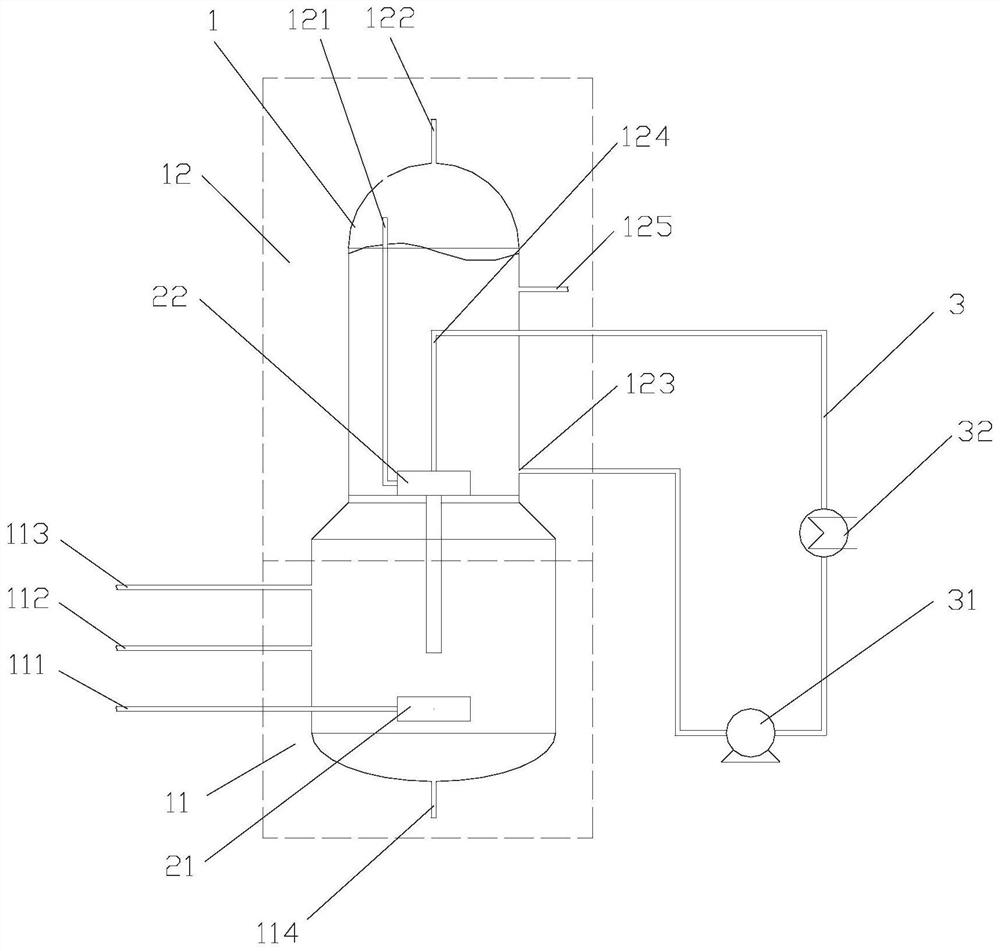

System and process for preparing epoxypropane based on micro-interface enhanced propylene epoxidation

A technology of propylene oxide and epoxidation, which is applied in chemical/physical/physical chemical processes, chemical/physical/physical chemical reactors, organic chemistry, etc., can solve the problem of low reaction efficiency of the system, and achieve improved reaction efficiency, The effect of ensuring the reaction rate and increasing the phase boundary area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Use above-mentioned system and process to carry out propylene oxide to prepare propylene oxide, wherein:

[0082] In the process, the reaction temperature in the reactor is 20°C, the reaction pressure is 0.1MPa, the molar ratio of propylene gas to oxygen source solution is 1.2:1, and the catalyst space velocity is 1.20h -1 .

[0083] The gas-liquid ratio in the first micro-interface generator is 1000:1, and the gas-liquid ratio in the second micro-interface generator is 400:1.

[0084] After testing, after using the system and process, H 2 o 2 The conversion rate of propylene gas is 97.2%, the conversion rate of propylene gas is 7.5%, and the selectivity of PO is 95.3%.

Embodiment 2

[0086] Use above-mentioned system and process to carry out propylene oxide to prepare propylene oxide, wherein:

[0087] In the process, the reaction temperature in the reactor is 35°C, the reaction pressure is 0.2MPa, the molar ratio of propylene gas to oxygen source solution is 1.5:1, and the catalyst space velocity is 1.05h -1 .

[0088] The gas-liquid ratio in the first micro-interface generator is 1150:1, and the gas-liquid ratio in the second micro-interface generator is 420:1.

[0089] After testing, after using the system and process, H 2 o 2 The conversion rate of propylene gas is 97.8%, the conversion rate of propylene gas is 7.7%, and the selectivity of PO is 95.6%.

Embodiment 3

[0091] Use above-mentioned system and process to carry out propylene oxide to prepare propylene oxide, wherein:

[0092] In the process, the reaction temperature in the reactor is 42°C, the reaction pressure is 0.5MPa, the molar ratio of propylene gas to oxygen source solution is 1.9:1, and the catalyst space velocity is 0.68h -1 .

[0093] The gas-liquid ratio in the first micro-interface generator is 1280:1, and the gas-liquid ratio in the second micro-interface generator is 490:1.

[0094] After testing, after using the system and process, H 2 o 2 The conversion rate of propylene gas is 98.1%, the conversion rate of propylene gas is 8.1%, and the selectivity of PO is 96.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com