Novel angle-adjustable casting cutting multifunctional robot

A multi-functional, robotic technology, applied in shearing devices, maintenance and safety accessories, accessories of shearing machines, etc., can solve problems such as easy deflection, single cutting angle, scrapped castings, etc., to avoid operation errors, cutting Accurate operation and the effect of improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the examples.

[0030] The following examples are used to illustrate the present invention, but cannot be used to limit the protection scope of the present invention. The conditions in the embodiment can be further adjusted according to the specific conditions, and the simple improvement of the method of the present invention under the premise of the concept of the present invention belongs to the protection scope of the present invention.

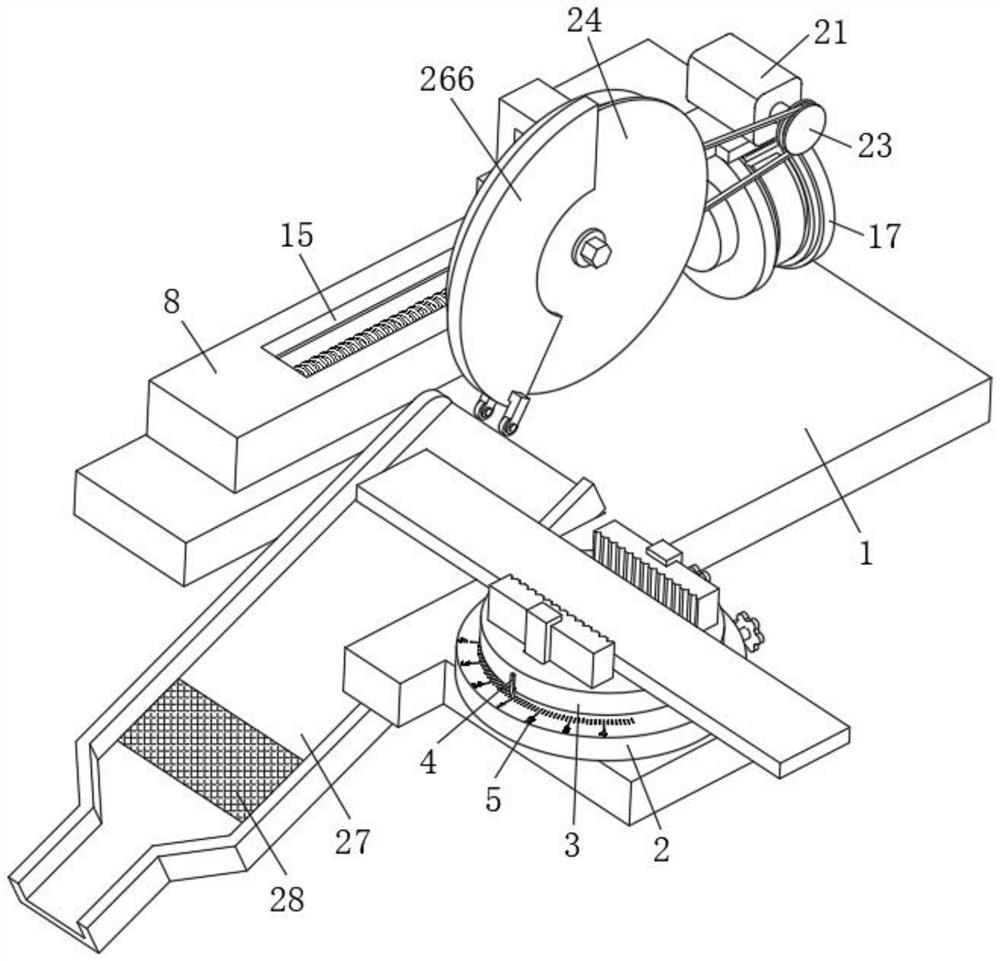

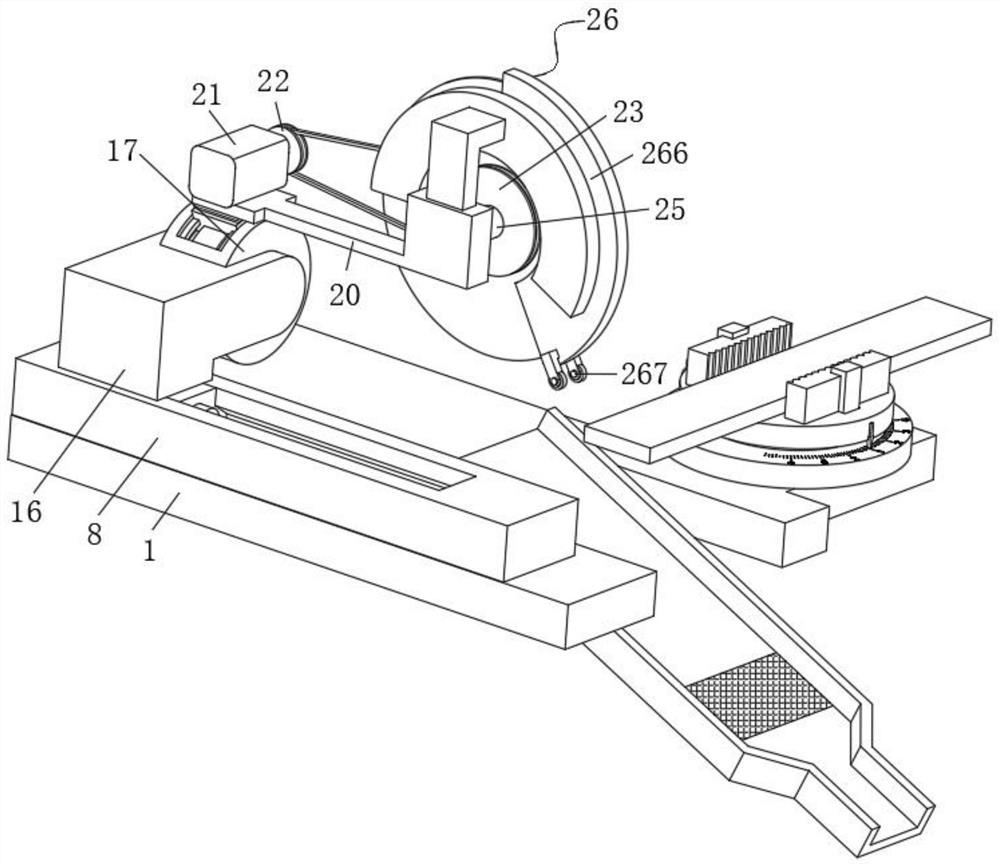

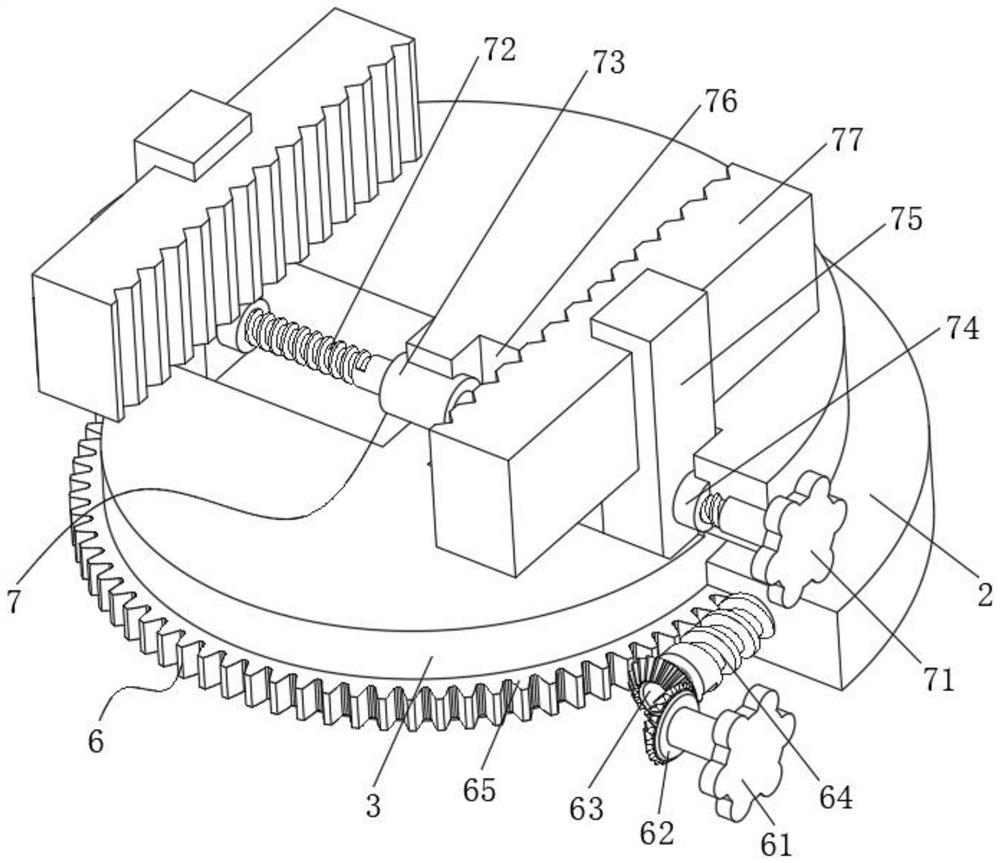

[0031] see Figure 1-6 , the present invention provides a novel angle-adjustable casting cutting multifunctional robot, comprising a bottom plate 1, a fixed seat 2 is fixedly connected to the bottom plate 1, and a rotating seat 3 is rotatably connected to the fixed seat 2, and the upper surface of the fixed seat 2 is close to the edge An angle scale 5 is provided at the position of the rotating seat 3, and a pointer 4 is fixed at the position corresponding to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com