Tin doped ferric oxide mesocrystal nano particles and preparation method and application method thereof

A technology of iron oxide nano and iron oxide media, which is applied in chemical instruments and methods, catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, etc. It can solve the problem of iron oxide mesocrystalline nanostructure, which is rarely reported. problems, to achieve good photoelectrochemical water splitting performance, easy batch processing, and high commercial application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

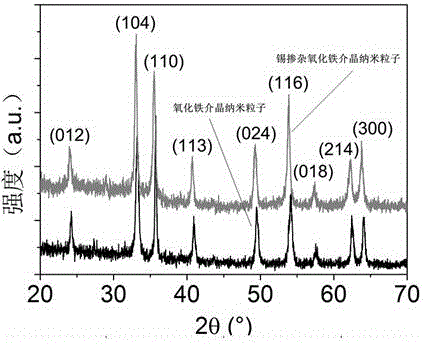

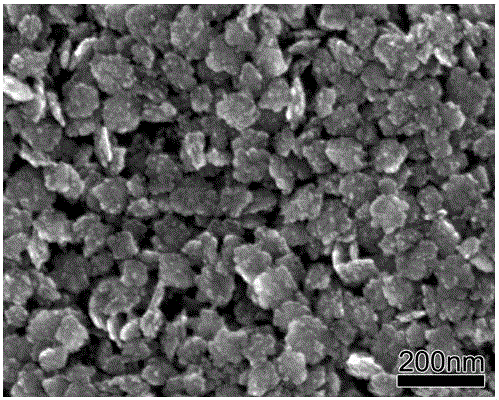

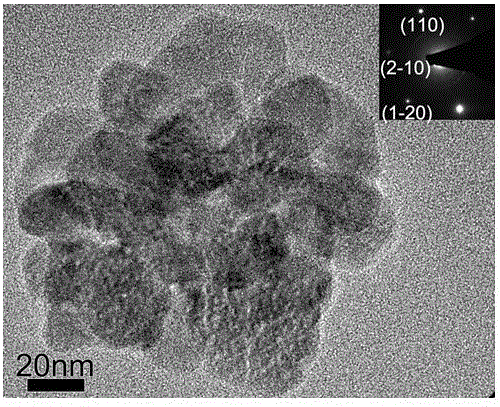

[0031] The tin-doped iron oxide mesocrystalline nanoparticles are formed by doping tin elements in iron oxide mesocrystalline nanoparticles composed of 2nm~6nm iron oxide nanoparticle crystal orientation accumulation, with a size of 40nm-220nm and a specific surface area of 36.2 m 2 / g, wherein, the molar amount of doped tin element is 0.01%~15% of the molar amount of iron element, and the doped tin element is continuously adjustable within this ratio.

[0032] The preparation method of the tin-doped iron oxide mesocrystalline nanoparticles comprises the following steps:

[0033] (1) Synthesize the iron oxide mesocrystalline nanoparticles first: dissolve iron acetylacetonate in ethanol, and ultrasonically dissolve it completely to obtain a 50mM solution, take 35mL of this solution and add it to a 50mL polytetrafluoroethylene liner, and then Add 200 microliters of deionized water, mix well, put it into a hydrothermal kettle, and react at 150°C for 24 hours; then wash the abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com