Method for controlling aging of ultrafiltration membrane by strengthening chemical cleaning through micro-nano bubble technology

A micro-nano bubble, chemical cleaning technology, applied in chemical instruments and methods, special treatment targets, water/sewage treatment, etc., can solve the problem of high cleaning costs for a single micro-nano bubble, achieve efficient control of membrane aging process, and prolong membrane use. Longevity and the effect of reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

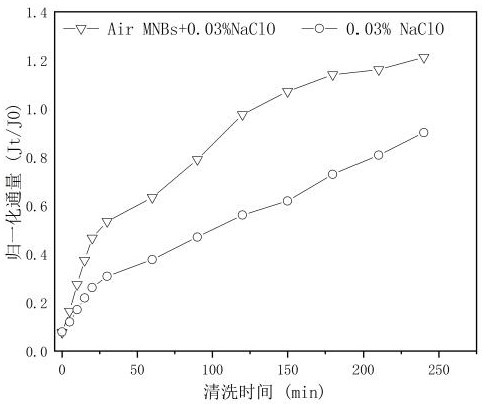

specific example 1

[0026] Process conditions:

[0027] Contaminated film: PVDF ultrafiltration membrane contaminated with anionic polyacrylamide;

[0028] Washing method: micro-nano-bubble + drug solution is soaked;

[0029] Cleaning temperature: 10 ° C;

[0030] Cleaning time: Each step is different;

[0031] Cleaning fluid formulation: Choose pure water as a solvent;

[0032] Suitable exposure to sodium hypochlorite chemical cleaning liquid: sodium hypochlorite is 0.03%, and the solution pH = 10 in hydrochloric acid is adjusted, and the soaking time is 120 min;

[0033] Micronine bubble technology: Air supply is gas source, control pressure at 0.4-0.5MPa, gas flow is 350-400 ml / min, the liquid environment is 20 ° C, the micro-nano bubble size range 850 nm-10 μm, the micronine bubble interface Zeta potential is -55mV;

[0034] Cleaning steps:

[0035] (1) Pure water spraying and backwashing of the contaminated film, the reversible contamination of the film surface is removed, and the flushing tim...

specific example 2

[0040] Process conditions:

[0041] Contaminated film: Ultrafiltration process Treatment of PVDF contaminated film in waste water;

[0042] Washing method: micro-nano-bubble + drug solution is soaked;

[0043] Cleaning temperature: 10 ° C;

[0044] Cleaning time: Each step is different;

[0045] Cleaning fluid formulation: Choose pure water as a solvent;

[0046] Suitable exposure of sodium hypochlorite chemical cleaning liquid: sodium hypochlorite is 0.01%, and the solution pH = 10 in hydrochloric acid is adjusted, and the soaking time is 30 min;

[0047] Dodecyl trimethyl ammonium chloride cleaning liquid: molar concentration is 2.0 cmc (CMC, the critical micellar concentration of the surfactant), pH = 7, soaking time is 40 min;

[0048] Micronine bubble technology: Take nitrogen as a gas source, control pressure at 0.4-0.5 MPa, gas flow is 450-500 mL / min, and the liquid environment is 10 ° C;

[0049] Cleaning steps:

[0050] (1) Pure water spraying and backwashing of the con...

specific example 3

[0057] Process conditions:

[0058] Contaminated film: contaminated film in the ultrafiltration process.

[0059] Washing method: micro-nano-bubble + drug solution is soaked;

[0060] Cleaning temperature: 10 ° C;

[0061] Cleaning time: Each step is different;

[0062] Cleaning fluid formulation: Choose pure water as a solvent;

[0063] Disodium ethylenediamine tetracetate cleaning liquid: concentration of 3.5 mmol / L, sodium bicarbonate regulates pH = 7, soaking time is 20 min;

[0064] Dodecyl trimethyl ammonium chloride cleaning liquid: molar concentration is 1.0 cmc, pH = 7, soaking time is 30 min;

[0065] Micronine bubble technology: Take pure oxygen as a gas source, control pressure at 0.4-0.5MPa, gas flow is 450-500 ml / min, and the liquid environment is 10 ° C;

[0066] Cleaning steps:

[0067] (1) Pure water spraying and backwashing of the contaminated film, the reversible contamination of the film surface is removed, and the flushing time is 15 min;

[0068] (2) Firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com