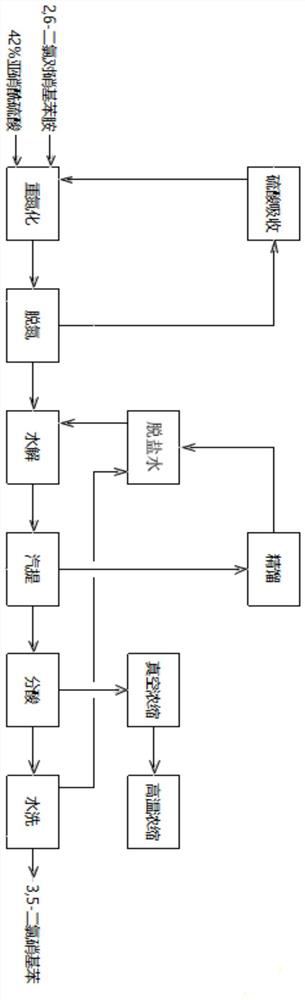

Production process of 3,5-dichloronitrobenzene

A technology of dichloronitrobenzene and production process, which is applied in the field of production technology of 3,5-dichloronitrobenzene, can solve the problems of pollution, low synthesis yield and the like, and achieves high yield, low cost and cost saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

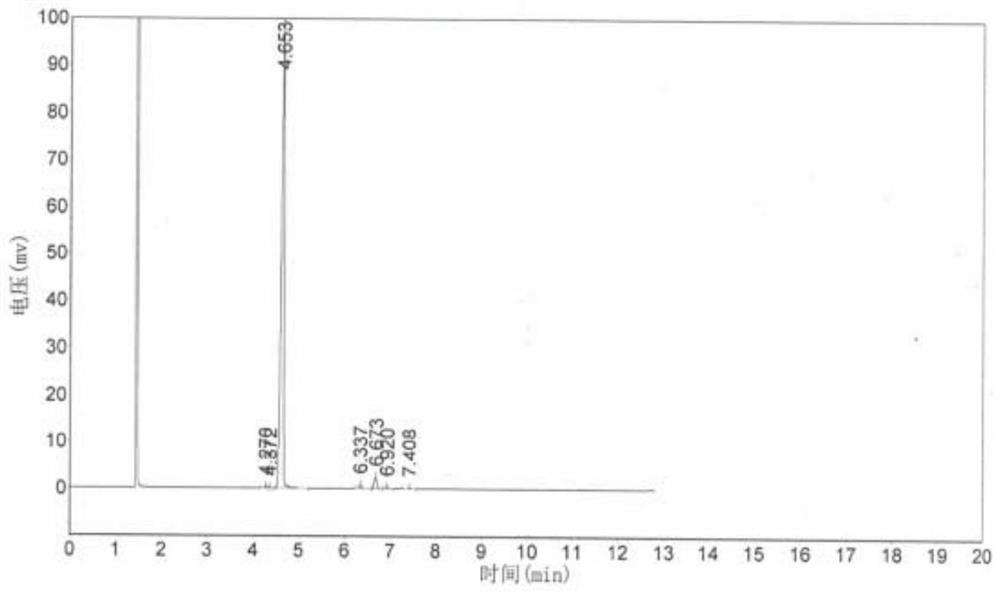

Embodiment 1

[0029] A kind of production technology of 3,5-dichloronitrobenzene, comprises the following steps:

[0030] (1) Diazotization: Add 2000kg of nitrosylsulfuric acid with a mass fraction of 42% into the reactor, cool down to 5°C, add 1000kg of 2,6-dichloro-p-nitroaniline, and control the temperature at 0- 5°C, react for 12h;

[0031] (2) Nitrogen removal: Add 3000kg of isopropanol to the reactor, control the temperature at 10-15°C, and react for 8 hours;

[0032] (3) Hydrolysis: Add 2400kg of desalted water to the reactor, control the temperature at 60°C, and react for 6 hours;

[0033] (4) Stripping: Water vapor is passed into the stripping tower, isopropanol and acetone are recovered by stripping, and isopropanol and acetone are obtained respectively through rectification. After water recovery, desalted water is prepared by R / O membrane separation, which is used in the step (3) During hydrolysis;

[0034] (5) Separation of acid: the bottom liquid after stripping is separated...

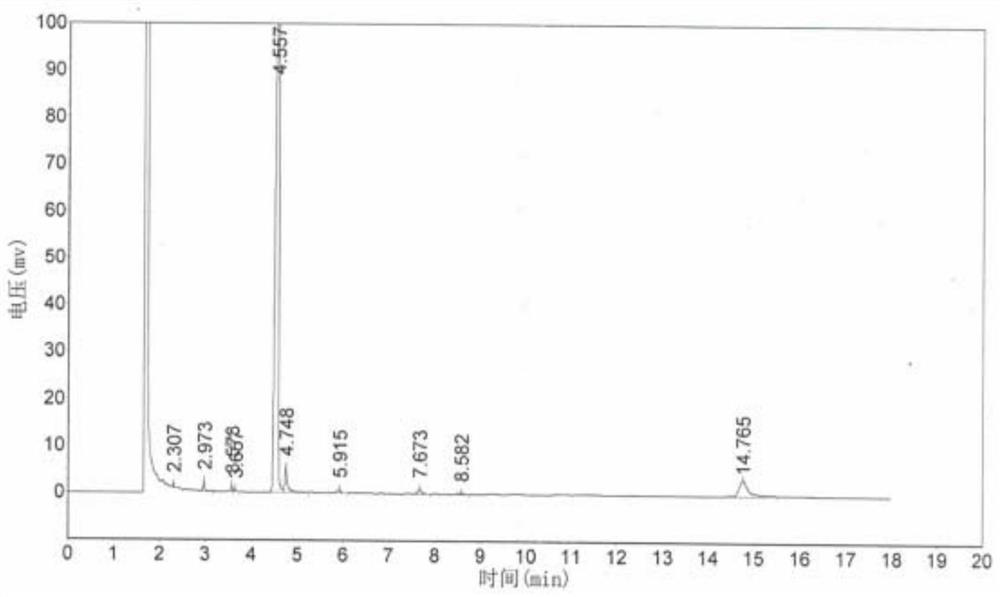

Embodiment 2

[0039] A kind of production technology of 3,5-dichloronitrobenzene, comprises the following steps:

[0040] (1) Diazotization: Add 1600kg of nitrosyl sulfuric acid with a mass fraction of 42% into the reactor, cool down to 5°C, add 1000kg of 2,6-dichloro-p-nitroaniline, and control the temperature at 45°C , reaction 18h;

[0041] (2) Nitrogen removal: add 1600kg of isopropanol to the reactor, control the temperature at 45°C, and react for 9 hours;

[0042] (3) Hydrolysis: Add 2400kg of desalted water to the reactor, control the temperature at 45°C, and react for 9 hours;

[0043] (4) Stripping: Water vapor is passed into the stripping tower, isopropanol and acetone are recovered by stripping, and isopropanol and acetone are obtained respectively through rectification. After water recovery, desalted water is prepared by R / O membrane separation, which is used in the step (3) During hydrolysis;

[0044] (5) Separation of acid: the bottom liquid after stripping is separated int...

Embodiment 3

[0047] A kind of production technology of 3,5-dichloronitrobenzene, comprises the following steps:

[0048] (1) Diazotization: 1700kg of nitrosyl sulfuric acid with a mass fraction of 42% was added to the reactor, the temperature was lowered to 5°C, 1000kg of 2,6-dichloro-p-nitroaniline was added, and the temperature was controlled at 45°C , react for 12h;

[0049] (2) Nitrogen removal: add 1700kg of isopropanol to the reactor, control the temperature at 0°C, and react for 6h;

[0050] (3) Hydrolysis: Add 2500kg of desalted water to the reactor, control the temperature at 0°C, and react for 6 hours;

[0051] (4) Stripping: Water vapor is passed into the stripping tower, isopropanol and acetone are recovered by stripping, and isopropanol and acetone are obtained respectively through rectification. After water recovery, desalted water is prepared by R / O membrane separation, which is used in the step (3) During hydrolysis;

[0052] (5) Separation of acid: the bottom liquid aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com