Magnetic suspension fluid conveying device

A technology of fluid transportation and magnetic levitation, which is applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc. It can solve the problems of reducing the type of material transportation, large energy loss, concentric movement of pipelines, etc., and achieves the reduction of complex process, Reduce transportation costs and solve the effect of material blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with accompanying drawing:

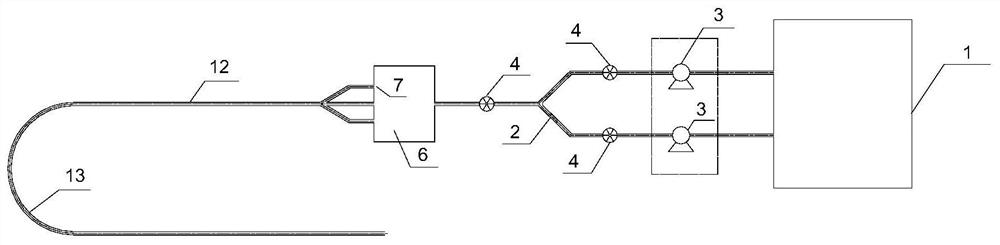

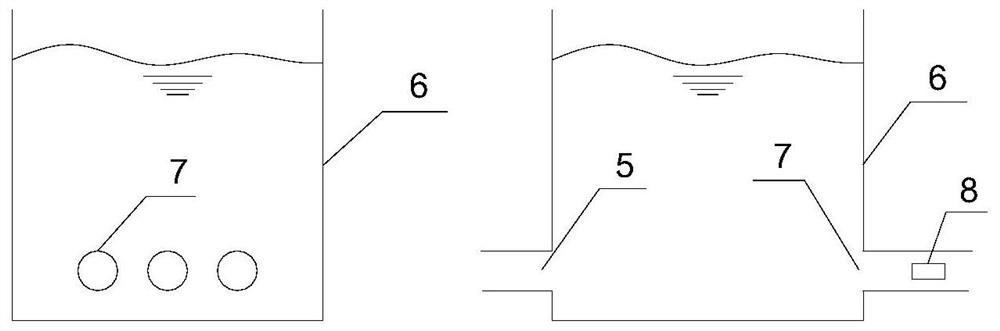

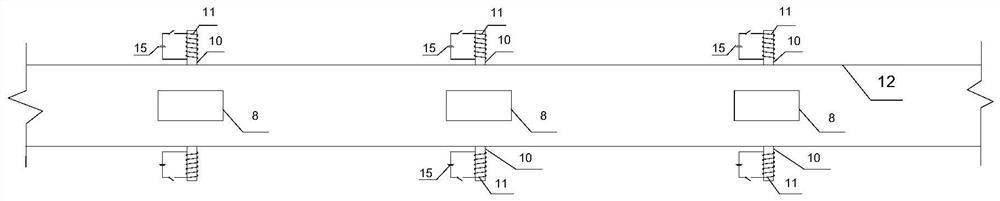

[0050] Such as Figure 1-11 As shown: the present invention includes an upstream reservoir 1, a pumping pipeline 2, a clear water centrifugal pump unit 3, a fully automatic valve 4, an open water tank 6, a capsule inlet 7, a straight pipeline 12 and a curved pipeline 13, and the upstream reservoir 1 The outlet of the clean water centrifugal pump unit 3 is connected to the inlet of the clean water centrifugal pump unit 3, and the multiple outlets of the clean water centrifugal pump unit 3 are connected to the inlets of the multiple automatic valves 4, and the outlets of the multiple automatic valves 4 pass through the The pumping pipeline 2 is connected to the inlet of one of the fully automatic valves 4, the outlet of the fully automatic valve 4 is connected to the inlet of the open water tank 6, and the outlet of the open water tank 6 is provided with a plurality of the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com