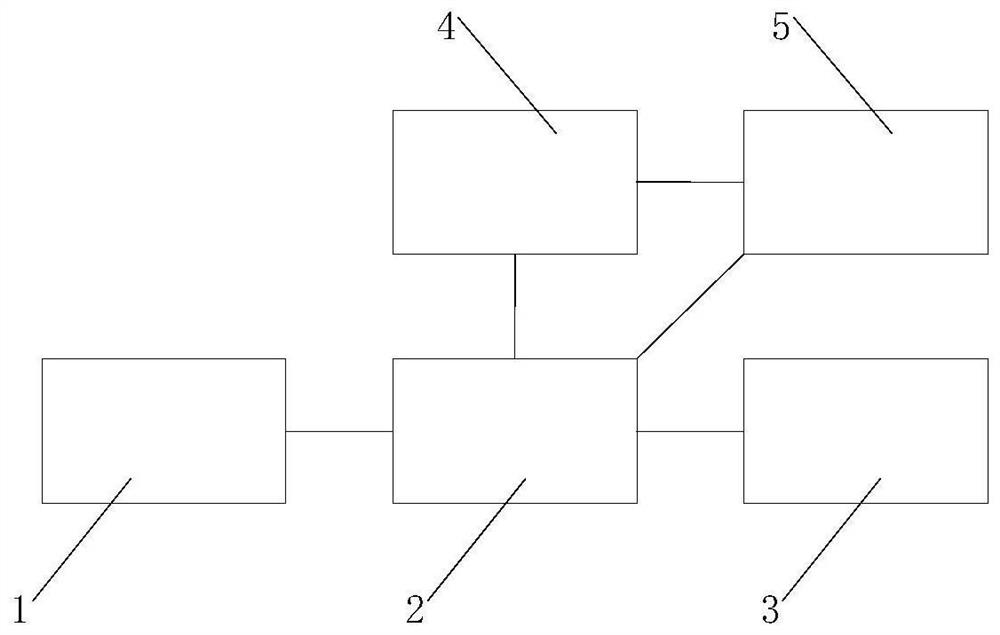

[0031] Example. A treatment method for animal slaughterhouse waste, which consists of figure 1 shown, including the following steps:

[0032] ① Mix the waste from the slaughterhouse and the green material waste and then crush it to within 1mm. The mixture must not contain harmful components such as waste paint and waste ink;

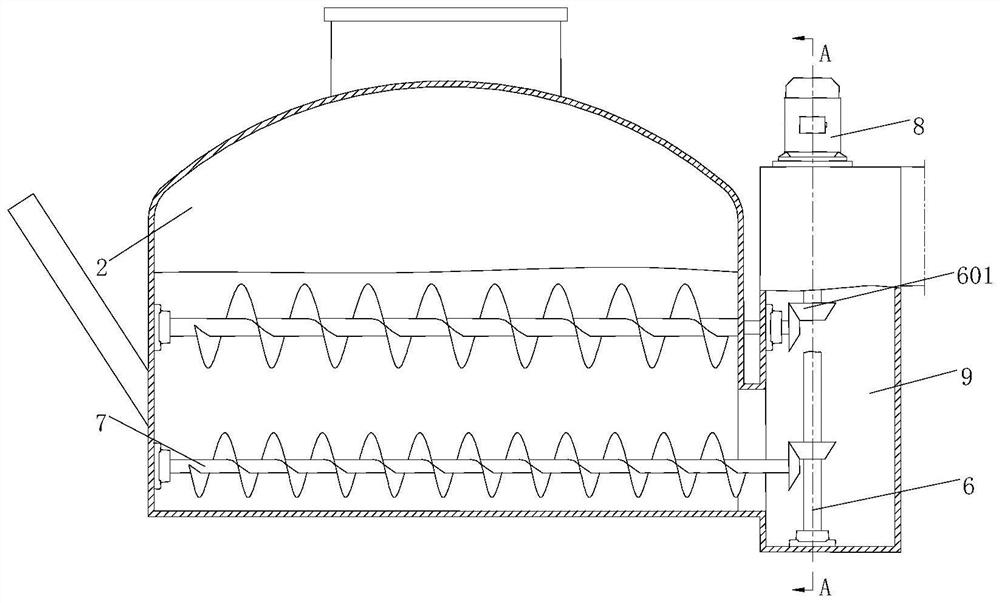

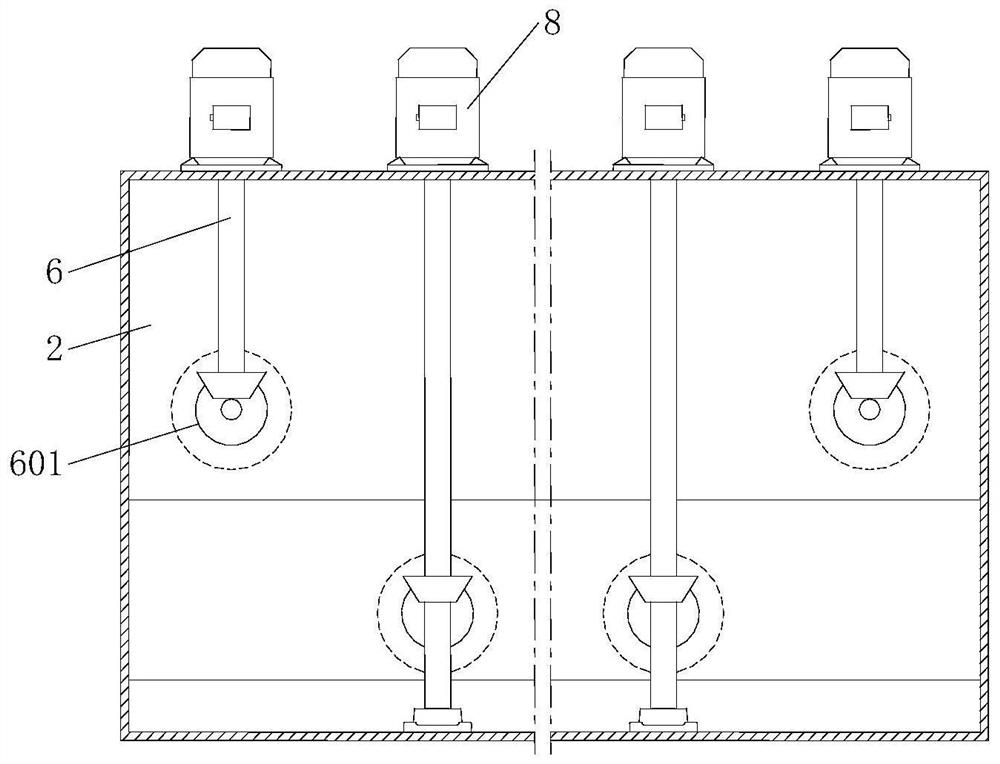

[0033] ②Send the crushed mixed material and hydrolyzed solution together into the biogas digester, and ferment in a negative pressure environment of 45-58°C;

[0034] ③Collect the biogas produced after the mixture is fermented, then mix the biogas with the combustion-supporting gas and burn it, and provide part of the heat generated by the combustion to the biogas pit for heating;

[0035] ④ Collect the mixed material after fermentation and use it as plant watering material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com