Multi-station intelligent welding equipment for motor stator of new energy automobile

A technology for new energy vehicles and motor stators, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve problems such as inability to guarantee product quality, scattered production layout, and low degree of automation, so as to ensure product welding effect and save energy. Space resources, the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

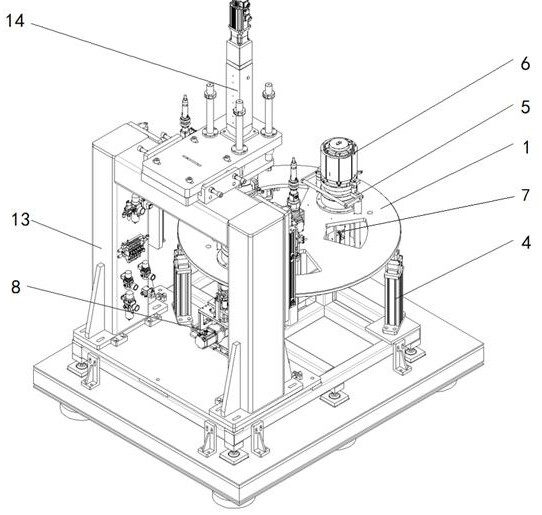

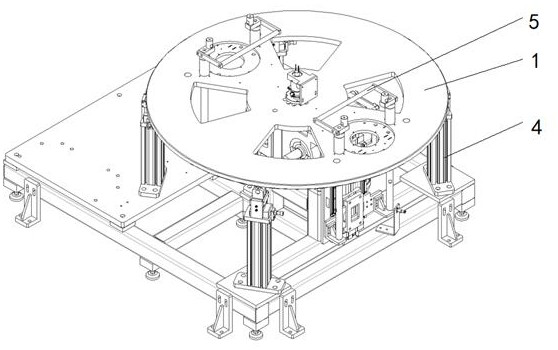

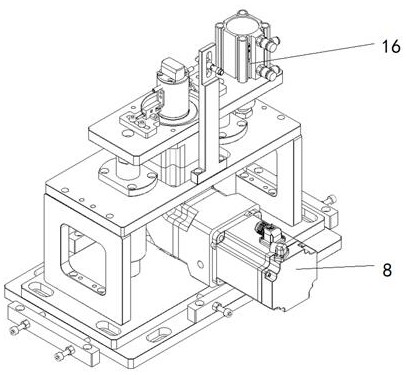

[0030] Such as Figure 1~Figure 5 As shown, the present invention discloses a multi-station intelligent welding equipment for automatic welding and processing of stator products in new energy vehicle motors and permanent magnet synchronous motors. The specific scheme is as follows.

[0031] A new energy automobile motor stator multi-station intelligent welding equipment is set on the equipment platform as a whole, including a set of turntable components and a set of welding components. The turntable assembly includes a product support turntable 1 for carrying products. The product support turntable 1 is provided with a preparation station and a welding station. Through the horizontal rotation of the product support turntable 1 1. The product reciprocates between the preparation station and the welding station. The installation position of the welding assembly corresponds to the position of the welding station, and the welding assembly includes a product pressure plate 2 for p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com