Preparation method of polyanhydride modified controllable biodegradable calcium phosphate bone cement as well as product and application thereof

A calcium phosphate bone cement, biodegradable technology, applied in tissue regeneration, medical science, prosthesis, etc., can solve the problems of slow degradation rate, prolonging the self-healing time of repaired parts, mismatching of material degradation rate and new bone growth rate, etc. Achieve the effects of promoting degradation, facilitating production expansion, and controlling the rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

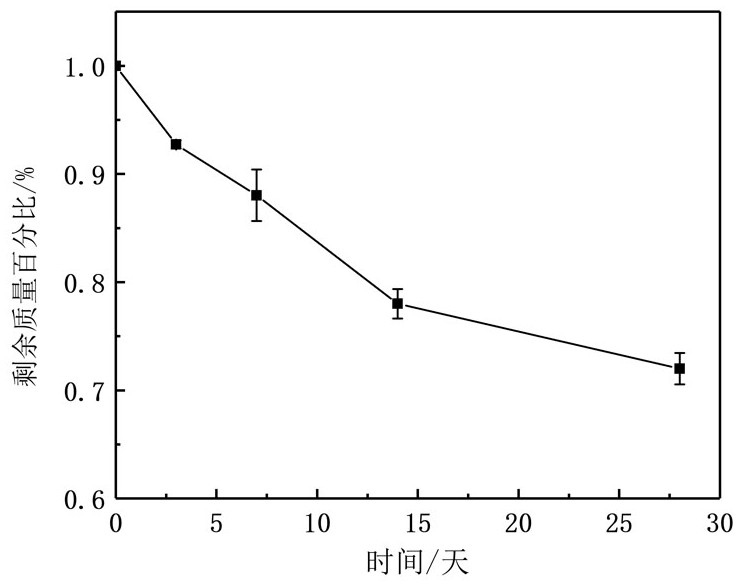

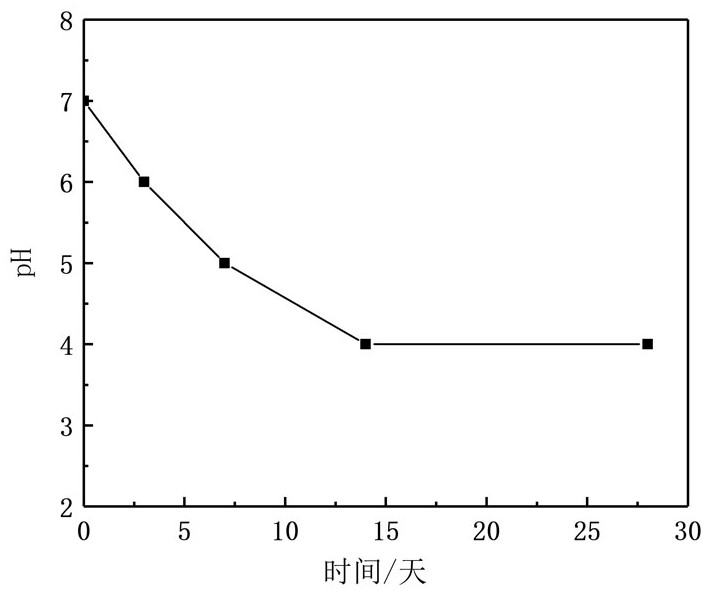

[0024] A controllable biodegradable calcium phosphate bone cement modified by polyanhydride. Alpha-tricalcium phosphate (α-TCP) is prepared by solid-state reaction method as the main component of calcium phosphate bone cement powder; a certain proportion of The polyanhydride powder is fully mixed and prepared to obtain bone cement powder; the bone cement powder is mixed with the solidification solution containing disodium hydrogen phosphate according to a certain solid-liquid ratio, and solidified to obtain calcium phosphate bone cement. By controlling the chemical composition and ratio of polyanhydride , to realize the control of the biodegradation rate of bone cement, prepared according to the following steps:

[0025] (1) Preparation of α-TCP: Mix calcium hydrogen phosphate and calcium carbonate at a molar ratio of 2:1, use pure water as the medium for wet ball milling, rotate at 400 rpm, mill for 4 hours, and the mass ratio of milling beads to powder is 2:1 1. After drying...

Embodiment 2

[0031] A polyanhydride-modified controllable biodegradable calcium phosphate bone cement, which is the same as step (1) in the embodiment, prepared according to the following steps:

[0032] The α-TCP prepared in Example 1 (1) was mixed with polysebacic anhydride at a mass ratio of 9:1, and the mixing method was dry ball milling at 150 rpm in an agate ball mill jar to obtain bone cement powder;

[0033] The bone cement powder was mixed with 2.5% disodium hydrogen phosphate solution at 2 g / mL, and the initial setting time was determined to be 11 min with reference to the standard ASTM C191.

Embodiment 3

[0035] A polyanhydride-modified controllable biodegradable calcium phosphate bone cement, which is the same as step (1) in the embodiment, prepared according to the following steps:

[0036] The α-TCP prepared in Example 1 (1) was mixed with polyanhydride p (CPP-co-SA) at a mass ratio of 95:5, and the mixing method was dry ball milling in an agate ball mill jar at 150rpm to obtain bone cement powder ;

[0037] The bone cement powder was mixed with 2.5% disodium hydrogen phosphate solution at 2 g / mL, and the initial setting time was determined to be 10 min with reference to the standard ASTM C191.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com