Infrared imaging electric power facility fault detector and detection method thereof

A technology for power facilities and infrared imaging, applied in radiation pyrometry, instruments, measuring devices, etc., can solve the problems of circuit breakage, simple structure, heat generation, etc., and achieve the effect of small size and easy movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

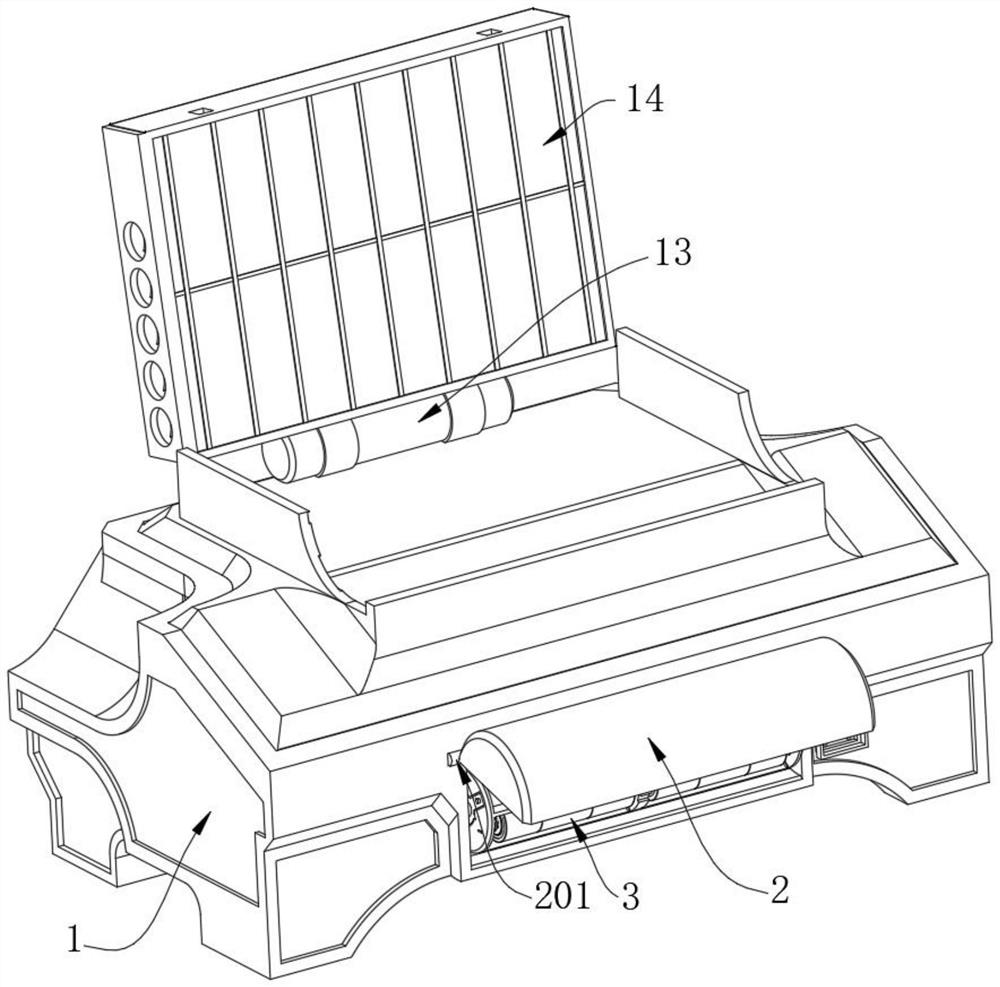

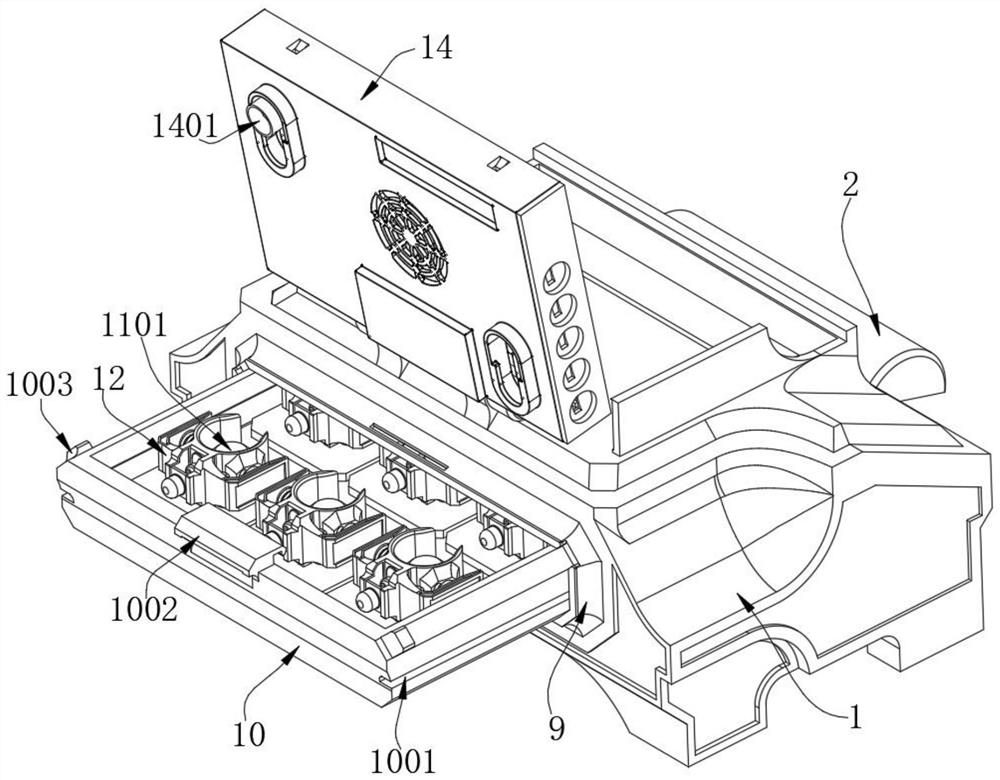

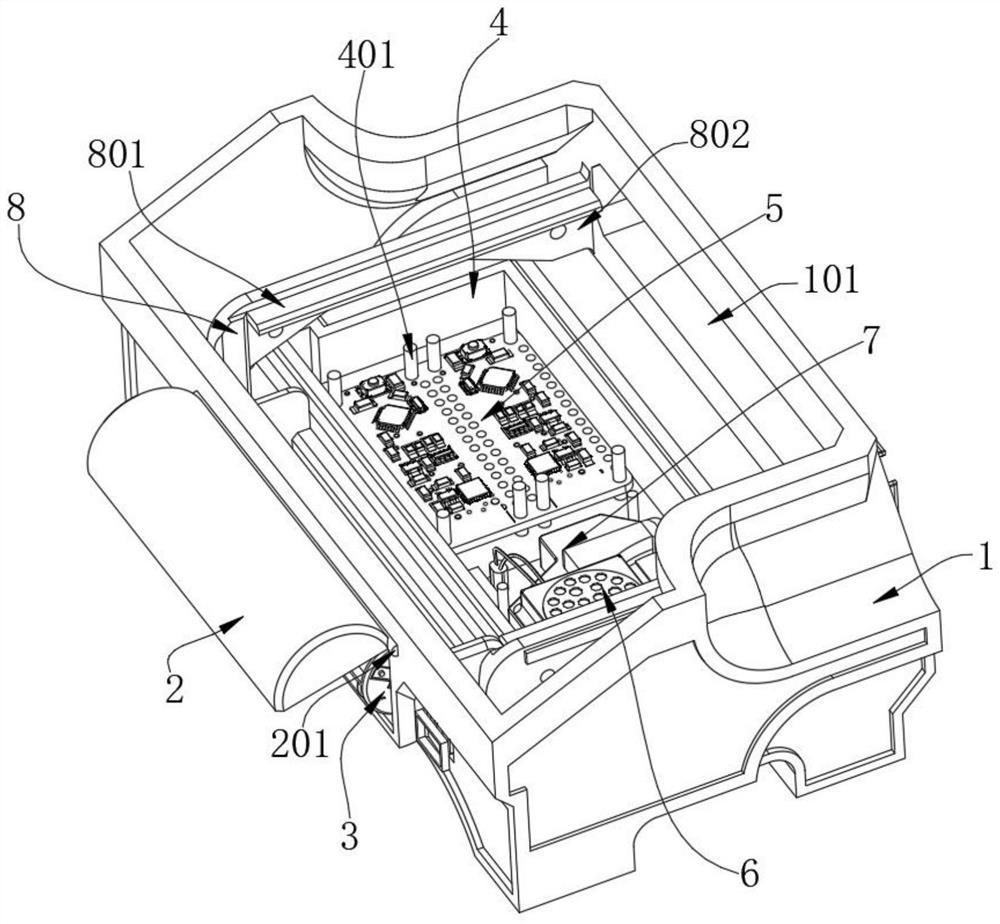

[0032] see Figure 1-9 , the present invention provides a technical solution: an infrared imaging power facility fault detector, comprising an outer shell 1 and a detection shell 12, the upper surface of the outer shell 1 is hinged with a connecting shaft 13, and the outer surface of the connecting shaft 13 is fixedly connected with The electronic display screen 14, the front surface of the electronic display screen 14 is fixedly connected with an infrared camera 1401, the front surface of the outer casing 1 is provided with a through groove 101, the rear surface of the outer casing 1 is hinged with a pin shaft 201, and the inner side wall of the outer casing 1 is fixed The first storage battery 3 is connected, the middle part of the inner wall of the outer casing 1 is integrally formed with a fixing groove 4, the inner wall of the fixing groove 4 is fixedly connected with a PCB board 5, and the inner wall of the fixing groove 4 is fixedly connected with a signal transceiver 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com