SCR denitration system

A denitration and pipeline technology, applied in the field of SCR denitration system, can solve the problem of inappropriate denitration treatment, and achieve the effect of promoting the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

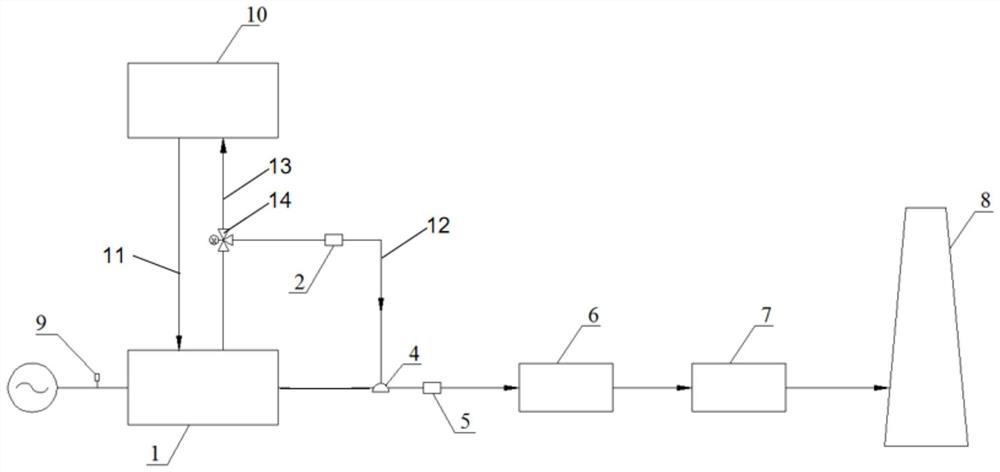

[0037] This embodiment provides an SCR denitrification system, including a cooling water tank 10, an internal combustion engine generator set 1, an SCR denitrification device 6, a spray unit 4, a flue gas hot water type lithium bromide machine 7, and a chimney 8. The internal combustion engine generator set 1 includes a smoke gas outlet, intercooled water inlet and intercooled water outlet, the SCR denitrification device 6 communicates with the flue gas outlet through a flue, the cooling water tank 10 communicates with the intercooled water inlet through a first pipeline 11, and the spray The shower unit 4 communicates with the intercooled water outlet through the second pipeline 12, the spray unit 4 is arranged in the flue, the SCR denitrification device 6, the flue gas hot water type lithium bromide machine 7 and the chimney 8 are connected in sequence , so that the flue gas after the denitrification reaction is completed enters the flue gas hot water type lithium bromide mac...

Embodiment 2

[0063] Such as figure 2 As shown, this embodiment provides an SCR denitrification system, which differs from the SCR denitrification system provided in Embodiment 1 only in that the SCR denitrification system does not include a second temperature sensor and a second control module, but includes:

[0064] Generating power testing device 8 is electrically connected with the internal combustion engine generator set 1;

[0065] The third control module (not shown in the figure), the third control module is electrically connected with the generating power testing device 8 and the communication valve 14, so as to control The opening and closing of the spray unit 4 .

[0066] Specifically, the generating power test device 8 is used to test the generating power of the internal combustion engine generator set 1, and the third control module is preset to obtain a generating power range corresponding to the temperature window of the medium-temperature SCR catalyst; When the above powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com