Spatial intersecting curve weld joint structure modeling method based on line structured light vision

A technology of linear structured light and structural modeling, which is applied to the characteristics of welding rods, welding equipment, welding accessories, etc., can solve the problems that cannot meet the modeling requirements of curve welds, the model does not have universality, and lacks the structural characteristics of workpieces around the weld. detection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The technical solution of the present invention will be further described below according to the drawings and specific embodiments.

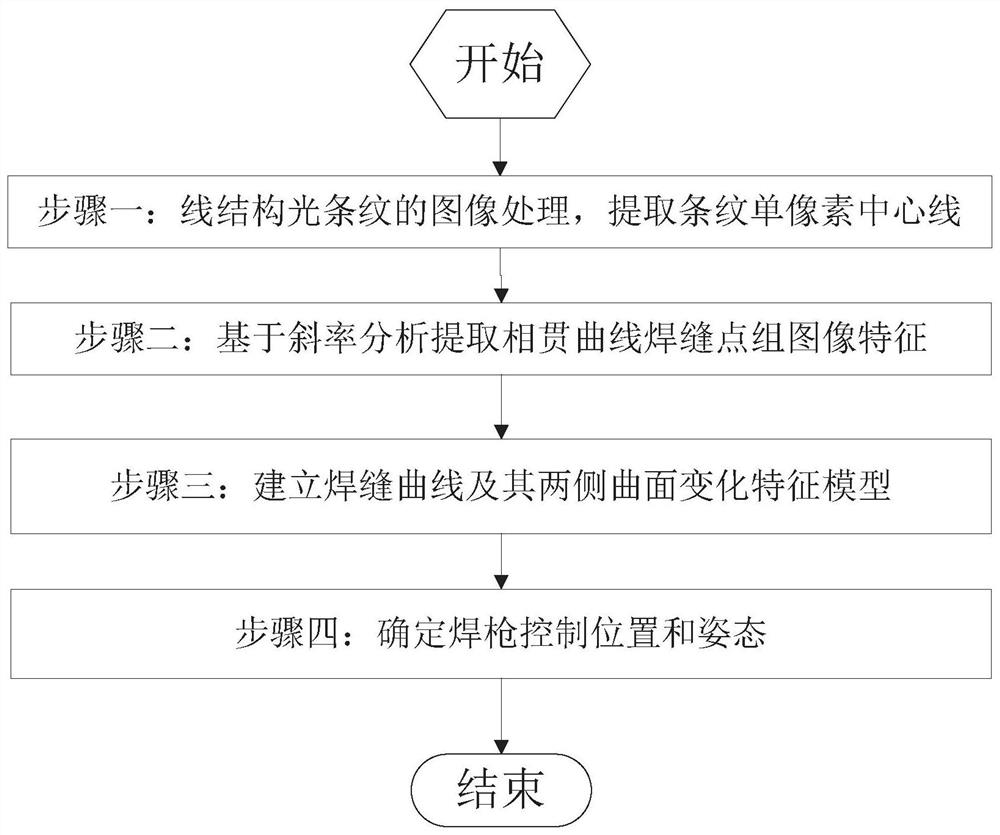

[0078] A method for modeling spatially intersecting curve weld structures based on line structured light vision, comprising the following steps:

[0079] according to figure 1 The overall flow chart shown, the implementation steps are as follows:

[0080] Step 1: Process the structured light fringe image of the weld interface line, and extract the single-pixel centerline of the fringe.

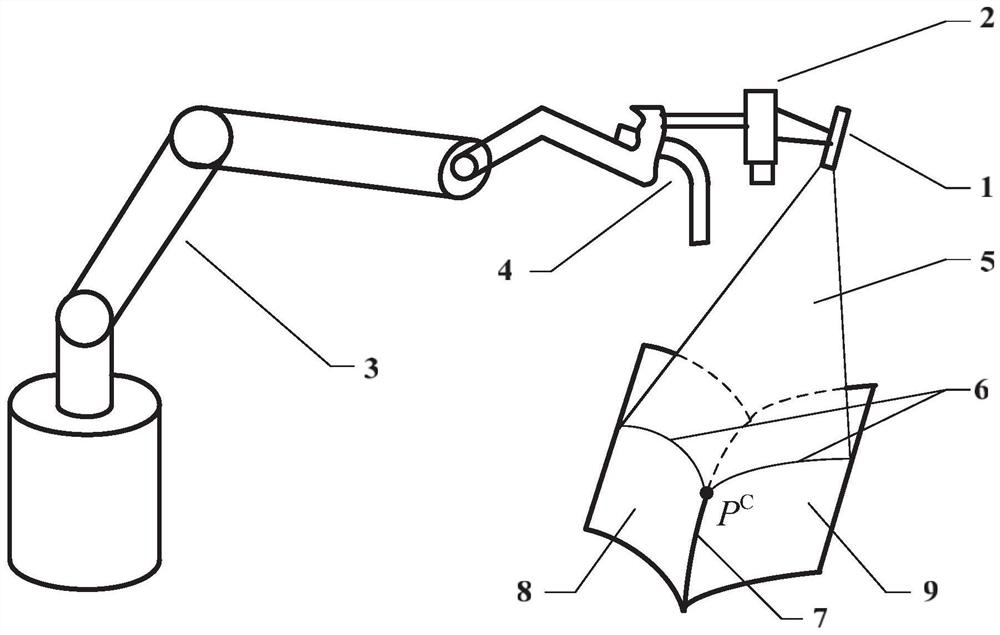

[0081] as attached figure 2 As shown, the line structured light laser 1 and the industrial camera 2 are fixedly installed on the end of the mechanical arm 3 to form a fixed relative position with the welding torch 4 . The movement of the mechanical arm 3 is controlled so that the line structured light emitted by the line structured light laser 1 is projected onto the intersecting curve weld interface, and the structured light plane 5 forms line struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com