Intrinsic black polyurethane with near-infrared photothermal effect and its preparation and application

A near-infrared light and thermal effect technology, applied in the field of functional polymer materials, can solve the problems of cumbersome preparation process, and achieve the effects of excellent mechanical properties, fast and efficient welding, and triggering dynamic exchange.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The raw material of the intrinsic black polyurethane in this embodiment includes: 35.4 parts by mass of THDI, 14.6 parts by mass of p-benzoquinonedioxime, and no polyurethane catalyst is added.

[0030] The steps of the preparation method of this embodiment include:

[0031] After mixing 35.4 parts by mass of THDI and 14.6 parts by mass of p-benzoquinone dioxime, no catalyst is added, stirred evenly by hand with a glass rod, then added to the internal mixer, and the temperature of the internal mixer is increased to 80°C for internal mixing After 6 hours, a brown powder material was obtained, and the powder material was hot-pressed in a flat vulcanizer under the conditions of 140° C., 5 MPa, and 45 min, to obtain a uniform intrinsic black film.

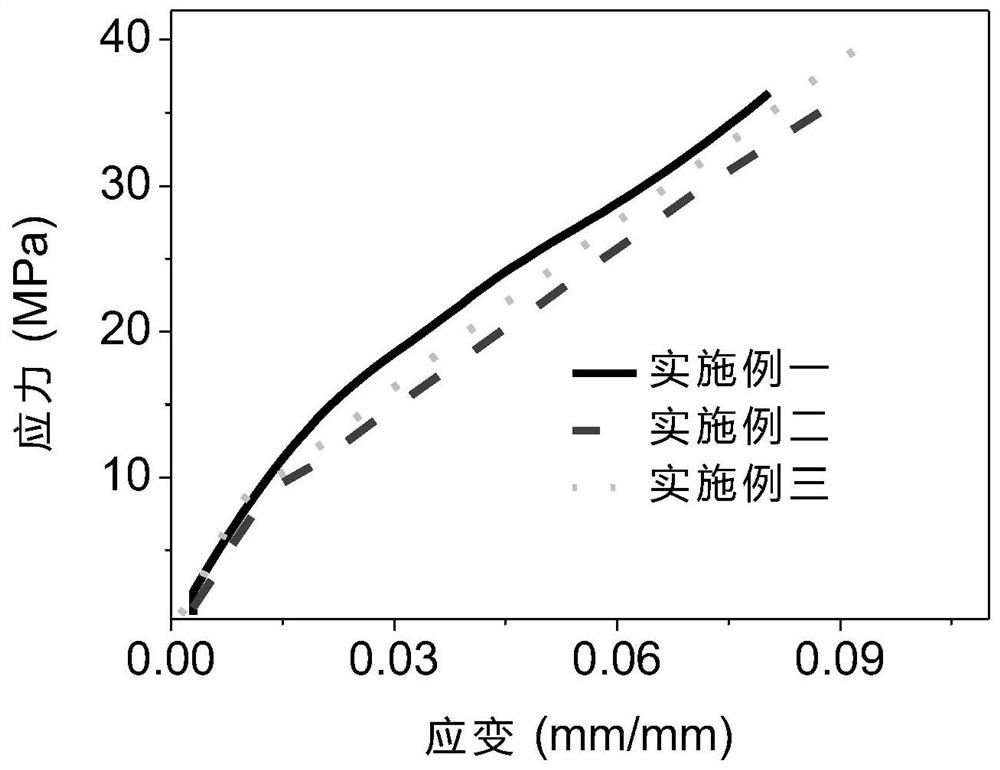

[0032] Its stress-strain curve is shown in figure 1 shown. It is in glass state at room temperature, its modulus can reach about 1GPa, and its fracture strength can reach 40MPa. See figure 1 and Table 1.

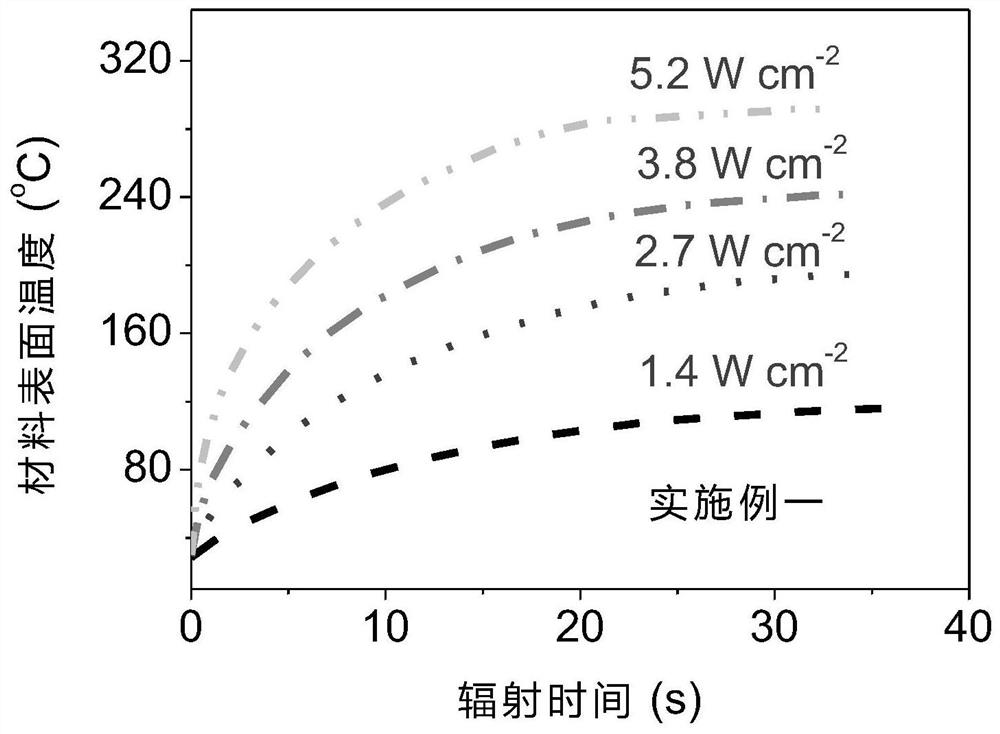

[0033] The film c...

Embodiment 2

[0037] The intrinsically black polyurethane of this embodiment includes raw materials: 35.4 parts by mass of THDI, 0.5 parts by mass of DBTDL, and 14.6 parts by mass of p-benzoquinonedioxime.

[0038]The steps of the preparation method in this example include: mixing 35.4 parts by mass of THDI and 0.5 parts by mass of DBTDL, stirring with a glass rod for 5 minutes, adding 14.6 parts by mass of p-benzoquinonedioxime, and continuing to manually stir with a glass rod Finally, add it to the internal mixer, increase the temperature of the internal mixer to 70°C, and carry out internal mixing for 7 hours to obtain a brown powder material; the powder material is hot-pressed in a flat vulcanizer, and the hot-pressing condition is 150°C, 4.5MPa, After 40 min, a uniform intrinsic black film was obtained. Its stress-strain curve is shown in figure 1 shown.

[0039] The film can be applied in the field of thermosetting resin photowelding and shape memory recovery, and has a significant ...

Embodiment 3

[0041] The intrinsic black polyurethane of the present embodiment has the same raw material components as in the second embodiment.

[0042] The steps of the preparation method in this example include: mixing 35.4 parts by mass of THDI and 0.5 parts by mass of U600, stirring with a glass rod for 5 minutes, adding 14.6 parts by mass of p-benzoquinonedioxime, and continuing to manually stir with a glass rod Finally, add it to the internal mixer, increase the temperature of the internal mixer to 60°C, and carry out internal mixing for 5 hours; obtain a brown powder material; hot press the powder material in a flat vulcanizer, and the hot pressing condition is 160°C, 6MPa, 35min A uniform intrinsically black film was obtained. Its stress-strain curve is shown in figure 1 shown.

[0043] The film can be applied in the field of thermosetting resin photowelding and shape memory recovery, and has a significant photothermal effect under near-infrared light irradiation. The large amo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com