Numerical control machine tool capable of draining water conveniently

A technology of CNC machine tools and machine tools, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of blockage of drainage pipes, inconvenient recycling of metal chips and cutting fluid, and lack of filtration of chips, etc. To achieve the effect of preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

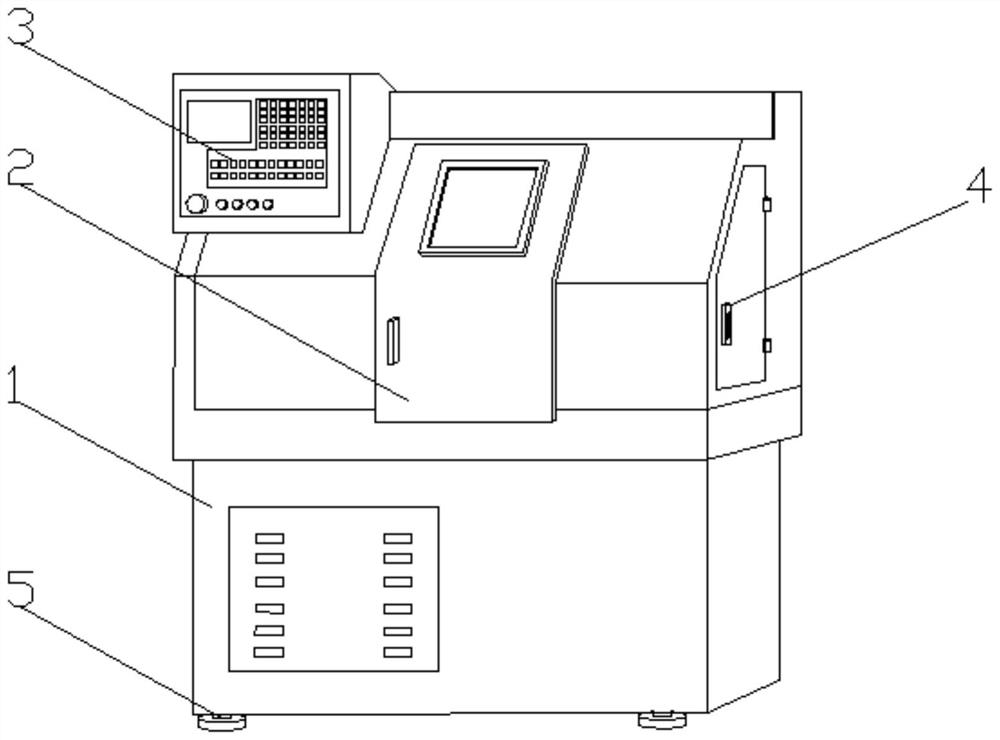

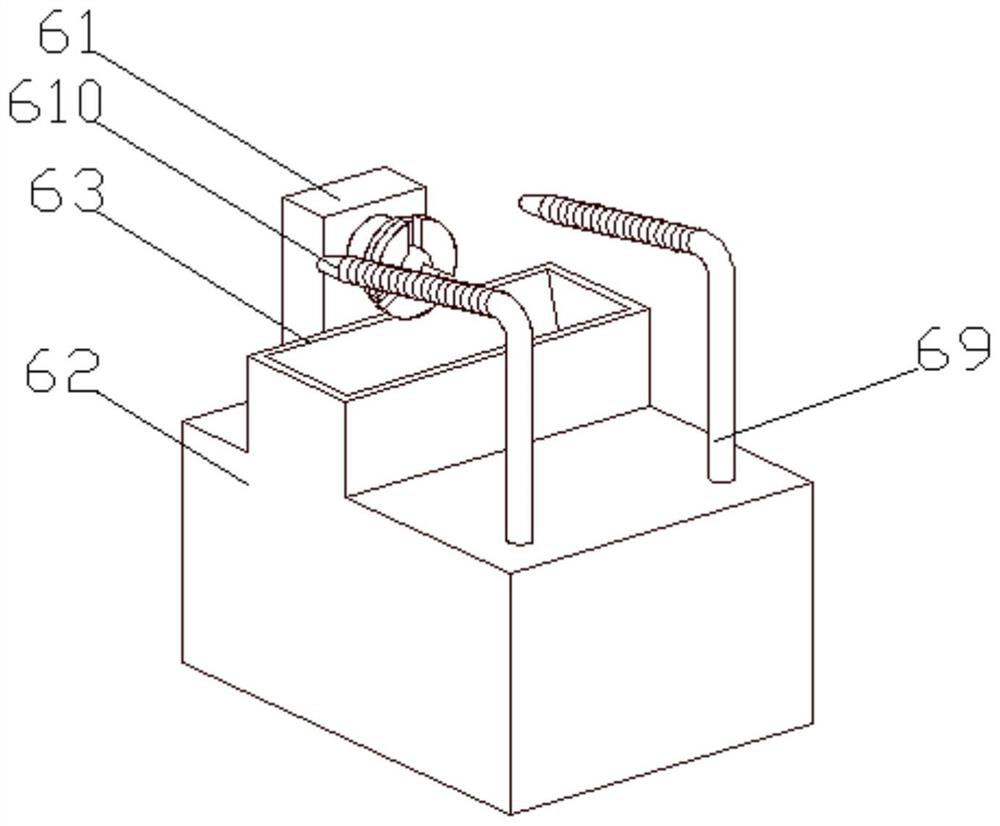

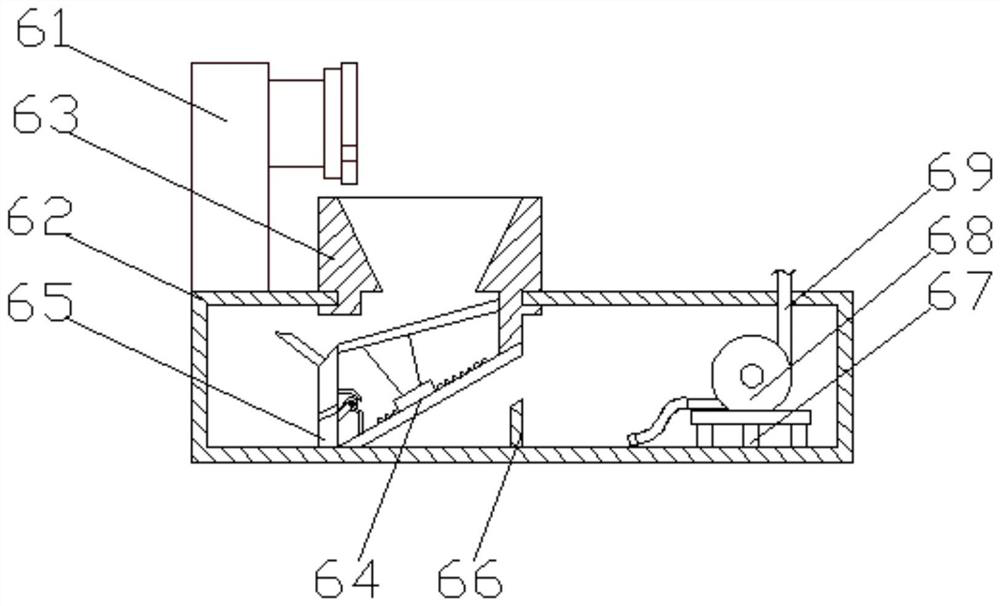

[0038] see Figure 1-3 , the present invention provides a technical solution: a numerically controlled machine tool that is convenient for drainage, including a machine tool shell 1, a machine tool sliding window 2 and a machine tool control panel 3 are arranged on one side of the machine tool shell 1, and one side of the machine tool shell 1 passes through The hinge is rotatably connected with a machine tool protection door panel 4, and the four corners of the bottom of the machine tool housing 1 are fixedly connected with protective pads 5, and a processing mechanism 6 is arranged inside the machine tool housing 1, and the processing mechanism 6 includes a machine tool processing device 61, one end of the machine tool processing device 61 A liquid storage case 62 is fixedly connected, and a liquid discharge bucket 63 is arranged on the top side of the liquid storage case 62 close to the machine tool processing device 61. The bottom of the inner wall of the liquid storage case...

Embodiment 2

[0040] see Figure 1-5 , on the basis of Embodiment 1, the present invention provides a technical solution: a numerically controlled machine tool that facilitates drainage, the first filter mechanism 64 includes a first filter plate a1, and a first through hole a2 is opened on the top of the first filter plate a1 , one side of the first filter plate a1 is provided with a through-hole mechanism a3, the end of the through-hole mechanism a3 away from the first filter plate a1 is provided with a second filter plate a4, and the side of the second filter plate a4 close to the through-hole mechanism a3 is fixed The rack a5 is connected, one side of the second filter plate a4 is provided with a communication port a6, the through hole mechanism a3 includes a through hole base shell a31, one side of the through hole base shell a31 is opened with a through groove a32, the through hole base The side of the inner wall of the housing a31 is fixedly connected with a circulation motor a33, th...

Embodiment 3

[0043] see Figure 1-9 , on the basis of Embodiment 2, the present invention provides a technical solution: a numerically controlled machine tool that facilitates drainage, the second filter mechanism 65 includes a fixed column b1, and a first drain hole b2 is opened on the top of the fixed column b1, and the fixed column b1 One side of b1 is provided with a first drainage groove b3, one side of the first drainage hole b2 is connected with a filter housing b4, and the side of the filter housing b4 away from the first drainage hole b2 is provided with a tapered through hole b5 One side of the filter housing b4 is fixedly connected with the first connecting frame b6, and the end of the first connecting frame b6 away from the filter housing b4 is connected with the first magnet b7 through the rotation of the electric control rolling roller, and the side of the first magnet b7 is provided with The first chip removal shovel b8, the end of the first chip removal shovel b8 away from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com