Preparation method and application of pH-sensitive water-absorption expansion resin

A water-absorbing swelling and sensitivity technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of plugging micro-cracks, environmental inconsistencies, etc., and achieve the goal of reducing water absorption, reducing water absorption, and strong water retention capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

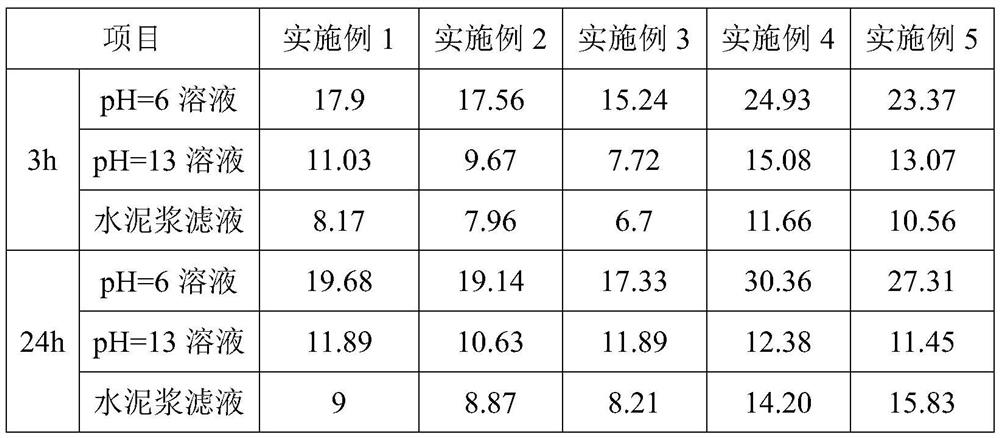

Examples

Embodiment 1

[0023] The preparation method of the pH-sensitive water-swellable resin of this embodiment comprises the following steps:

[0024] Measure 40g of deionized water into a three-necked beaker, turn on the magnetic stirrer, blow in nitrogen, and then add 8.34g of acrylamide, 1.67g of acrylic acid, 4.16g of methacryloyloxyethyltrimethylammonium chloride, 0.14g of N ,N-Methylenebisacrylamide, stir for 10min, then slowly add 1mol / L acetic acid solution for neutralization, make the whole system neutral or weakly acidic, add 0.13g of potassium persulfate, stop feeding nitrogen, and continue stirring After 20 minutes, put it into an 80°C constant temperature water bath to continue the reaction, and control the reaction time to 6 hours. The product was taken out and repeatedly soaked in pure water for 24 hours to remove impurities, and the deionized water was changed every 8 hours. Finally put it into a 99°C oven for drying and pulverization.

Embodiment 2

[0026] The preparation method of the pH-sensitive water-swellable resin of this embodiment comprises the following steps:

[0027] Measure 40g of deionized water into a three-necked beaker, turn on the magnetic stirrer, blow in nitrogen, and then add 6.25g of acrylamide, 1.25g of acrylic acid, 6.25g of methacryloyloxyethyltrimethylammonium chloride, 0.14g of N , N-methylenebisacrylamide, stirred for 10min. Then slowly add 1mol / L acetic acid solution for neutralization, so that the whole system is neutral or weakly acidic, add 0.13g of potassium persulfate, stop feeding nitrogen, continue stirring for 20min, and put it in a constant temperature water bath at 80°C to continue the reaction. The control reaction time is 6h. The product was taken out and repeatedly soaked in pure water for 24 hours to remove impurities, and the deionized water was changed every 8 hours. Finally put it into a 99°C oven for drying and pulverization.

Embodiment 3

[0029] The preparation method of the pH-sensitive water-swellable resin of this embodiment comprises the following steps:

[0030] Measure 40g of deionized water into a three-necked beaker, turn on the magnetic stirrer, blow in nitrogen, and then add 4.16g of acrylamide, 0.83g of acrylic acid, 8.34g of methacryloyloxyethyltrimethylammonium chloride, 0.13g of N , N-methylenebisacrylamide, stirred for 10min. Then slowly add 1mol / L acetic acid solution for neutralization, make the whole system neutral or weakly acidic, add 0.13g of potassium persulfate, stop feeding nitrogen, continue stirring for 20min, put it into a constant temperature water bath at 80°C for continuous reaction, and control The reaction time is 6h. The product was taken out and repeatedly soaked in pure water for 24 hours to remove impurities, and the deionized water was changed every 8 hours. Finally, put it into a 99°C oven for drying and crushing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com