Multilayer circuit board, board body and processing method of board body

A technology of multi-layer circuit board and processing method, which is applied in multi-layer circuit manufacturing, processing of insulating substrate/layer, printed circuit, etc., can solve the problems affecting the flatness of circuit board, cumbersome production process, and long process flow, etc. Achieve the effect of improving conductivity and stability, simplifying production procedures, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

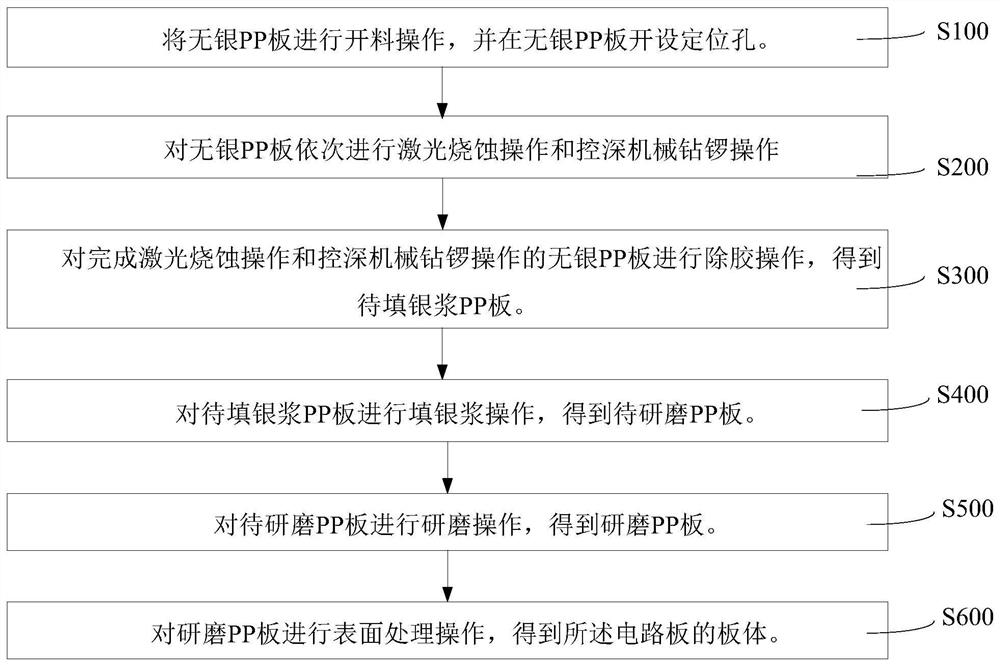

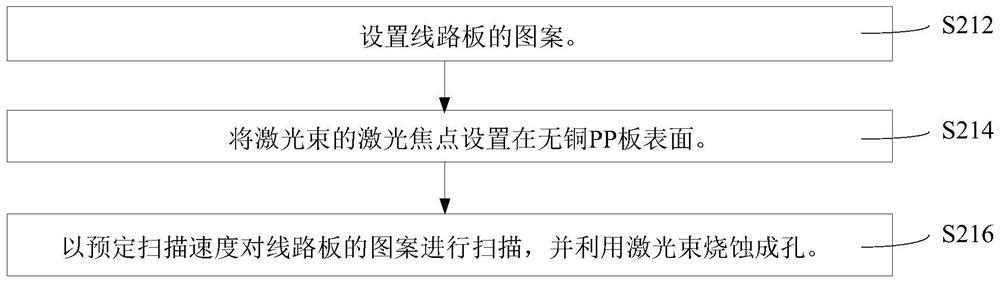

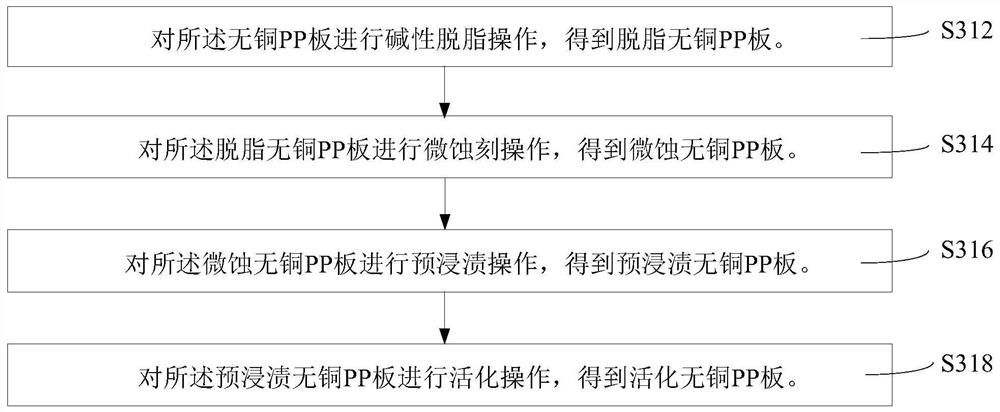

Embodiment 1

[0107]Select a silver-free PP board with high flatness for the cutting operation, and open two first positioning holes and two second positioning holes on the diagonal positions of the silver-free PP board, each first positioning hole is connected with a The central axis line of the second positioning hole is parallel to the longest side of the silver-free PP board, the distance between the first positioning hole and the longest side of the silver-free PP board is 4.9mm, and the distance between the second positioning hole and the longest side of the silver-free PP board The distance is 4.9mm, and the diameter of the positioning holes is 2mm. After determining the positioning hole, set the pattern of the circuit board on the marking software operation interface to determine the path of laser ablation, and set the laser focus of the laser beam emitted by the laser on the surface of the silver-free PP board to focus the laser energy on one point , where the output power of the l...

Embodiment 2

[0109] Select a silver-free PP board with high flatness for the cutting operation, and open two first positioning holes and two second positioning holes on the diagonal positions of the silver-free PP board, each first positioning hole is connected with a The central axis line of the second positioning hole is parallel to the longest side of the silver-free PP board, the distance between the first positioning hole and the longest side of the silver-free PP board is 5.0mm, and the distance between the second positioning hole and the longest side of the silver-free PP board The distance is 5.0mm, and the diameter of the positioning holes is 2.5mm. After determining the positioning hole, set the pattern of the circuit board on the marking software operation interface to determine the path of laser ablation, and set the laser focus of the laser beam emitted by the laser on the surface of the silver-free PP board to focus the laser energy on one point , where the output power of th...

Embodiment 3

[0111] Select a silver-free PP board with high flatness for the cutting operation, and open two first positioning holes and two second positioning holes on the diagonal positions of the silver-free PP board, each first positioning hole is connected with a The central axis line of the second positioning hole is parallel to the longest side of the silver-free PP board, the distance between the first positioning hole and the longest side of the silver-free PP board is 5.1mm, and the distance between the second positioning hole and the longest side of the silver-free PP board The distance is 5.1mm, and the diameter of the positioning holes is 3mm. After determining the positioning hole, set the pattern of the circuit board on the marking software operation interface to determine the path of laser ablation, and set the laser focus of the laser beam emitted by the laser on the surface of the silver-free PP board to focus the laser energy on one point , where the output power of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com