A kind of asphalt-based joint filling glue and preparation method thereof

A joint-filling glue and asphalt-based technology, applied in the field of joint-filling glue, can solve the problems of poor low-temperature performance of asphalt joint-filling glue, and achieve the effects of strong elasticity, improved low-temperature resistance, and difficulty in absorbing water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

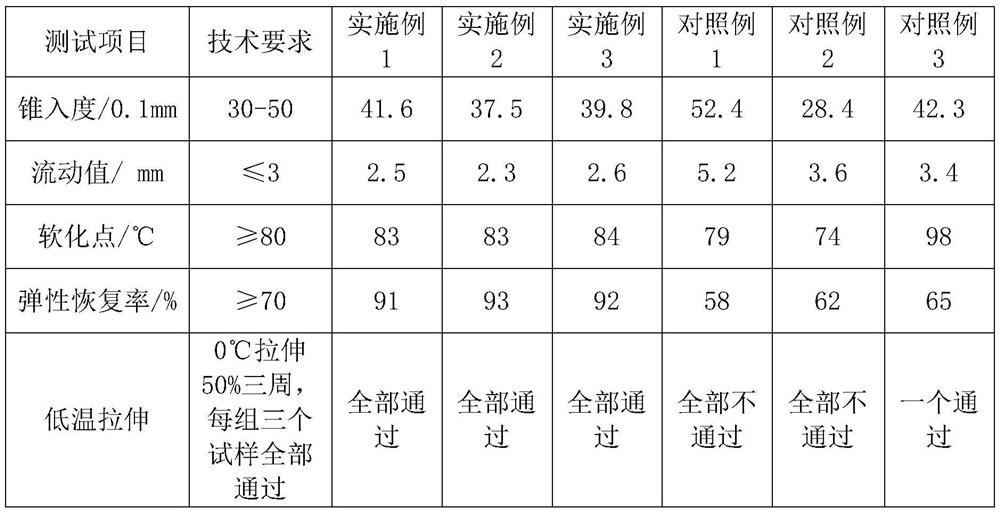

Examples

Embodiment 1

[0018] 20 kg of gelatin was dissolved in 30 kg of an aqueous solution containing 30 wt % of propylene glycol, then 6 kg of alkyd resin was added and heated to 85° C., and then 0.7 kg of catalyst dibutyltin dilaurate was added, reacted for 3 hours, filtered and dried to obtain modified gelatin.

[0019] Then, 80kg of No. 70 petroleum asphalt was heated to 180°C in a high-speed shearing machine, then 4kg of modified gelatin and 8kg of rubber powder were added for shearing for 35min, and then 1kg of 1,2,3,4-butanetetraol and 2kg of terephthalene were added. The mixture of bishydroxyethyl formate is continuously sheared for 10 minutes, cooled, lowered to room temperature, sealed and stored to obtain an asphalt-based joint glue.

Embodiment 2

[0021] 24 kg of gelatin was dissolved in 30 kg of an aqueous solution containing 32 wt % of propylene glycol, then 5 kg of alkyd resin was added and heated to 90° C., then 0.5 kg of catalyst dibutyltin dilaurate was added, reacted for 2.5 hours, filtered and dried to obtain modified gelatin.

[0022] Then, 100kg of No. 90 petroleum asphalt was heated to 190°C in a high-speed shearing machine, then 5kg of modified gelatin and 10kg of rubber powder were added for shearing for 30min, and then 1kg of 1,2,3,4-butanetetraol and 1.8kg of The mixture of bis-hydroxyethyl phthalate is continuously sheared for 10 minutes, cooled, lowered to room temperature, sealed and stored to obtain an asphalt-based joint glue.

Embodiment 3

[0024] 26 kg of gelatin was dissolved in 30 kg of an aqueous solution containing 35 wt % of propylene glycol, then 5 kg of alkyd resin was added and heated to 80° C., and then 0.6 kg of catalyst dibutyltin dilaurate was added, reacted for 3 hours, filtered and dried to obtain modified gelatin.

[0025] Then, 90kg of No. 80 petroleum asphalt was heated to 190°C in a high-speed shearing machine, then 3kg of modified gelatin and 10kg of rubber powder were added for shearing for 30min, and then 1kg of 1,2,3,4-butanetetraol and 2kg of terephthalene were added. The mixture of bishydroxyethyl formate is continuously sheared for 10 minutes, cooled, lowered to room temperature, sealed and stored to obtain an asphalt-based joint glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com