Method for preparing bionic hollow human body part model through 3D printing

A human body part, 3D printing technology, applied in processing and manufacturing, liquid material additive processing, household components, etc., can solve the problems of long model time, high cost, stitching, repeated tearing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

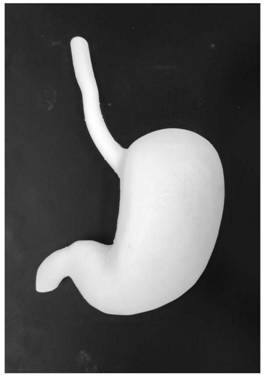

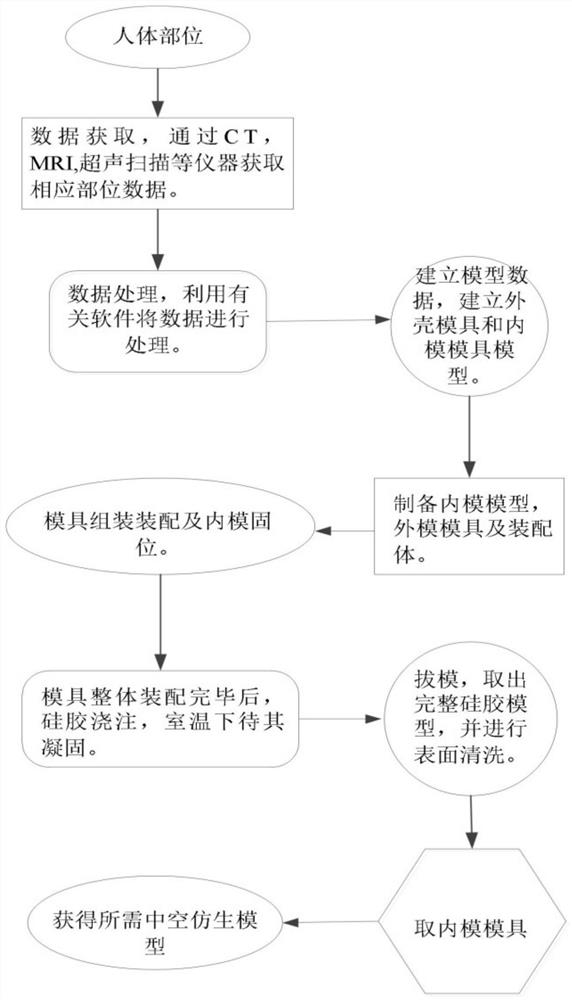

[0098] Such as figure 1 As shown, this embodiment realizes the preparation of the bionic hollow human stomach and esophagus model through the following steps:

[0099] 1. Data acquisition and extraction:

[0100] Scan the human stomach and esophagus model by scanning equipment (3D laser scanner) to obtain its point cloud data;

[0101] Because the model data in this embodiment is obtained from the existing gastroesophageal model, it is not necessary to obtain data from special medical images.

[0102] 2. Data processing and mold design:

[0103] Use software (Geomagics Studio) to process the point cloud data of the human gastroesophagus, making it a data format recognizable by a 3D printer that meets the requirements.

[0104] 3. Build a model:

[0105] Professionally painted Figure three Dimensional software (Solidworks, ProE, UG, Fluent) special modules, using the data obtained in step 2, to establish the shell mold model, hollow inner mold model and assembly mold mode...

Embodiment 2

[0121] This embodiment realizes the preparation of the bionic hollow human stomach and esophagus model through the following steps:

[0122] 1. Data acquisition and extraction:

[0123] Use medical imaging equipment, such as CT, MRI, PET-CT and ultrasound scanners, to detect the human gastroesophagus, obtain and save the corresponding image data, and extract and record the surface elastic modulus of the gastroesophagus;

[0124] 2. Data processing:

[0125] Import CT, MRI, PET-CT image data into Mimics, complete segmentation processing, and then repair the image data after segmentation processing by 3-matic and Magics, and then detect it by Geomagic data model to make it become three-dimensional data, which meets the requirements A data format that a 3D printer can recognize.

[0126] 3. Building a model

[0127] Professionally painted Figure three Dimensional software (Solidworks, ProE, UG, Fluent) special modules use the data obtained in step 2 to establish the shell mo...

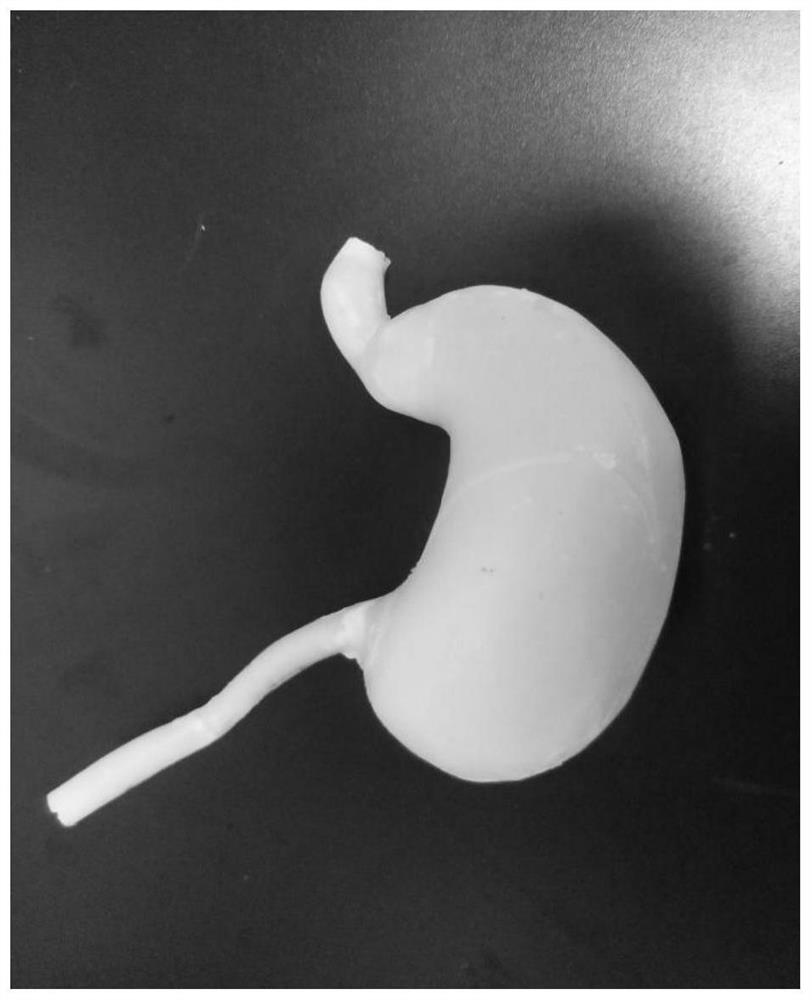

Embodiment 3

[0141] This embodiment realizes the preparation of the bionic hollow human stomach and esophagus model through the following steps:

[0142] 1. Obtain and extract data:

[0143] Use medical imaging equipment, such as CT, MRI, PET-CT and ultrasound scanners, to detect the human gastroesophagus, obtain and save the corresponding image data, and extract and record the surface elastic modulus of the gastroesophagus;

[0144] 2. Data processing:

[0145] Use medical software (Mimics, 3-matic, Magics, Geomagics) to process the human gastroesophageal image data obtained in step 1, and convert it into a data format that can be recognized by 3D printing equipment;

[0146] The specific processing process is: import CT, MRI, PET-CT, and image data into Mimics, complete the extraction and segmentation processing, and then repair the image data after segmentation processing by 3-matic and Magics, and then detect it by the Geomagic data model to make it a Three-dimensional data becomes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com