A test system for liquid phase concentration in spray section

A testing system and cross-section technology, applied in measurement devices, scattering characteristics measurement, instruments, etc., can solve the problems of inability to accurately quantitatively characterize liquid phase concentration, transient spatiotemporal concentration distribution of difficult porous sprays, etc., and achieve fast time response and reduce requirements. , control the precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

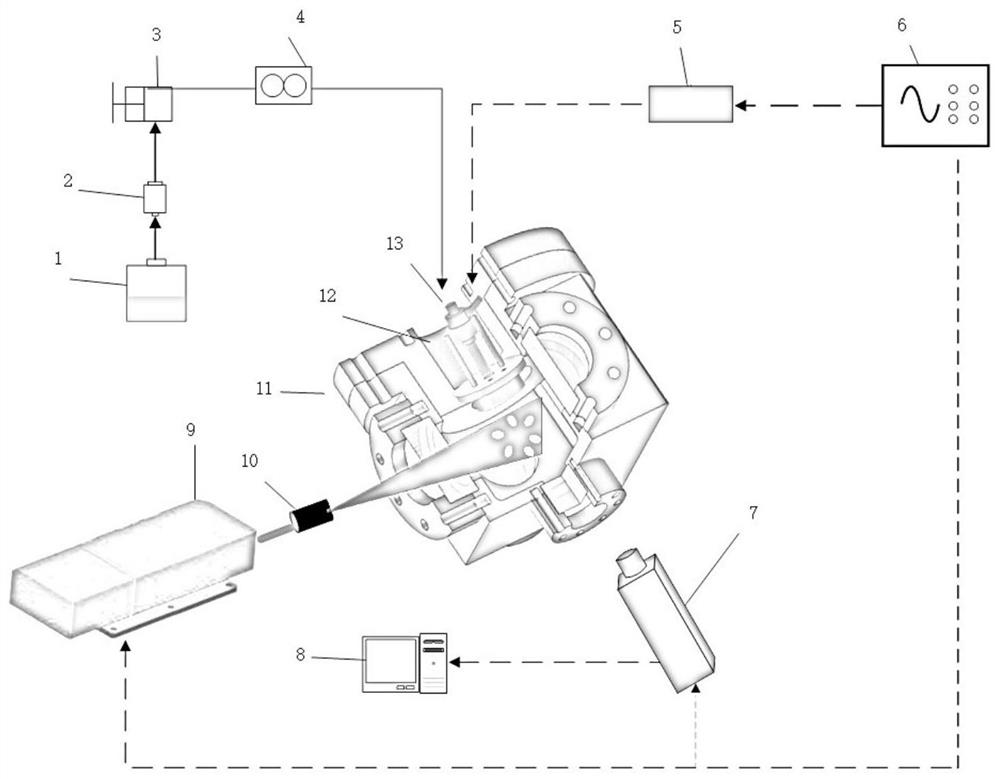

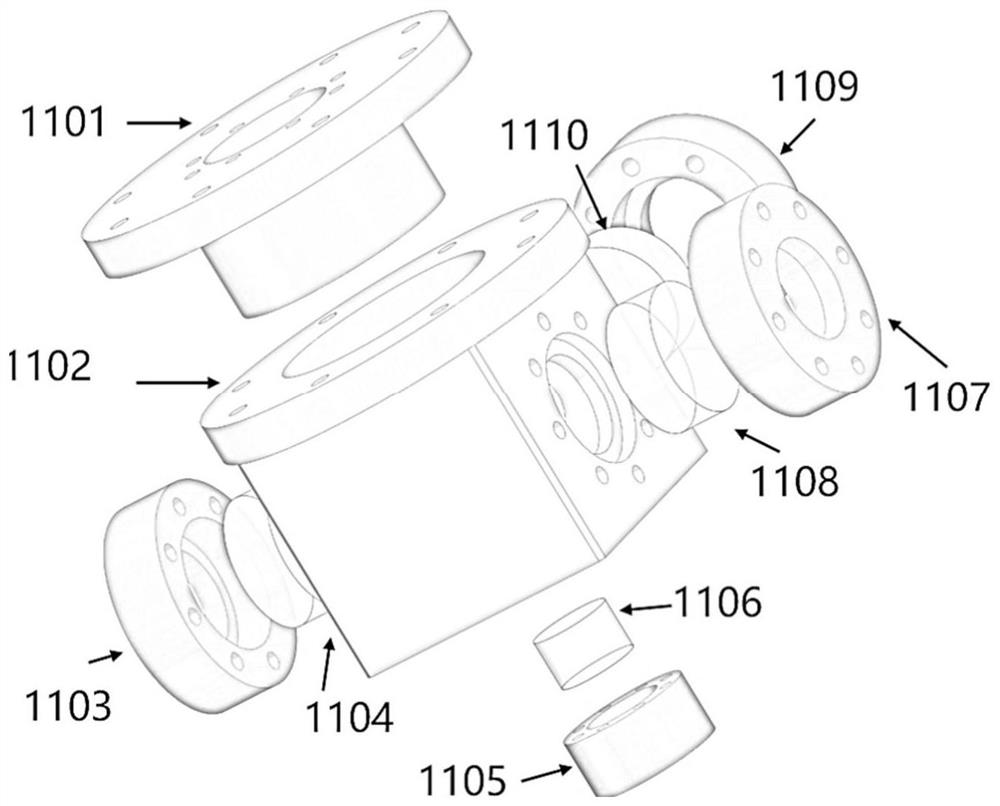

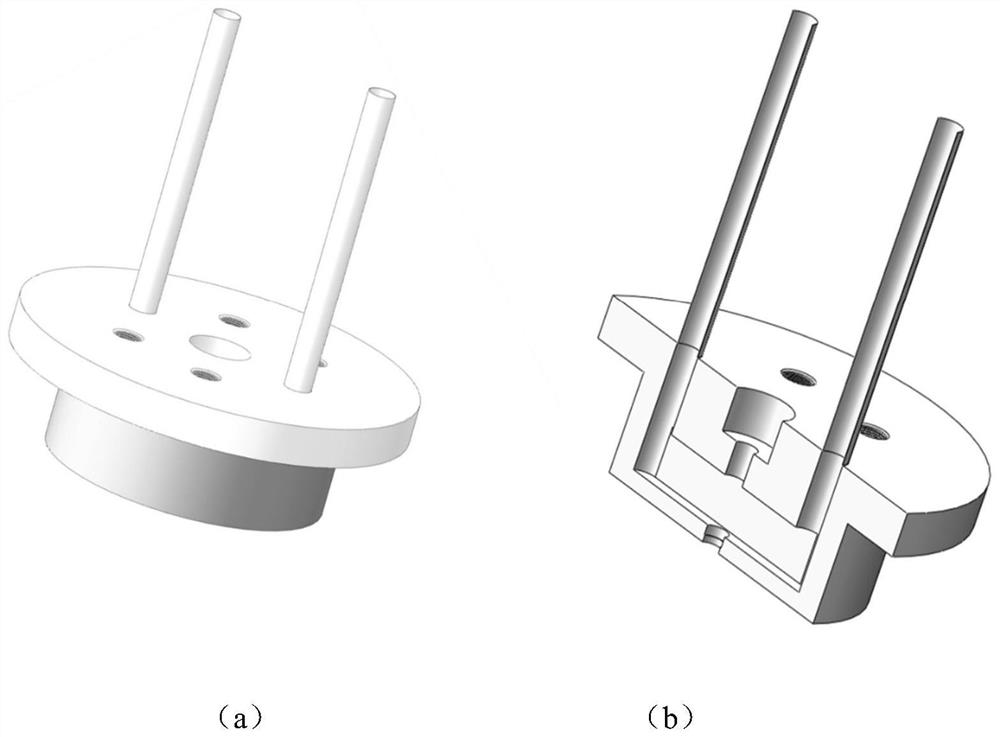

[0031] Such as figure 1 As shown, the present invention provides a test system for spray cross-section liquid phase concentration, including a fuel tank 1, a filter 2, an electric fuel pump 3, a mass flow meter 4, a fuel injector driver 5, and a signal delay trigger 6, CCD camera 7, image acquisition post-processing host computer 8, Nd:YAG laser 9, sheet light shaper 10, constant volume cavity 11, temperature control adapter 12, fuel injector 13. According to specific functions, it can be divided into: fuel supply module, signal trigger control module, temperature and pressure boundary condition setting module, optical path organization and layout module, and image signal acquisition and post-processing module.

[0032] For the fuel supply module, the fuel to be tested is stored in the fuel tank 1. The closed fuel tank design allows the test of fuel with a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com