Method for efficiently separating cyclohexanone and removing impurities in cyclohexanol

A technology of cyclohexanol and cyclohexanone, applied in the field of preparation of cyclohexanone, can solve the problems of high energy consumption, removal and consumption without optimized engineering design, and achieve the advantages of reducing equipment investment, reducing floor space and eliminating accumulation phenomenon. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

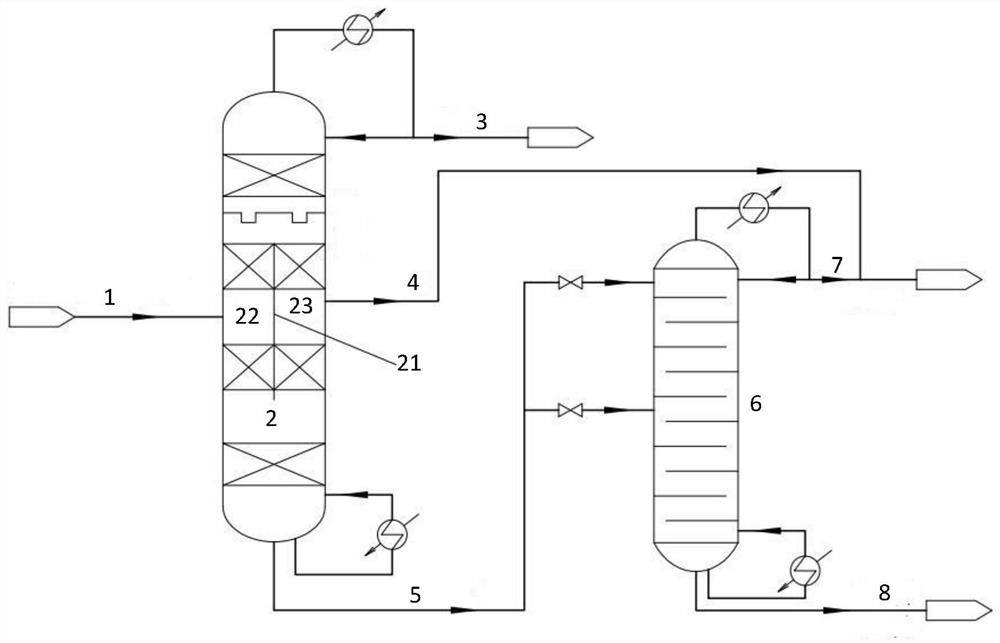

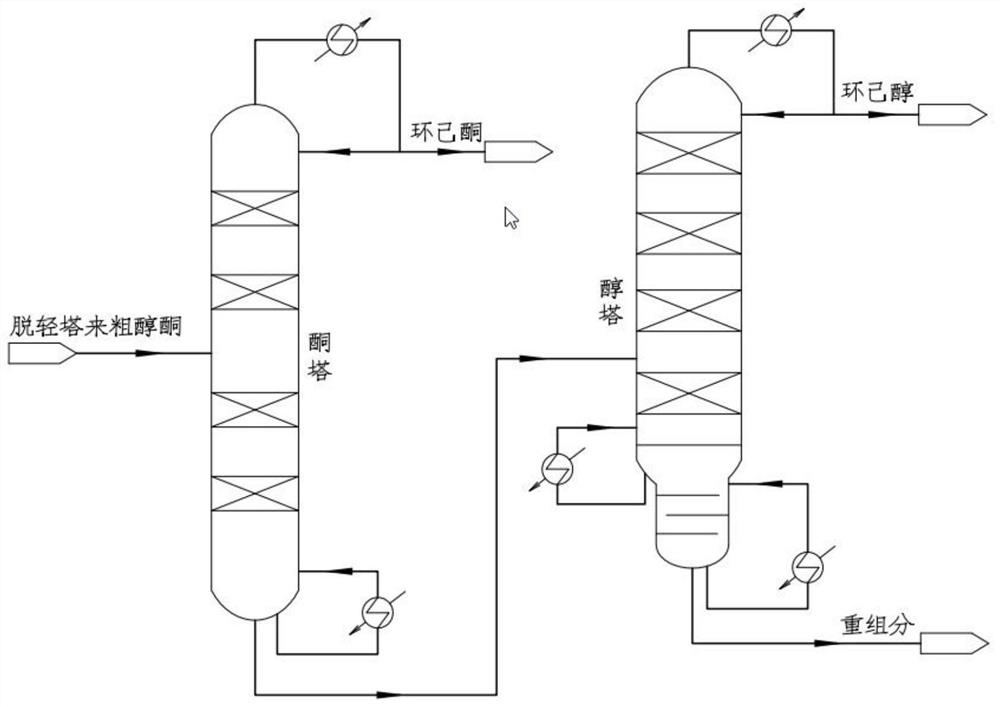

[0037] The separation of alcohol and ketone in the cyclohexanone plant with an annual output of 150,000 tons of cyclohexane alkoxylation adopts the high-efficiency separation and impurity removal process flow of the present invention, the next-door tower adopts structured packing, and the impurity removal tower adopts a plate tower, such as figure 1 shown.

[0038] The crude alcohol and ketone from the bottom of the light removal tower enters the feed side of the dividing wall tower, the feed amount is 40t / h, and the feed composition is 42w% of cyclohexanol, 51.7w% of cyclohexanone, 5.1w% of intermediate components, and 0.3 w%. The operating pressure at the top of the next wall tower is 3KPaA, and the operating temperature is 55°C. The gas phase at the top of the tower is cooled by the condenser, and part of it is refluxed to the top of the tower. The reflux ratio at the top of the tower is 3.5. Score ≥ 99.95%; the internal reflux ratio of the liquid collector tank above the ...

Embodiment 2

[0043] The separation of alcohol and ketone in the cyclohexanone plant with an annual output of 150,000 tons of cyclohexane alkoxylation adopts the high-efficiency separation and impurity removal process flow of the present invention, the next-door tower adopts structured packing, and the impurity removal tower adopts a plate tower, such as figure 1 shown.

[0044] The crude alcohol and ketone from the bottom of the light removal tower enters the feed side of the dividing wall tower. The feed amount is 44t / h. The feed composition is 44.34w% of cyclohexanol, 51.20w% of cyclohexanone, 3.5w% of intermediate components, and 0.9w%. The operating pressure at the top of the next wall tower is 4KPaA, and the operating temperature is 56°C. The gas phase at the top of the tower is cooled by the condenser, and part of it is refluxed to the top of the tower. The reflux ratio at the top of the tower is 3.8. Score ≥ 99.96%; the internal reflux ratio of the liquid collecting tray above the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com