Continuous sucker rod operation vehicle and method

A sucker rod and working vehicle technology, which is applied to drill pipes, earth-moving drilling, drilling equipment, etc., can solve the problems of easy damage to continuous sucker rods, inconvenient transportation and scattered equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

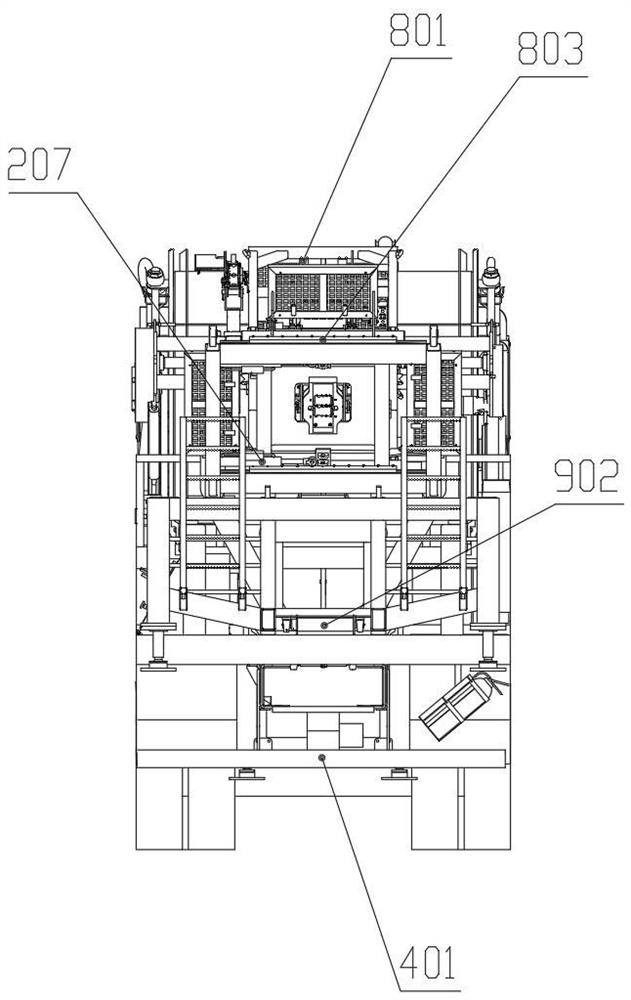

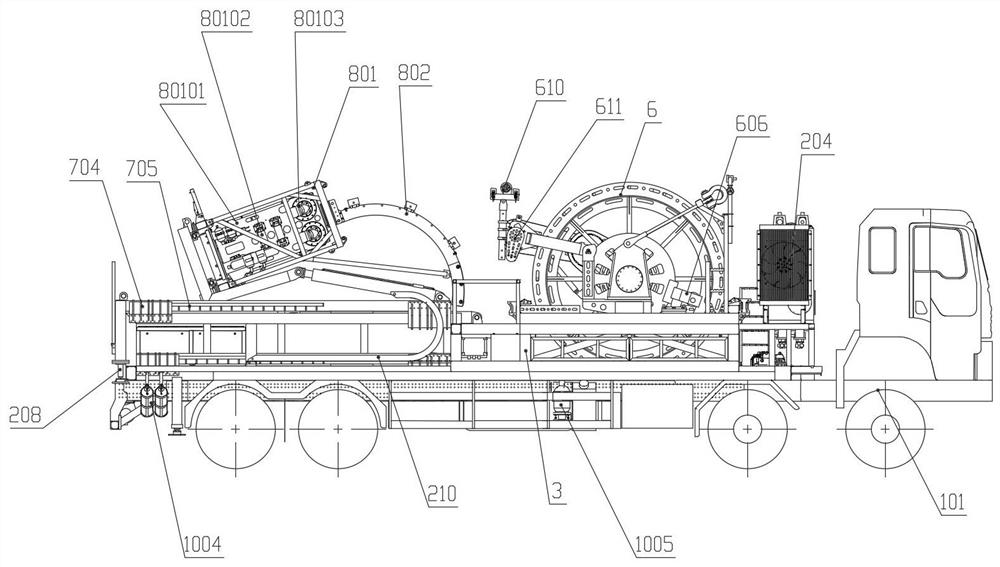

[0055] Refer to attached Figure 1~11 , a continuous sucker rod operation vehicle, including power system 1, control system 2, sub-frame beam 3, side rear protection 4, pipeline shield 5, sucker rod drum 6, sliding platform 7, continuous sucker rod injection Head assembly 8, rod traction assembly 9, supporting accessories assembly 10, continuous sucker rod 11.

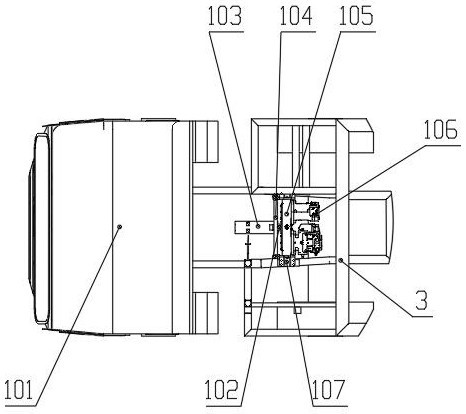

[0056] The power system 1 includes a chassis vehicle 101 as a source of transportation and power, a transmission shaft 102 connected to the power take-off of the chassis vehicle, a transmission shaft shield 103 with a C-shaped structure, a shield bracket 104 with a door-shaped cross-bar structure, Transmission case 105, the hydraulic pump 106 that converts mechanical energy into hydraulic power; Wherein the transmission shaft 102, the transfer case 105 and the hydraulic pump are connected in series, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com