A kind of two-component epoxy resin encapsulation glue and its preparation method and application

A technology of epoxy resin and encapsulating glue, which is applied in the direction of epoxy resin glue, adhesive, non-polymer adhesive additives, etc., can solve the problems of poor rheological stability, insufficient hanging glue, short pot life, etc. Achieve excellent rheological stability and viscosity stability, improve viscosity stability, rheological stability, and good rheological stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

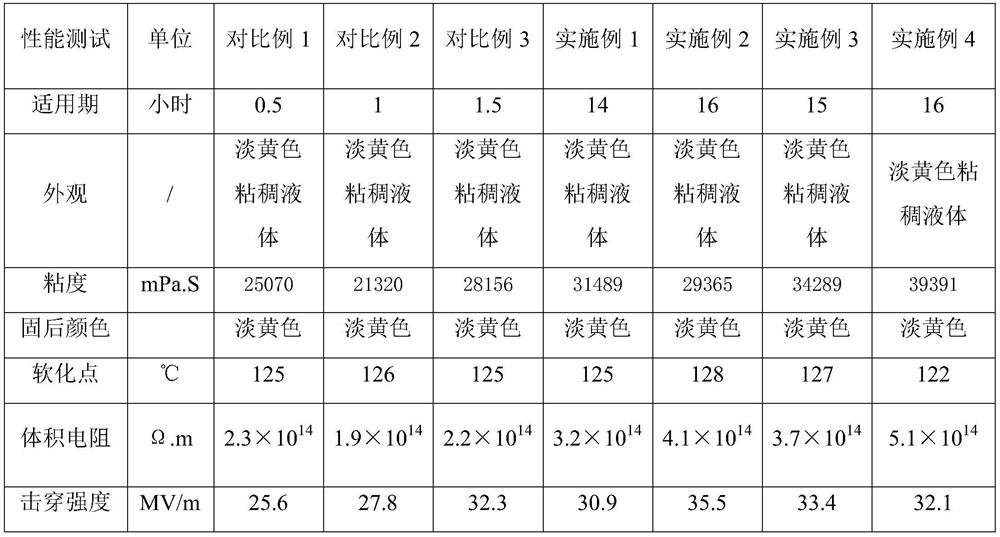

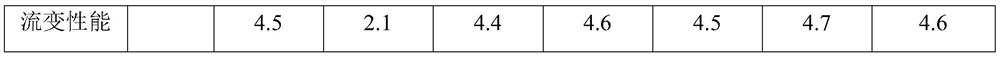

Examples

Embodiment 1

[0039] This example provides a two-component epoxy resin encapsulant, which includes component A and component B.

[0040] Among them, the raw materials of component A include 40 kg E54 bisphenol A epoxy resin, 40 kg E51 bisphenol A epoxy resin, 4 kg Span-80, 4 kg EL-10, 1 kg fumed silica, 18.5 kg Wollastonite, 0.5 kg rheology additive, 0.1 kg defoamer;

[0041] The raw materials of component B include 48 kg of methyltetrahydrophthalic anhydride, 0.2 kg of fumed silica, 0.2 kg of modified curing accelerator, 0.2 kg of rheology additive, and 25 g of defoamer.

[0042] The preparation method of described two-component epoxy resin encapsulant comprises the steps:

[0043] Preparation of A component:

[0044] Preparation of modified epoxy resin: heat 20 kg of E54 bisphenol A epoxy resin and 20 kg of E51 bisphenol A epoxy resin, and raise the temperature to 210±5°C, then add 4 kg of Span-80 and 4 kg of EL -10, and stir evenly; keep the system temperature at 210±5°C for 60 minute...

Embodiment 2

[0050] This example provides a two-component epoxy resin encapsulant, which includes component A and component B.

[0051] Among them, the raw materials of component A include 80 kg of E54 bisphenol A epoxy resin, 4 kg of EL-10, 4 kg of EL-20, 1 kg of fumed silica, 18.5 kg of wollastonite, 0.5 kg of rheological additives, 0.1 kg of defoamer;

[0052] The raw materials of component B include 48 kg of methyl hexahydrophthalic anhydride, 0.2 kg of fumed silica, 0.2 kg of modified curing accelerator, 0.2 kg of rheology additive, and 25 g of defoamer.

[0053] The preparation method of described two-component epoxy resin encapsulant comprises the steps:

[0054] Preparation of A component:

[0055] Preparation of modified epoxy resin: Heat 40 kg of E54 bisphenol A epoxy resin to 210±5°C, then add 4 kg of EL-10 and 4 kg of EL-20, and stir evenly; keep the system temperature at React at 210±5°C for 60 minutes, then add the remaining epoxy resin; keep the system temperature at 210±...

Embodiment 3

[0061] This example provides a two-component epoxy resin encapsulant, which includes component A and component B.

[0062] Among them, the raw materials of component A include 80 kg of E51 bisphenol A epoxy resin, 4 kg of Span-80, 4 kg of Span-20, 1 kg of fumed silica, 18.5 kg of wollastonite, and 0.5 kg of rheological aids. agent, 0.1 kg of defoamer;

[0063] The raw materials of component B include 24 kg of methyl tetrahydrophthalic anhydride, 24 kg of tung oil anhydride, 0.2 kg of fumed silica, 0.2 kg of modified curing accelerator, 0.2 kg of rheology additive, and 25 g of defoamer.

[0064] The preparation method of described two-component epoxy resin encapsulant comprises the steps:

[0065] Preparation of A component:

[0066] Preparation of modified epoxy resin: Heat 40 kg of E51 bisphenol A epoxy resin to 210±5°C, then add 4 kg of Span-80 and 4 kg of Span-20, and stir evenly; keep the system React at 210±5°C for 60 minutes, then add the remaining epoxy resin; keep t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com