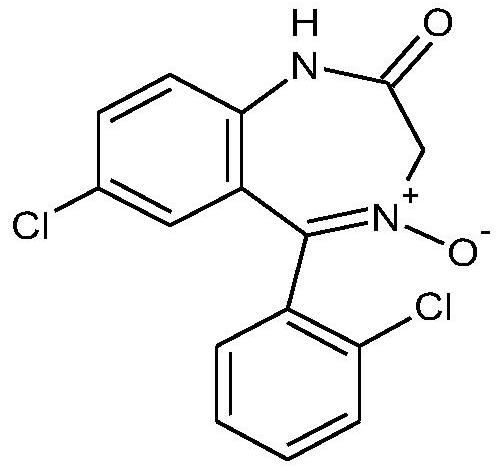

A kind of preparation method of lorazepam intermediate

An intermediate and reaction technology, applied in the direction of organic chemistry, can solve the problems of weakened oxidation, slow reaction rate, and limited reaction temperature, so as to reduce production cost, shorten process cycle, and improve the production site environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

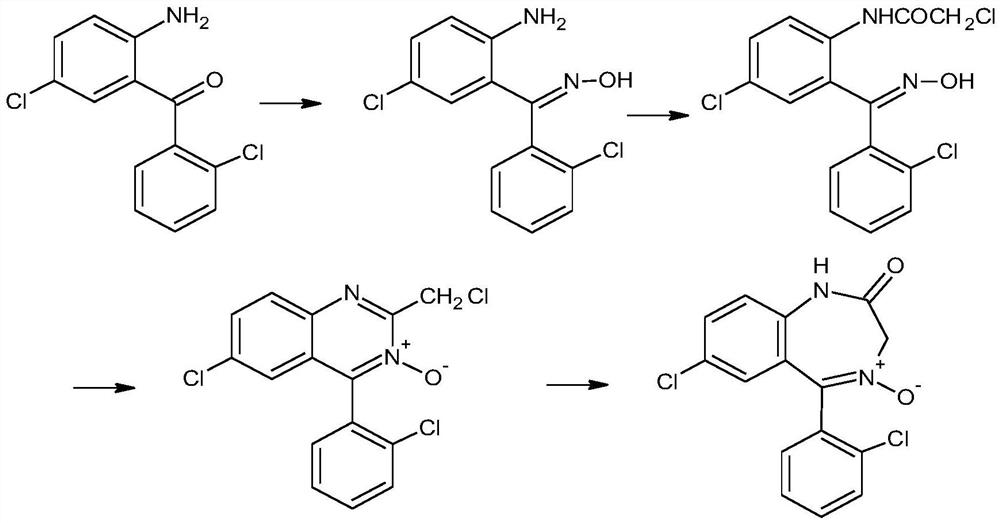

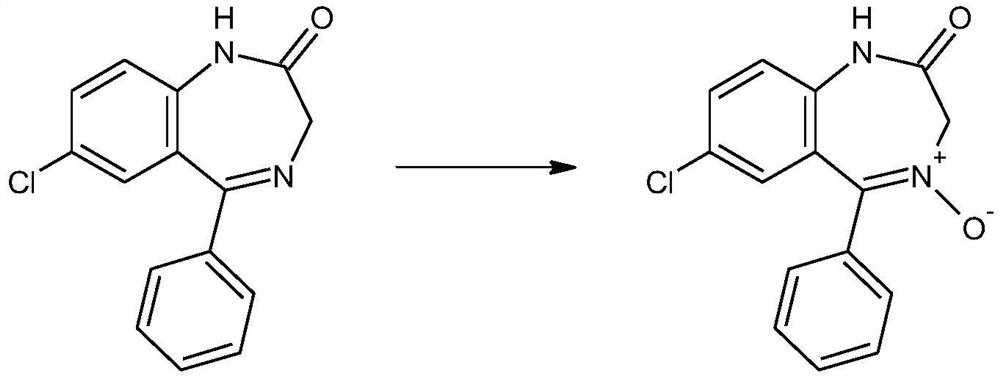

Method used

Image

Examples

Embodiment 1

[0037] Add 30g of 7-chloro-5-(2-chlorophenyl)-1,3-dihydro-2H-1,4-benzodiazepine-2-one and 75ml of dimethylformaldehyde to the reaction flask in turn amide, stir to dissolve and raise the temperature to 40°C, then control the temperature to 40°C to 55°C and add 30 g of hydrogen peroxide with a concentration of 50 wt% dropwise. After the dropwise addition was completed, the reaction was incubated at 55°C to 65°C for 3 hours. After the insulation reaction was completed, the temperature was controlled to be 60°C to 65°C, and 10 g of hydrogen peroxide with a concentration of 50% was added dropwise again. Cool to -5°C, add 30g of water dropwise, continue to stir at 0°C~-5°C for 0.5 hours, stand for 2 hours, filter, wash with water to obtain 7-chloro-2-oxo-5-(2-chloro Phenyl)-1,4-benzodiazepine-4-oxide crude. The crude product was added to a mixed solvent of 90ml of acetone and 30ml of water, beating and refining to obtain 27.2g of 7-chloro-2-oxo-5-(2-chlorophenyl)-1,4-benzodiazepi...

Embodiment 2

[0039] 30g of 7-chloro-5-(2-chlorophenyl)-1,3-dihydro-2H-1,4-benzodiazepine-2-one and 105ml of dimethyl ethyl acetate were added to the reaction flask successively. amide, stir to dissolve and heat up to 40°C, and then control the temperature to 40°C to 55°C and dropwise add 30 g of hydrogen peroxide with a concentration of 50% by mass. After the dropwise addition was completed, the reaction was incubated at 55°C to 65°C for 3 hours. After the insulation reaction is completed, the temperature is controlled to be 60°C to 65°C, and 10 g of hydrogen peroxide with a concentration of 50% by mass is added dropwise again. Cool to -5°C, add 50g of water dropwise, continue to stir at 0°C~-5°C for 0.5 hours, let stand for 2 hours, filter, and wash with water to obtain 7-chloro-2-oxo-5-(2-chloro Phenyl)-1,4-benzodiazepine-4-oxide crude. The crude product was added to a mixed solvent of 60ml of acetone and 15ml of water, beating and refining to obtain 27.5g of 7-chloro-2-oxo-5-(2-chloro...

Embodiment 3

[0041] 30g of 7-chloro-5-(2-chlorophenyl)-1,3-dihydro-2H-1,4-benzodiazepine-2-one and 105ml of dimethyl ethyl acetate were added to the reaction flask successively. amide, stir to dissolve and heat up to 40°C, and then control the temperature to 40°C to 55°C and dropwise add 30 g of hydrogen peroxide with a concentration of 50% by mass. After the dropwise addition was completed, the reaction was incubated at 55°C to 65°C for 3 hours. After the insulation reaction is completed, 15 g of hydrogen peroxide with a mass percentage concentration of 50% is added dropwise again at a temperature of 60°C to 65°C, and the dropwise addition is completed, and the reaction is continued at 60°C to 65°C for 6.5 hours. Cool to -5°C, add 54g of water dropwise, continue to stir at 0°C~-5°C for 0.5 hours, stand for 2 hours, filter, wash with water to obtain 7-chloro-2-oxo-5-(2-chloro Phenyl)-1,4-benzodiazepine-4-oxide crude. The crude product was added to a mixed solvent of 60ml of acetone and 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com