Yellowing-resistant and bottom-impermeable polymer engineering membrane

A polymer, yellowing-resistant technology, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, layered products, etc. Achieve the effect of no color difference, good flatness, and few crystal points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

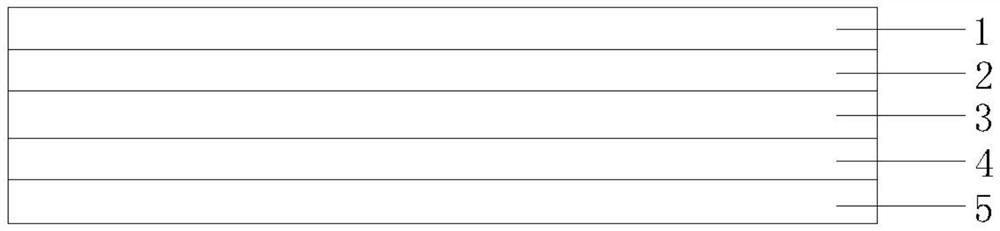

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0015] Such as figure 1 A kind of anti-yellowing and bottom-proof polymer engineering film as shown, comprising PET surface layer 1, glue layer 2, outer milky white masterbatch layer 3, inner milky white masterbatch layer 4 and bottom film 5; said outer milky white masterbatch The layer includes LDPE and milky white masterbatch, the inner milky white masterbatch layer includes LLDPE and milky white masterbatch, and the glue layer is composed of the following materials in parts by weight: 90 parts of acrylic glue, 8-12 parts of tackifying resin, curing agent 0.1-0.5 parts, 10 parts of water-based polyurethane resin, 1-5 parts of modified nano silicon dioxide, and 70-90 parts of solvent, wherein the solvent is selected from ethyl acetate or toluene. The weight ratio of LDPE and milky white masterbatch in the outer milky white masterbatch layer is 1:1. The wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com