Machining process of self-tightening gasket and self-tightening nut

A processing technology, self-tightening nut technology, applied in the field of manufacturing, to achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

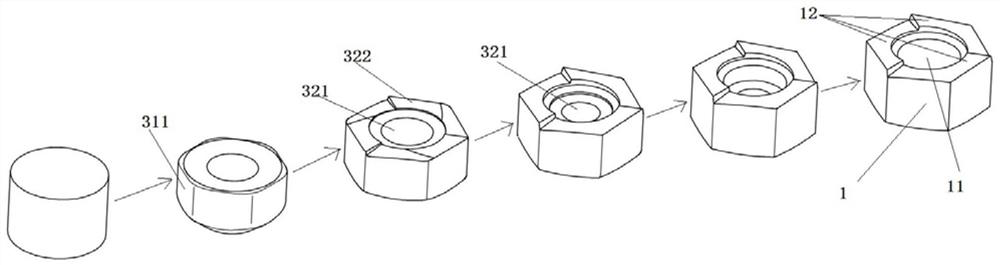

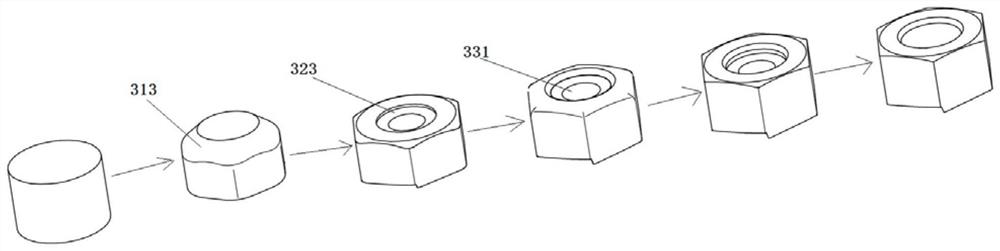

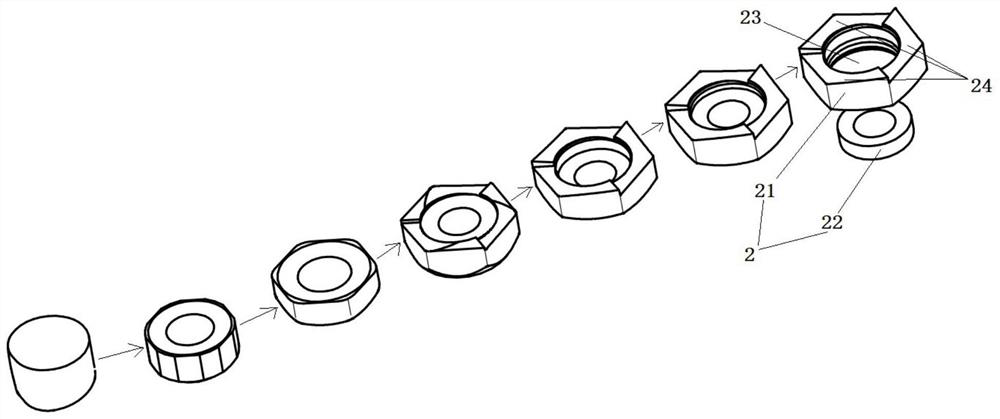

[0067] As shown in the figure, a production process of a self-tightening nut and a self-tightening washer specifically includes the following steps:

[0068] 2.1) Material forming steps: select high-temperature resistant alloy steel, and control the carbon and carbide content in it, control the carbon quality at 0.3% to 0.5%, and add a small amount of chromium, molybdenum, vanadium, nickel, manganese, silicon, and add A small amount of molybdenum or tungsten forms a new heat-resistant alloy material; the new heat-resistant alloy material forms a self-tightening nut or a self-tightening washer after cold heading. The metals chromium, molybdenum, vanadium, nickel, manganese, and silicon are added, and a small amount of molybdenum or tungsten is added, and the total amount of added metals is controlled within 1% of the overall mass. Generally, the elements to be added can be added at a mass ratio of 1:1, that is, 1g of chromium, molybdenum, vanadium, nickel, manganese, and silico...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com