Preparation method of efficient Bi2MoO6 coated BiVO4 heterojunction photoelectrode system

A heterojunction and photoelectrode technology, applied in the field of photocatalysis, can solve the problems of unremarkable photoelectrochemical performance, less research, and slow transfer of photogenerated electrons, and achieve good photoelectrochemical water splitting performance, accelerated migration, and small work efficiency. The effect of the function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

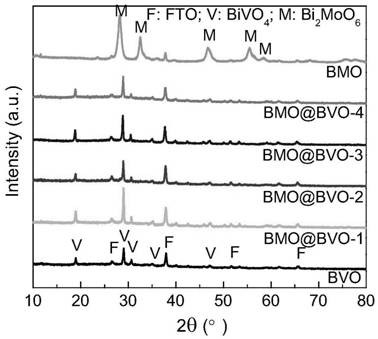

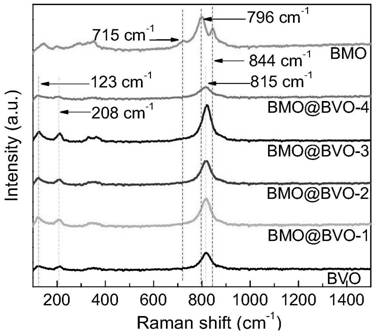

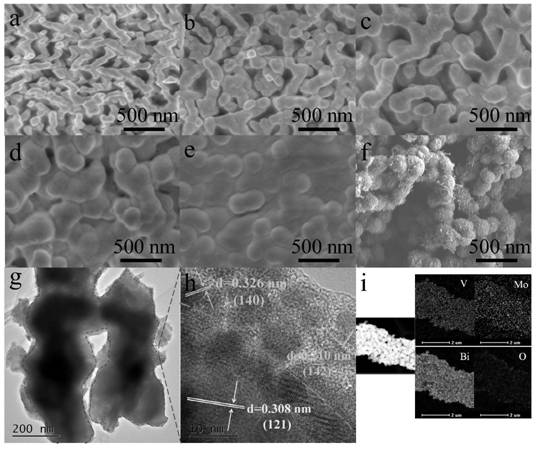

[0041] Efficient Bi 2 MoO 6 Coated BiVO 4 The preparation method of the heterojunction photoelectrode system, the concentration of the precursor is 1mM, and the specific steps include the following:

[0042] (1) Preparation of BiVO 4 Base: 1*5cm 2 FTO conductive glass as BiVO 4 growth substrate. Place FTO in a mixed solution of ethanol, acetone and water with a volume ratio of 1:1:1 and ultrasonically clean it for 15 minutes, then ultrasonically clean it in deionized water for 15 minutes, and dry it to obtain a clean FTO substrate. The FTO substrate is immersed in the deposition solution of BiOI, and the deposition conditions are: three-electrode system (FTO 1*5cm 2 as the working electrode, Ag / AgCl as the reference electrode, and Pt as the counter electrode), deposited at a constant potential of -0.1V for 300s, and obtained a BiOI film on the surface of the FTO substrate; then, take 0.6mL of 0.02M vanadium acetylacetonate by spot coating Coated on the surface of BiOI f...

Embodiment 2

[0046] Efficient Bi 2 MoO 6 Coated BiVO 4 The preparation method of the heterojunction photoelectrode system, the concentration of the precursor is 2mM.

[0047] The specific steps include the following:

[0048] (1) Preparation of BiVO 4 Base: 1*5cm 2 FTO conductive glass as BiVO 4 growth substrate. Place FTO in a mixed solution of ethanol, acetone and water with a volume ratio of 1:1:1 and ultrasonically clean it for 15 minutes, then ultrasonically clean it in deionized water for 15 minutes, and dry it to obtain a clean FTO substrate. The FTO substrate is immersed in the deposition solution of BiOI, and the deposition conditions are: three-electrode system (FTO 1*5cm 2 as the working electrode, Ag / AgCl as the reference electrode, and Pt as the counter electrode), deposited at a constant potential of -0.1V for 300s, and obtained a BiOI film on the surface of the FTO substrate, and then took 0.6mL of 0.02M vanadium acetylacetonate by spot coating Coated on the surface ...

Embodiment 3

[0051] Efficient Bi 2 MoO 6 Coated BiVO 4 The preparation method of the heterojunction photoelectrode system, the concentration of the precursor is 2mM.

[0052] The specific steps include the following:

[0053] (1) Preparation of BiVO 4 Base: 1*5cm 2 FTO conductive glass as BiVO 4 growth substrate. Place FTO in a mixed solution of ethanol, acetone and water with a volume ratio of 1:1:1 and ultrasonically clean it for 15 minutes, then ultrasonically clean it in deionized water for 15 minutes, and dry it to obtain a clean FTO substrate. The FTO substrate is immersed in the deposition solution of BiOI, and the deposition conditions are: three-electrode system (FTO 1*5cm 2 as the working electrode, Ag / AgCl as the reference electrode, and Pt as the counter electrode), deposited at a constant potential of -0.1V for 300s, and obtained a BiOI film on the surface of the FTO substrate, and then took 0.6mL of 0.02M vanadium acetylacetonate by spot coating Coated on the surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com