Garbage incinerator with small NOx pollutants

A garbage incinerator and an incinerator technology are applied to garbage incineration. In the field of flue gas recirculation, it can solve the problems of not giving full play to the effect of flue gas recirculation technology, the difficulty of secondary air to meet the requirements of oxygen regulation, and the lack of in-depth research on flue gas recirculation technology, so as to achieve convenient and effective regulation, save space and cost, and reduce the pressure of denitrification Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

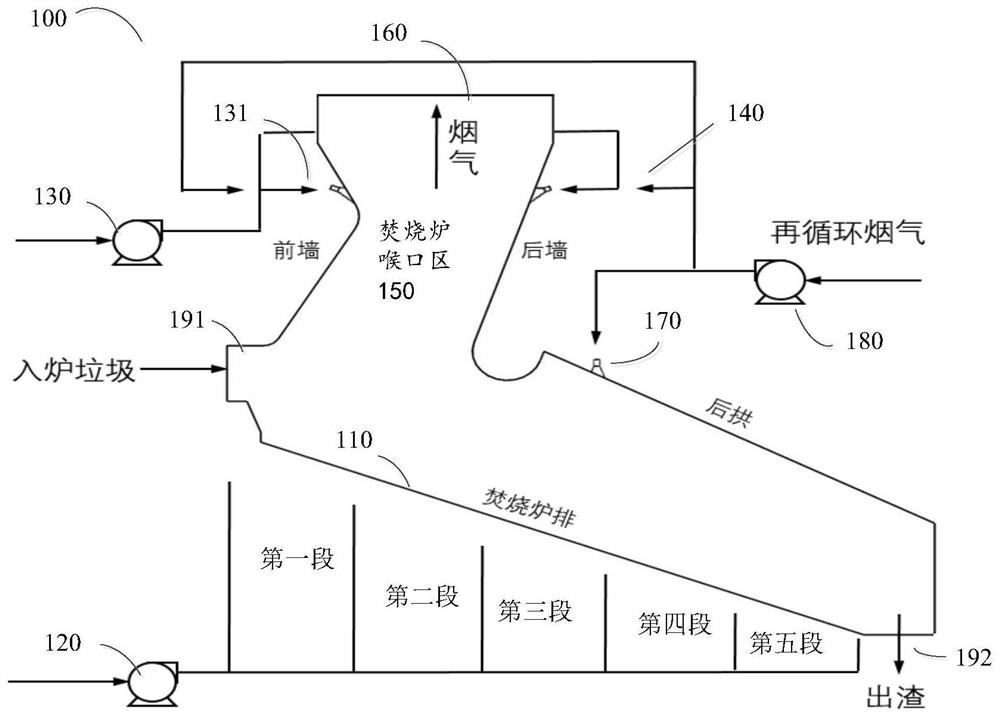

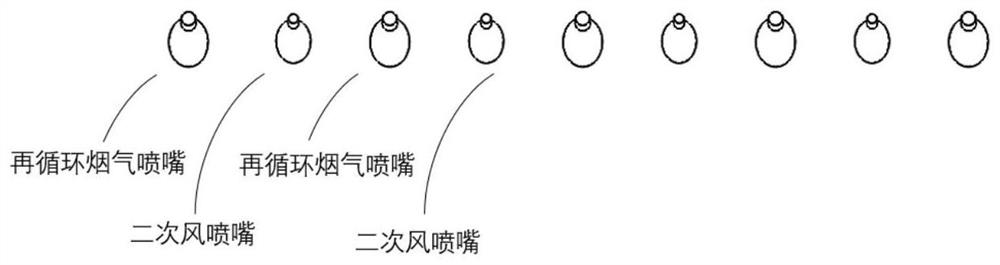

[0028] In order to make the objects, technical solutions, and advantages of the present application more apparent, exemplary embodiments according to the present application will be described in detail below with reference to the accompanying drawings. Apparently, the described embodiments are only some of the embodiments of the present application, rather than all the embodiments of the present application. It should be understood that the present application is not limited by the exemplary embodiments described here. Based on the embodiments of the present application described in the present application, all other embodiments obtained by those skilled in the art without creative efforts shall fall within the protection scope of the present application.

[0029] Incinerator incineration treatment is a widely used waste treatment technology at present, which can realize resource utilization and reduction, but there are problems in pollutant emission control during operation. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com