Shading PC material and preparation method thereof

A raw material and acid etching technology, which is applied in the field of light-shielding PC materials and its preparation, can solve problems such as difficult to ensure the mechanical strength of modified materials, and achieve good light-shielding performance and mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

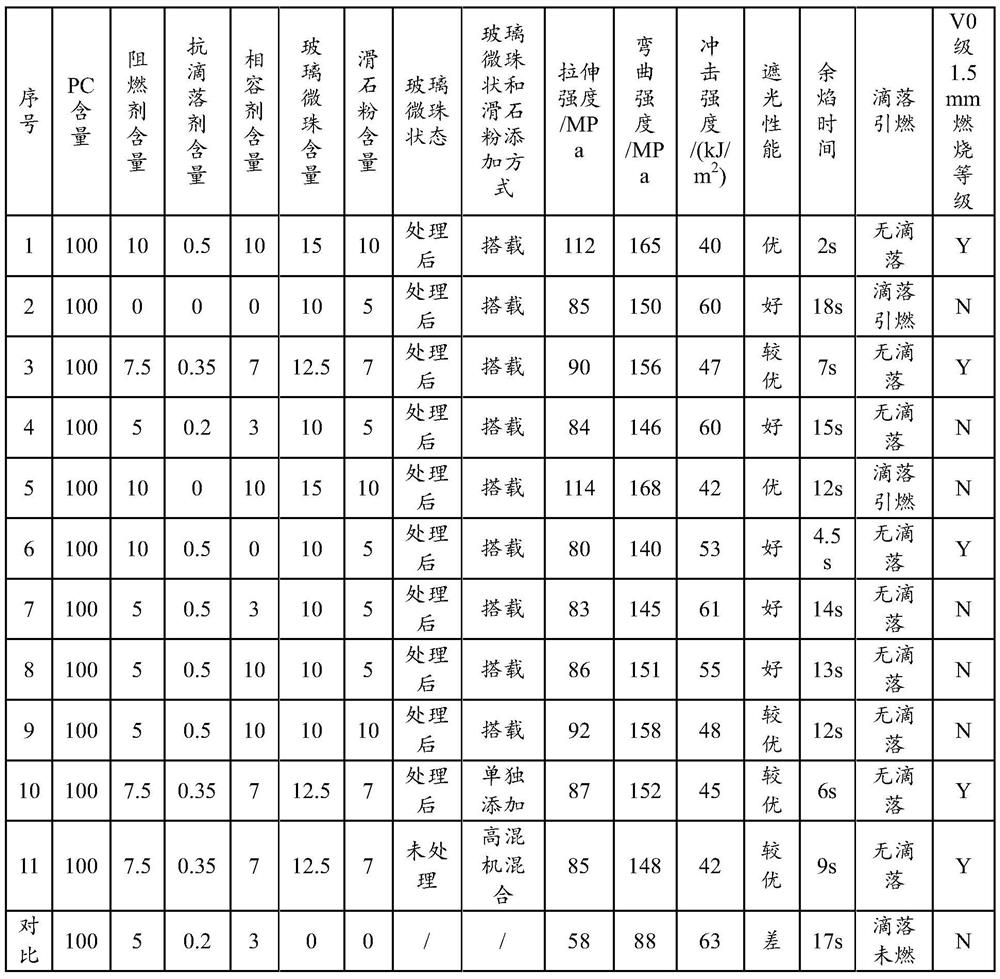

Examples

preparation example Construction

[0033] The preparation method of the acid-etched glass microspheres comprises: acid-etching the hollow glass microspheres with sulfuric acid and phosphate buffer solution.

[0034] The hollow glass microspheres are acid-etched with a mixed solution of sulfuric acid and phosphoric acid buffer solution, wherein the phosphoric acid buffer solution can be NaH with a pH range of 1-5 2 PO 4 or KH 2 PO 4 solution, the sulfuric acid solution can be sulfuric acid with a mass fraction of 95% to 98%, the acid etching time can be 20 to 30s, and the mixed solution of sulfuric acid and phosphoric acid buffer solution is 20-20 to the hollow glass microsphere acid etching temperature. 30°C. Further, the volume ratio of sulfuric acid and phosphate buffer solution may be 10:1-3.

[0035] The particle diameter of the hollow glass microsphere of the present application is 50-100 μm, the wall thickness is 1-4 μm, and the refractive index is 1.9-2.2. It should be noted that after the acid etch...

Embodiment 1

[0058] The hollow glass microspheres were etched in a mixed solution of sulfuric acid and phosphate buffer solution at a temperature of 20°C for 30 seconds, the mass fraction of sulfuric acid was 98%, KH 2 PO 4 The pH of the phosphate buffer solution is 1; after acid etching, the porosity of the surface of the glass microsphere is approximately 15%, and depressions or micropores with a diameter of 3-5 μm are formed. Then filter with a microporous membrane with an average pore size of about 10 μm, and wash with deionized water several times until the pH value of the filtrate is 7 when detected with pH test paper. Dry the cleaned glass microspheres in an oven at approximately 100°C for 2 hours. The volume ratio of sulfuric acid and phosphate buffer solution can be 10:1.

[0059] Make a solution of silane coupling agent A-1100 and stir it evenly. Drop the solution into the aforementioned dried hollow glass microspheres and stir for about 40 minutes to make the coupling agent f...

Embodiment 2

[0065] The hollow glass microspheres were acid-etched in a mixed solution of sulfuric acid and phosphate buffer solution at a temperature of 30°C for 20 seconds, the mass fraction of sulfuric acid was 95%, NaH 2 PO 4 The pH of the phosphate buffer solution is 5; after acid etching, the porosity of the surface of the glass beads is approximately 30%, and a depression or micropore with a diameter of 3-5 μm is formed, and then the microporous membrane with an average pore diameter of approximately 20 μm is used for Filter and wash with deionized water several times until the pH of the filtrate is 7 when detected with pH test paper. Dry the cleaned glass microspheres in an oven at approximately 120°C for 3 hours. The volume ratio of sulfuric acid and phosphate buffer solution can be 10:3.

[0066] Make a solution of silane coupling agent A-1100 and stir it evenly. Drop the solution into the aforementioned dried hollow glass microspheres, and stir for about 60 minutes to make th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com