Breathing type double-layer glass curtain wall system

A technology of double-layer glass and outer glass, which is applied in the field of breathing double-layer glass curtain wall system and ventilation interlayer, which can solve the problems of energy-saving curtain wall, high power consumption of equipment, loss, etc., so as to improve energy-saving effect and reduce energy consumption , the effect of comfortable environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

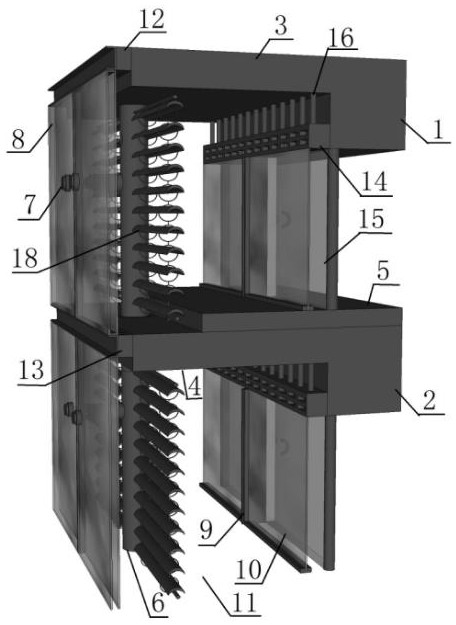

[0035] Such as figure 1 As shown, the upper structural beam 1 and the upper deck 3, the lower structural beam 2 and the lower deck 4 are poured into an integral structure, an indoor floor 5 is installed on the lower deck 4, and the outer end of the lower deck 4 exceeds the interior floor 5 by a section, and Install support bar 6 on a section beyond indoor floor 5, support bar 6 is the round steel used for point support, support bar 6 passes through upper deck 3 and lower deck 4, and perforation is when pouring upper deck 3 and lower deck 4 It has been reserved to install the first support device 7 on the support rod 6. The first support device 7 is a connecting device used for point-supporting the glass curtain wall, including a connecting piece used for fixing the outer glass curtain wall 8, such as The splicing claws made of metal alloys such as stainless steel, and the fasteners that fix the splicing pieces on the support rod 6, the outer glass curtain wall 8 is located out...

Embodiment 2

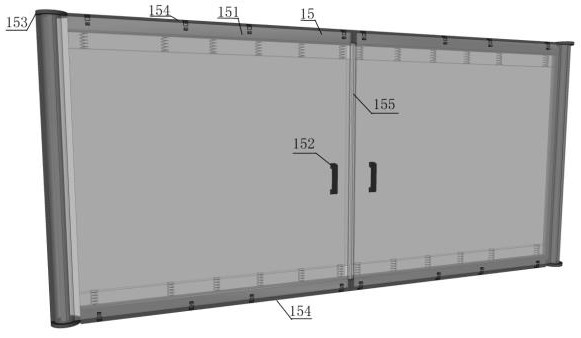

[0043] On the basis of Embodiment 1, the glass door 15 can use a sliding door and a revolving door. The sliding door can be closed and opened through the sliding door body to interrupt the air flow on both sides of the glass door 15. The revolving door can pass through the revolving door body. Realize closing and opening, so as to interrupt the air flow on both sides of the glass door 15 .

[0044] Of course, the space for the hot air flow opened by the sliding door and the revolving door is not as large as the openable space of the swing door. As an improved method of the glass door 15 in Embodiment 1, the structure of the glass door 15 can be as follows: Figure 2-6 shown.

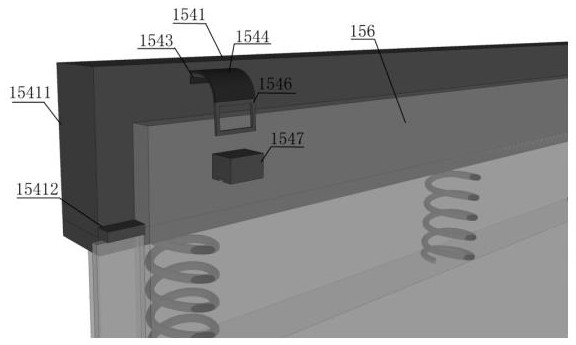

[0045] Glass door 15 comprises door body 151 and door body handle 152, and door body handle 152 can use opaque material, is conducive to user's identification, and door body handle 152 is arranged at the middle position when two fan glass doors 15 are integrally closed, is convenient to The glass door 1...

Embodiment 3

[0053] On the basis of Example 2, such as Figure 7 As shown, a sloping roof 17 can also be installed on the third ventilation device 14. The sloping roof 17 can consider the function of aesthetics. One section of the sloping roof 17 extends from the upper surface of the third ventilation device 14 to the side of the superstructure beam 1. One section is far away from the third ventilation device 14 and extends upwards to the upper deck 3. The inclined roof 17 can use a keel, and the suspenders are fixed on the upper deck 3. The inclined roof 17 guides the hot air discharged from the third ventilation device 14 to the first ventilation. The device 12 prevents hot air from gathering at the upper corner of the third ventilation device 14, which is not conducive to exhausting.

[0054] In order to cooperate with absorbing the hot air flow introduced by the inclined roof 17 below, the second ventilation device 13 is concavely installed on the outer end of the lower floor plate 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com