Preparation method of paper-plastic composite adhesive

A paper-plastic composite and adhesive technology, applied in the direction of adhesives, adhesive types, adhesive additives, etc., can solve the problems of many pores, rough paper surface, etc., and achieve the effect of simple operation, good hygienic performance, and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

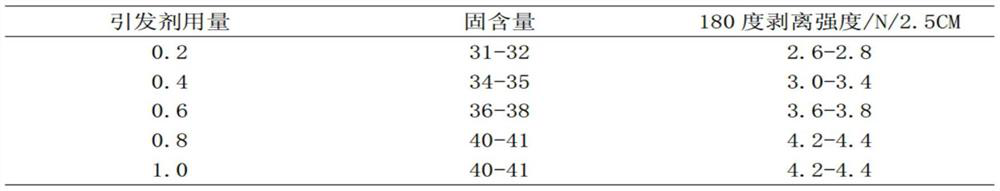

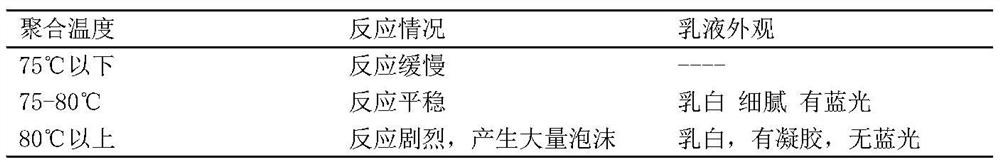

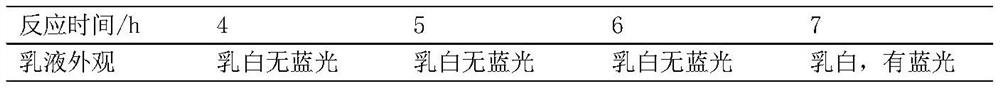

Examples

Embodiment 1

[0028] A preparation method of paper-plastic composite adhesive, comprising the following steps:

[0029] Step 1, preparation of emulsified rosin

[0030] (1) Add 120 grams of rosin to a three-necked flask, add 100 ml of alcohol, heat to 80°C until the rosin dissolves, add 6 grams of rosin emulsifier and 60 ml of 80°C hot water,

[0031] Stir vigorously for 30 minutes until milky white, and cool down to 70°C;

[0032] (2) Add 40 ml of 10wt% polyvinyl alcohol solution dropwise under strong stirring, finish dripping within 30 minutes, continue stirring for 30 minutes, cool down and discharge, the product is light yellow viscous liquid with a solid content of 42%, which is rosin viscosity-increasing emulsion ;

[0033] Step 2, emulsion synthesis and preparation of paper-plastic composite adhesive

[0034] (1) Pre-emulsification: Get 4 grams of emulsifier solution and put it into a three-necked flask, add 200 grams of mixed monomer dropwise for 1 hour under stirring, and obtain...

Embodiment 2

[0071] A preparation method of paper-plastic composite adhesive, comprising the following steps:

[0072] Step 1, preparation of emulsified rosin

[0073] (1) Add 110 grams of rosin to a three-necked flask, add 95 ml of alcohol, heat to 80°C until the rosin dissolves, add 5.5 grams of rosin emulsifier and 55 ml of 80°C hot water, stir vigorously for 30 minutes until milky white, and cool down to 70°C;

[0074] (2) Under strong stirring, add 35 milliliters of 10wt% polyvinyl alcohol solution dropwise, finish dripping within 30 minutes, continue stirring for 30 minutes, cool down and discharge, the product is a light yellow viscous liquid with a solid content of 32%, which is rosin thickening Lotion;

[0075] Step 2, emulsion synthesis and preparation of paper-plastic composite adhesive

[0076] (1) Pre-emulsification: Take 3.5 grams of emulsifier solution and put it into a three-necked flask, and drop the mixed monomer into the three-necked flask within 1 hour under stirring ...

Embodiment 3

[0083] A preparation method of paper-plastic composite adhesive, comprising the following steps:

[0084] Step 1, preparation of emulsified rosin

[0085] (1) Add 135 grams of rosin into a three-necked flask, add 105 ml of alcohol, heat to 80°C until the rosin dissolves, add 6.5 grams of rosin emulsifier and 65 ml of 80°C hot water, stir vigorously for 30 minutes until milky white, and cool down to 70°C;

[0086] (2) Under vigorous stirring, add 45 milliliters of 10wt% polyvinyl alcohol solution dropwise, finish dripping within 30 minutes, continue stirring for 30 minutes, cool down and discharge, the product is light yellow viscous liquid with a solid content of 45%, which is rosin thickening Lotion;

[0087] Step 2, emulsion synthesis and preparation of paper-plastic composite adhesive

[0088] (1) Pre-emulsification: Take 4.5 grams of emulsifier solution and put it into a three-necked flask, and drop the mixed monomer into the three-necked flask within 1 hour under stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com