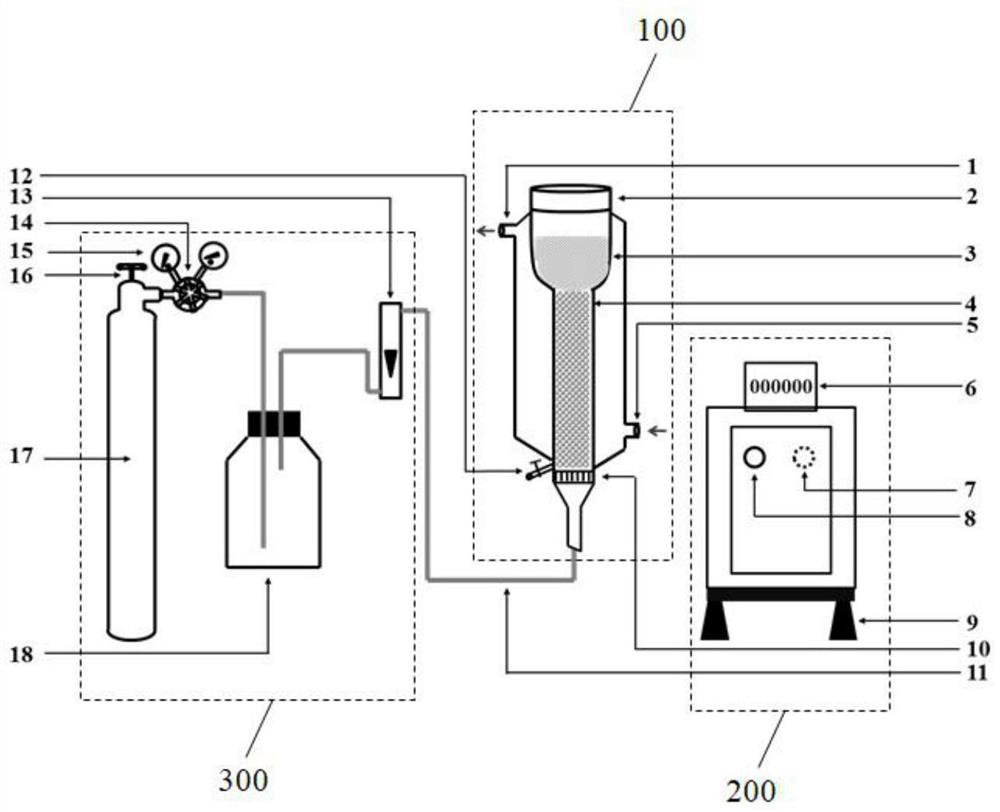

Extraction separation device and extraction separation method for lithium isotopes

A lithium isotope and separation method technology, applied in the field of lithium isotope separation, can solve the problems of complex operation, low extraction separation and enrichment effect, extraction agent dissolution and entrainment loss, etc., to achieve improved cycle performance, good separation and enrichment effect, The effect of increasing abundance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The liquid gun was removed from the liquid gun (0.2 mol / L 4-Br-B15C5, the ionic liquid was 1-butyl-3-imidazole double trifluoromethane sulfonic salt ([BIM] [NTF 2 ]), Benzyl ether is an organic solvent, a volume ratio of ionic liquid and benzoether having a volume ratio of 1: 19) and 8 ml of water phase (2 mol / L iodide) to the reaction vessel, the experimental temperature is 15 ° C, access The inert gas is nitrogen and the venting flow rate is 20 ml / min, and the ventilation time is 60 min. After the reaction is completed, the extraction after the extraction is transferred to a new container, and 3 ml of 1 mol / L of HCl solution was subjected to substrate washing, and the reverse washing step was repeated. The anti-extract can reach 99%. Water samples for lithium isotope rich test, measure δ 7 Li (‰) = - 27.47 ‰, ie after separation and enrichment 6 Li's abundance reached 7.831%.

Embodiment 2

[0055] The liquid gun was removed from the liquid gun (0.2 mol / L 4-Br-B15C5, the ionic liquid was 1-butyl-3-imidazole double trifluoromethane sulfonic salt ([BIM] [NTF 2 ]), Benzyl ether is an organic solvent, a volume ratio of ionic liquid and benzoether having a volume ratio of 1: 15) and 6 mL of aqueous phase (2 mol / L lithium chloride) to the reaction vessel, the experimental temperature is 15 ° C, access Inert gas nitrogen, with a ventilation flow rate of 15 ml / min, and a ventilation time is 80 min. After the reaction is completed, the extraction after the extraction is transferred to a new container, and 3 ml of 1 mol / L of HCl solution was subjected to substrate washing, and the reverse washing step was repeated. The anti-extract can reach 99%. Water samples for lithium isotope rich test, measure δ 7 Li (‰) = - 21.88 ‰, ie after a single separation 6 Li's abundance reached 7.790%.

Embodiment 3

[0057] Milled guns were removed from the organic phase (0.3 mol / L 4-Br-B15C5, the ionic liquid was 1-butyl-3-imidazole double trifluoromethane sulfonamide salt ([BIM] [NTF 2 ]), Benzyl ether is an organic solvent, a volume ratio of ionic liquid and benzoether having a volume ratio of 1: 9) and 6 mL (4 mol / L iodide) to the reaction vessel, the experimental temperature is 5 ° C, access The inert gas is nitrogen, with a ventilation flow rate of 20 ml / min, and the ventilation time is 80 min. After completion of the reaction, the extracted organic phase was transferred to a new container, and 3 ml of 2 mol / L of HCl solution was subjected to subtracking, repeated reverse washing step 3 times, and the anti-extract can reach 99%. Water samples for lithium isotope rich test, measure δ 7 Li (‰) = - 37.45 ‰, ie after a single separation 6 Li's abundance reached 7.906%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com