Drilling device and drilling method

A drilling and drilling fluid technology, applied in the field of petroleum exploration and development, can solve the problems of restricting the large-scale popularization and application of deep strata, short working life of a jet booster device, poor technical application effect, etc., so as to reduce heat exchange and improve heat exchange. Efficiency, effect of reducing trip and trip time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

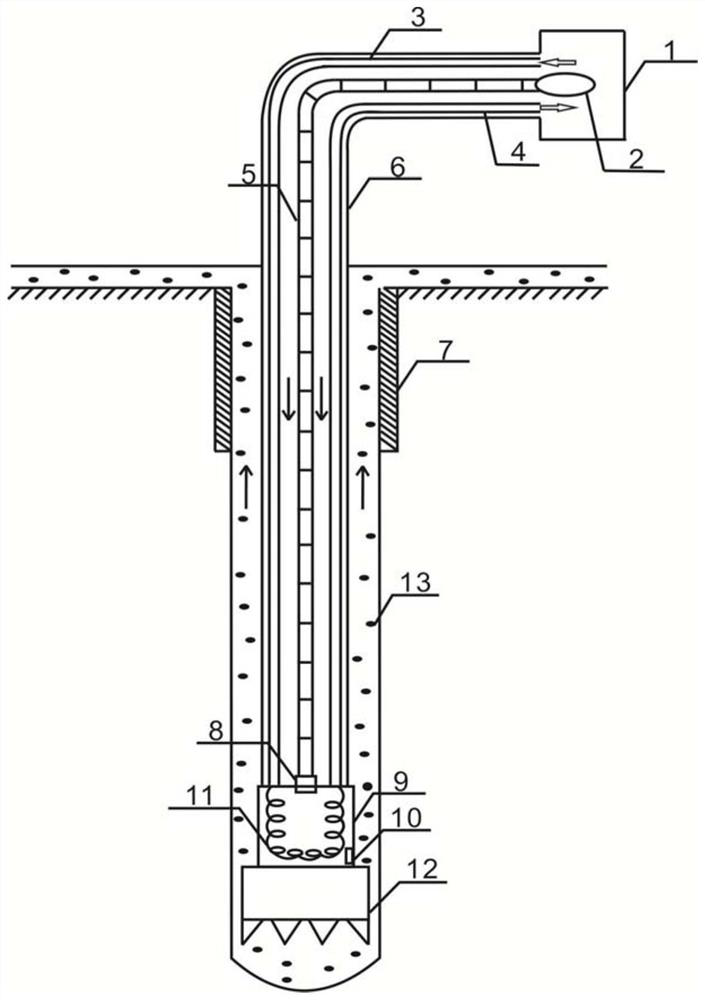

[0038] The present invention will be further described below in conjunction with accompanying drawing.

[0039] The method of thermal rock breaking refers to the use of thermal fluid, radiation flow, particle flow, flame, etc. to generate high temperature and act on the rock surface. Rapid heat transfer inside the rock generates non-uniform stress, and then forms a large number of micro-cracks, eventually leading to rock fragmentation. Research by Potter et al. showed that compared with conventional rock breaking methods, thermal rock breaking methods can save drilling costs better. And the deeper the well, the more cost savings and better economic benefits. This shows that it is more efficient to use the temperature effect to break rocks.

[0040] When the low-temperature fluid contacts the high-temperature rock of the reservoir, the surface temperature of the rock will drop sharply, and the internal particles will shrink to generate tensile stress; when the high-temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com