Composite material reflector forming and assembling method

A technology of composite materials and assembly methods, which is applied to other household appliances, household appliances, household components, etc., to achieve the effects of ensuring accuracy, reducing manufacturing costs, and ensuring surface quality and surface accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

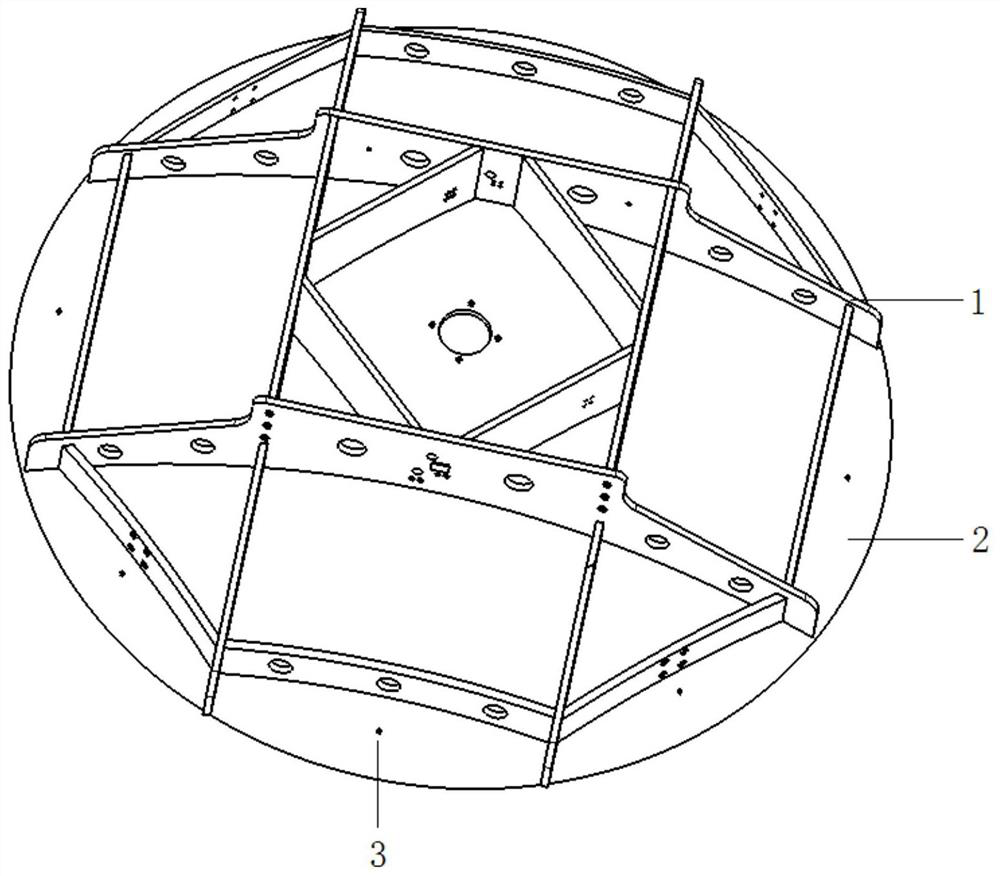

[0027] Implementation example 1: a satellite main reflector

[0028] Main materials: carbon fiber unidirectional belt prepreg M40J, adhesive film REDUX 312UL, porous aluminum honeycomb core BC1.8-3 / 8P-15, foam adhesive FM410-1, structural adhesive EC2216B / A, dry glass cloth EW100, adhesive AO-3

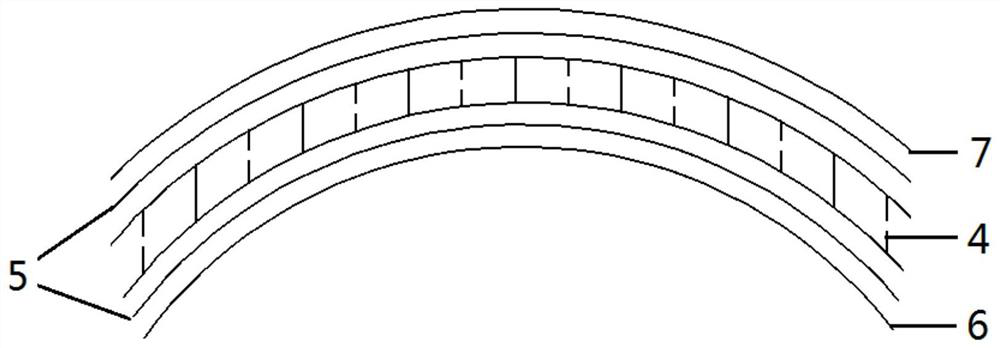

[0029] 1) Upper and lower skin forming

[0030] Taking the forming mold of the reflective surface 1 as the model body, a composite material dummy for forming the upper skin 7 is manufactured using carbon fiber prepreg and NOMEX honeycomb core, and then the lower skin 6 is laid on the molding mold and the dummy respectively ( working surface) and upper skin 7 prepregs, the prepregs are paved with a 50mm narrow strip, and the narrow strips are butt spliced. The number of paving layers is 4 layers, and the angle is [0° / +45 ° / -45° / 90°] symmetrical. During the paving process, it is required that each layer must be vacuum compacted. After the last layer of the lower skin is paved, the ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com