Three-stage three-section membrane separation system and method for capturing carbon dioxide in flue gas

A membrane separation system and carbon dioxide technology, which are applied in separation methods, use of liquid separation agents, chemical instruments and methods, etc., can solve the problems of unsatisfactory flue gas carbon capture membrane separation systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

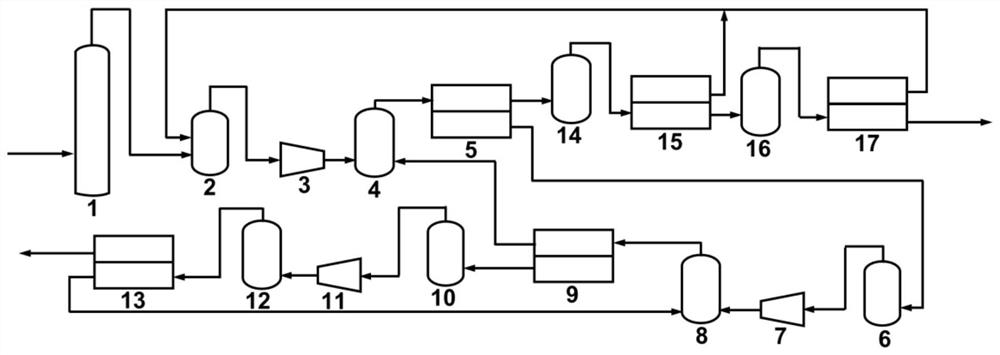

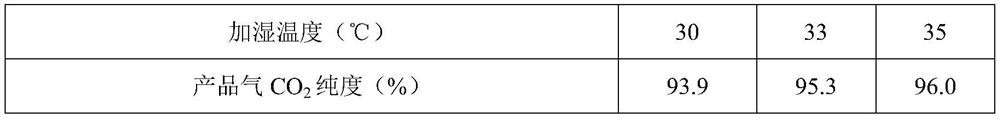

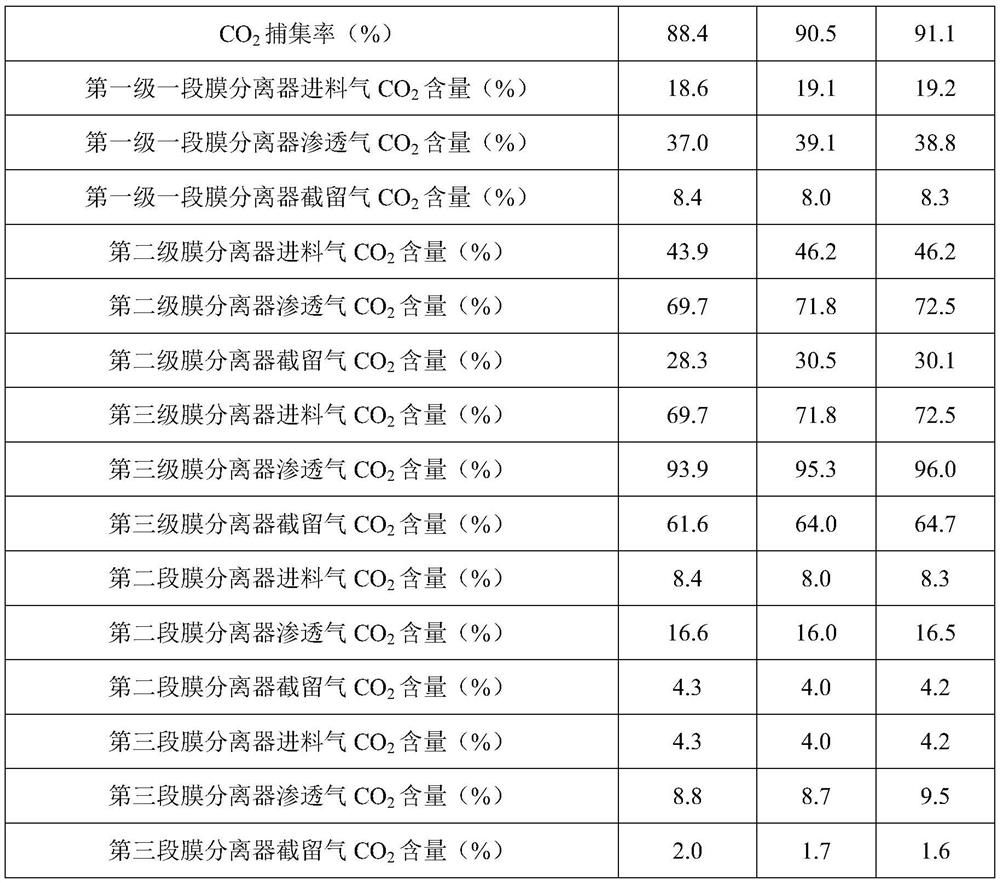

[0044] 1) CO in this embodiment 2 The raw flue gas with a content of 15% (volume content) is transported to the water washing tower (1), and NO is removed through pretreatment in the water washing tower (1) x and SO x and dust and other harmful gases and impurities, enter the first buffer tank (2) together with the permeate gas from the second-stage membrane separator (15) and the third-stage membrane separator (17), and enter the first-stage compression tank (2) after being mixed. Machine (3), compressed to 4.0bar, enters the first mixed humidification tank (4) together with the retained gas of the second-stage membrane separator (9), and enters the first-stage membrane separator (5) after being humidified and fully mixed ;

[0045] 2) The intercepted gas of the first-stage membrane separator (5) enters the fourth mixing humidification tank (14), and enters the second-stage membrane separator (15) after being humidified;

[0046] 3) The trapped gas of the second-stage memb...

Embodiment 2

[0053] 1) CO in this embodiment 2 The raw flue gas with a content of 15% (volume content) is transported to the water washing tower (1), and NO is removed through pretreatment in the water washing tower (1) x and SO x and dust and other harmful gases and impurities, enter the first buffer tank (2) together with the permeate gas from the second-stage membrane separator (15) and the third-stage membrane separator (17), and enter the first-stage compression tank (2) after being mixed. Machine (3), compressed to 4.5bar, enters the first mixed humidification tank (4) together with the retained gas of the second-stage membrane separator (9), and enters the first-stage membrane separator (5) after being humidified and fully mixed ;

[0054] 2) The intercepted gas of the first-stage membrane separator (5) enters the fourth mixing humidification tank (14), and enters the second-stage membrane separator (15) after being humidified;

[0055] 3) The trapped gas of the second-stage memb...

Embodiment 3

[0062] 1) CO in this embodiment 2 The raw flue gas with a content of 15% (volume content) is transported to the water washing tower (1), and NO is removed through pretreatment in the water washing tower (1) x and SO x and dust and other harmful gases and impurities, enter the first buffer tank (2) together with the permeate gas from the second-stage membrane separator (15) and the third-stage membrane separator (17), and enter the first-stage compression tank (2) after being mixed. Machine (3), compressed to 5.0bar, enters the first mixed humidification tank (4) together with the retained gas of the second-stage membrane separator (9), and enters the first-stage membrane separator (5) after being humidified and fully mixed ;

[0063] 2) The intercepted gas of the first-stage membrane separator (5) enters the fourth mixing humidification tank (14), and enters the second-stage membrane separator (15) after being humidified;

[0064] 3) The trapped gas of the second-stage memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com