Prussian blue redox derived iron-based wave-absorbing material and preparation method thereof

A wave absorbing material, Prussian blue technology, applied in electrical components, magnetic field/electric field shielding, etc., can solve the problem of narrow effective absorption frequency band, achieve the effect of simple and feasible, meet design requirements, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The specific preparation steps of a Prussian blue redox-derived iron-based wave-absorbing material are as follows:

[0029] (1): Add 15.2 g of polyvinylpyrrolidone and 1.7 mL of hydrochloric acid into 200 mL of deionized water, stir to dissolve, add 0.44 g of ferrous potassium chloride and stir for 30 min, seal the beaker and put it in 80 o C oven insulation reaction for 24 h; the reacted product was filtered, washed and dried to obtain Prussian blue powder. Prussian blue powder is a blue powder with the molecular formula Fe 4 [Fe(CN) 6 ] 3 , the particles are cube-shaped with a particle size of 400-800 nm.

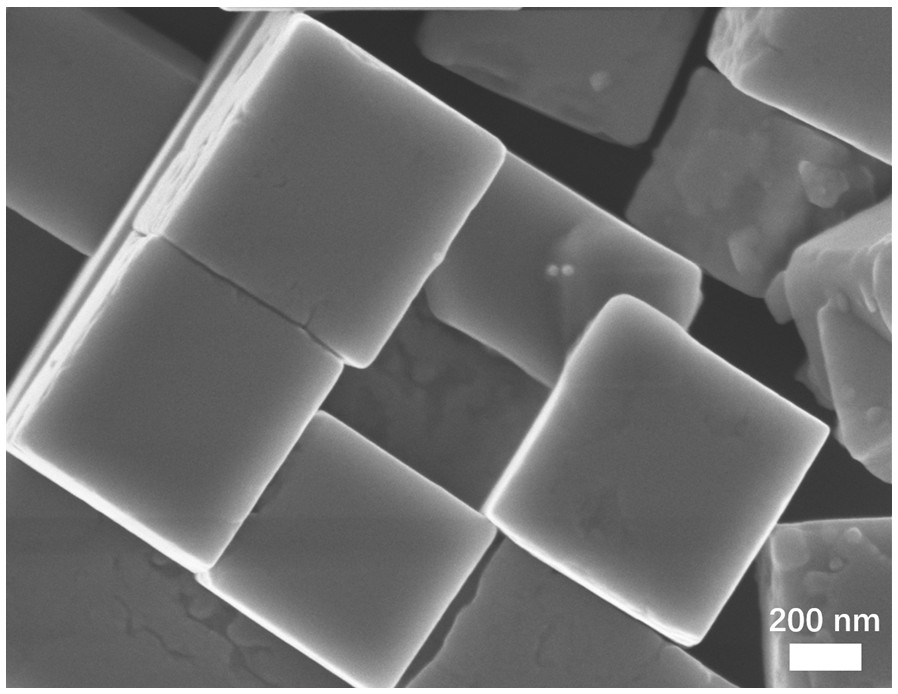

[0030] see figure 1 , the particles of the prepared Prussian blue powder have obvious cubic shape and smooth surface, and the average particle size is about 500 nm.

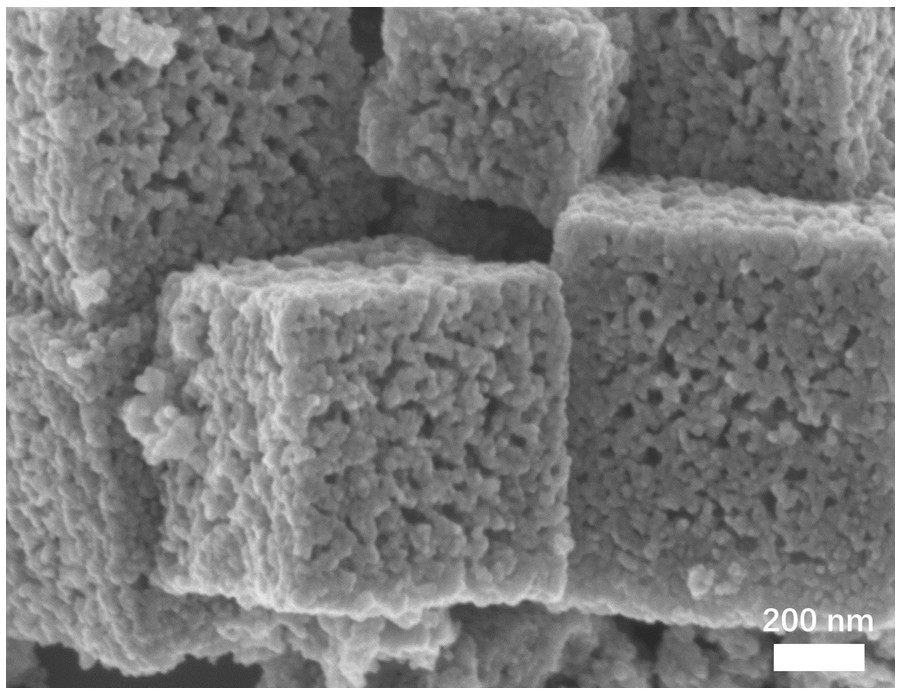

[0031] (2): Put Prussian blue powder in the air at 2 o C / min heating rate increased to 350 o C and keep it warm for 6 h, cool down naturally to get ferric oxide (Fe 2 o 3 )powder. Ferric oxi...

Embodiment 2

[0040] The specific preparation steps of a Prussian blue redox-derived iron-based wave-absorbing material are as follows:

[0041] (1): Add 15.2 g of polyvinylpyrrolidone and 1.7 mL of hydrochloric acid into 200 mL of deionized water, stir to dissolve, add 0.44 g of ferrous potassium chloride and stir for 30 min, seal the beaker and put it in 80 o C oven insulation reaction for 24 h; the reacted product was filtered, washed and dried to obtain Prussian blue powder. Prussian blue powder is a blue powder with the molecular formula Fe 4 [Fe(CN) 6 ] 3 , the particles are cube-shaped with a particle size of 400-800 nm.

[0042] (2): Put Prussian blue powder in the air at 2 o C / min heating rate increased to 350 o C and keep it warm for 6 h, cool down naturally to get ferric oxide (Fe 2 o 3 )powder. Ferric oxide powder is a deep red powder, and the particles are irregular cubes assembled from small particles, with a particle size of 200-800 nm.

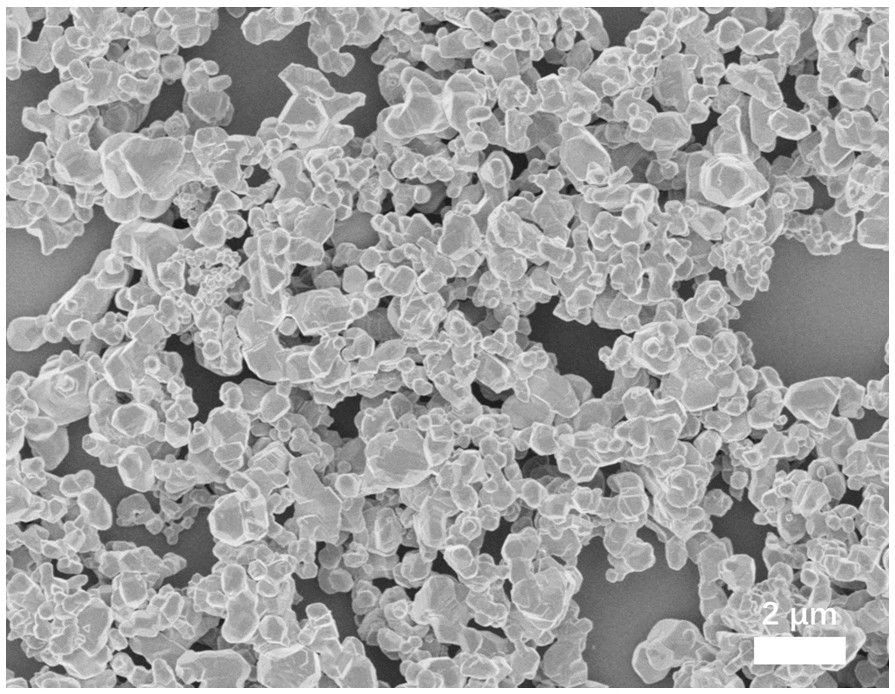

[0043] (3): Add 1 g of ferri...

Embodiment 3

[0049] (1): Add 15.2 g of polyvinylpyrrolidone and 1.7 mL of hydrochloric acid into 200 mL of deionized water, stir to dissolve, add 0.44 g of ferrous potassium chloride and stir for 30 min, seal the beaker and put it in 80 o C oven reaction for 24 h; the reacted product was filtered, washed and dried to obtain Prussian blue powder. Prussian blue powder is a blue powder with the molecular formula Fe 4 [Fe(CN) 6 ] 3 , the particles are cube-shaped with a particle size of 400-800 nm.

[0050] (2): Put Prussian blue powder in the air at 2 o C / min heating rate increased to 350 o C and keep it warm for 6 h, cool down naturally to get ferric oxide (Fe 2 o 3 )powder. Ferric oxide powder is a deep red powder, and the particles are irregular cubes assembled from small particles, with a particle size of 200-800 nm.

[0051] (3): 1 g of ferric oxide (Fe 2 o 3 ) powder into the mixed solution, the mixed solution was prepared by mixing 80 mL water, 32 mL absolute ethanol and 0.4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com