Composition capable of reducing content of free radicals in cigarette smoke and preparation method of composition

A technology of cigarette smoke and composition, which is applied in the preparation of tobacco, tobacco, food science, etc., can solve problems that have not been reported, and achieve the effect of cheap price, easy availability, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] In the preparation method provided by the present invention, the contact between the solid acid and the Maillard reaction intermediate can be carried out in any way, for example, they can be mixed in solid phase, liquid phase or a combination thereof. In a preferred embodiment of the present invention, the contacting can be carried out by grinding and mixing the solid acid and the solid Maillard reaction intermediate; and / or can be carried out by immersing the solid acid in the solution of the Maillard reaction intermediate.

[0033] When the contacting is carried out by grinding and mixing the solid acid and the solid Maillard reaction intermediate as described above, the mixing ratio of the solid acid and the solid Maillard reaction intermediate can be 1:5-1:1000 ( weight ratio). When the contacting is carried out by immersing the solid acid in the Maillard reaction intermediate solution as described above, the Maillard reaction intermediate solution may have a concen...

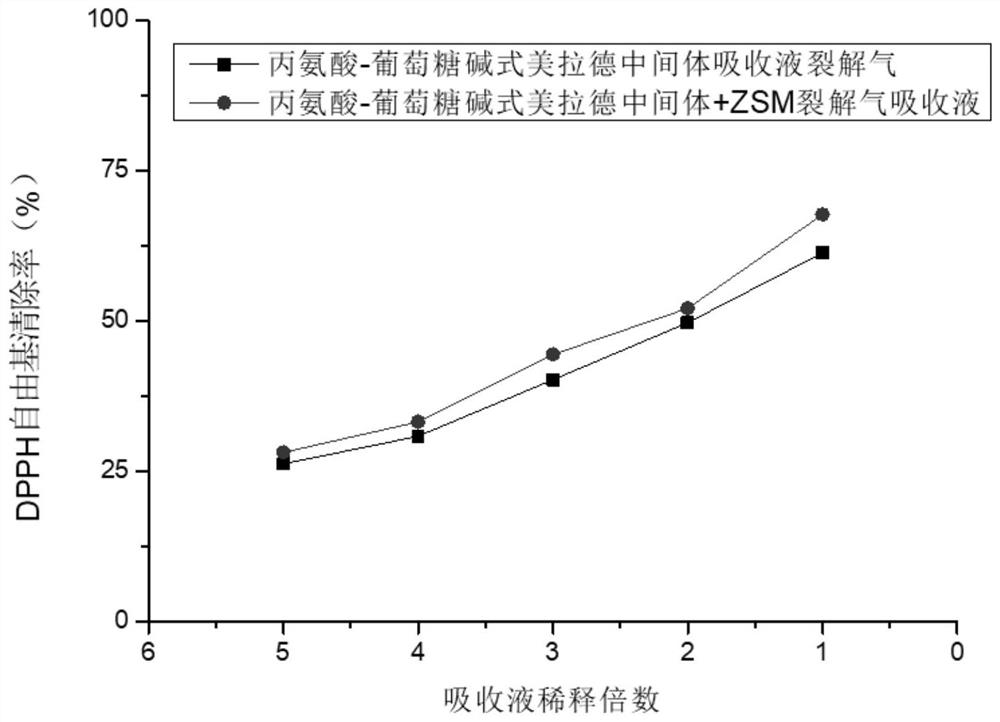

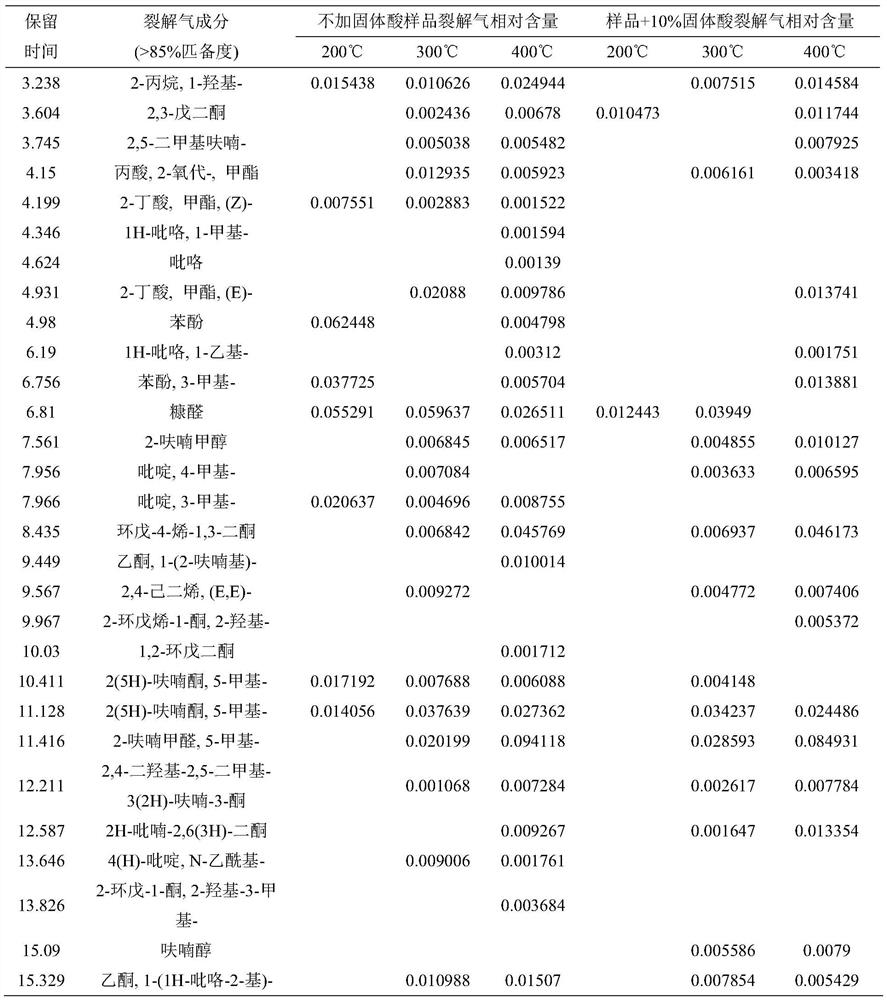

Embodiment 1

[0043] Synthesis of acidic Farmelard reaction intermediates: a certain amount of glucose and alanine (1:1 molar ratio), catalyzed by malonate at 5% (ratio to the total weight of L-alanine and glucose) Under the action, react at 65° C. for 8 hours in four times the amount (ratio to the total weight of L-alanine and glucose) of methanol. After the reaction is complete, add sodium hydroxide to neutralize it, and obtain the Maillard reaction intermediate with a membrane molecular weight cut-off of 500-5000 through membrane separator dialysis to obtain the Maillard reaction intermediate, and then freeze-dry to remove the solvent Or moisture, thus obtaining a solid Maillard intermediate.

[0044] Add the solid acid of 10% (weight ratio) in the Maillard reaction intermediate that makes above (the chemical composition of the solid acid used in the embodiment is expressed as: aNa 2 O:bAl 2 o 3 : cSiO 2 , where a<0.1%, b / c=1 / 25), and mix well.

[0045] The pyrolysis experiments wer...

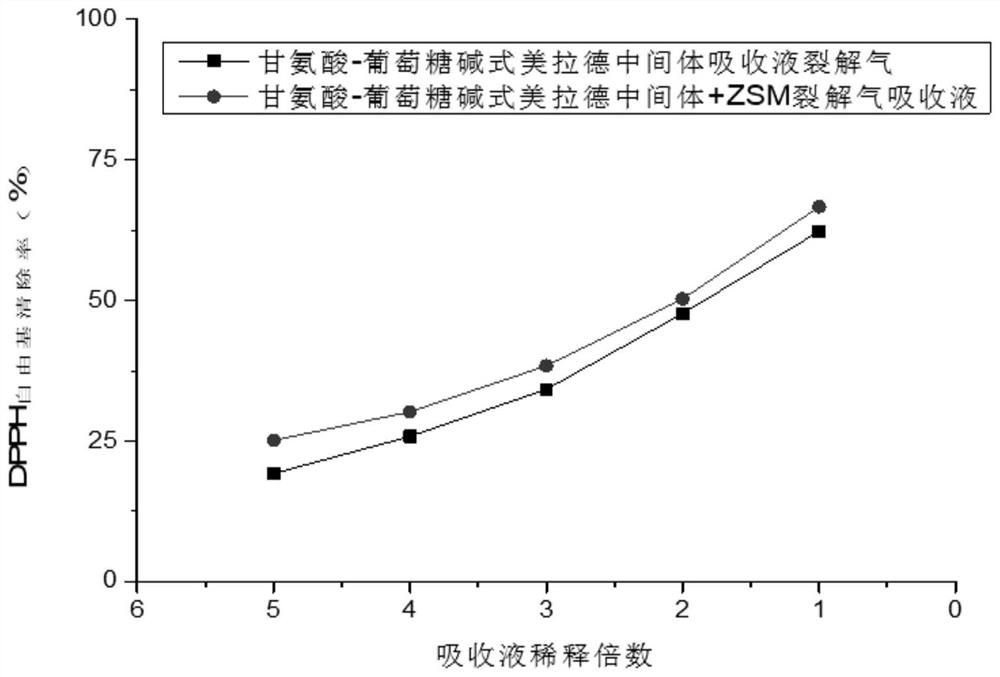

Embodiment 2

[0057] Synthesis of basic Farmelard intermediate: L-glycine and glucose are mixed in a molar ratio of 1:1, add 4 times the amount (ratio with the total weight of L-glycine and glucose) of ethylene glycol solvent, and add 10% (ratio to the total weight of L-glycine and glucose) NaOH catalyst, reacted at 130° C. for 6 hours. Then add 2.5 times the amount (with the ratio of the total weight of L-glycine and glucose) to dissolve in deionized water, then adjust the pH to neutral with 1.0mol / L HCl solution, and the obtained Maillard crude product passes through the membrane separator A Maillard reaction intermediate with a membrane molecular weight cut-off of 500-5000 is obtained by dialysis, and then freeze-dried to remove solvent or water therein, thereby obtaining a solid Maillard intermediate.

[0058]Add 10% (weight ratio) of solid acid (same as Example 1) to the Maillard reaction intermediate prepared as above, and mix well. The cracking experiments at 350°C and 600°C were ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com