Lens refractive index measuring device and measuring method thereof

A measuring device and refractive index technology, applied in the field of optical measurement, can solve problems such as complex operation, difficult detection, and high difficulty, and achieve the effect of simple operation and fast detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

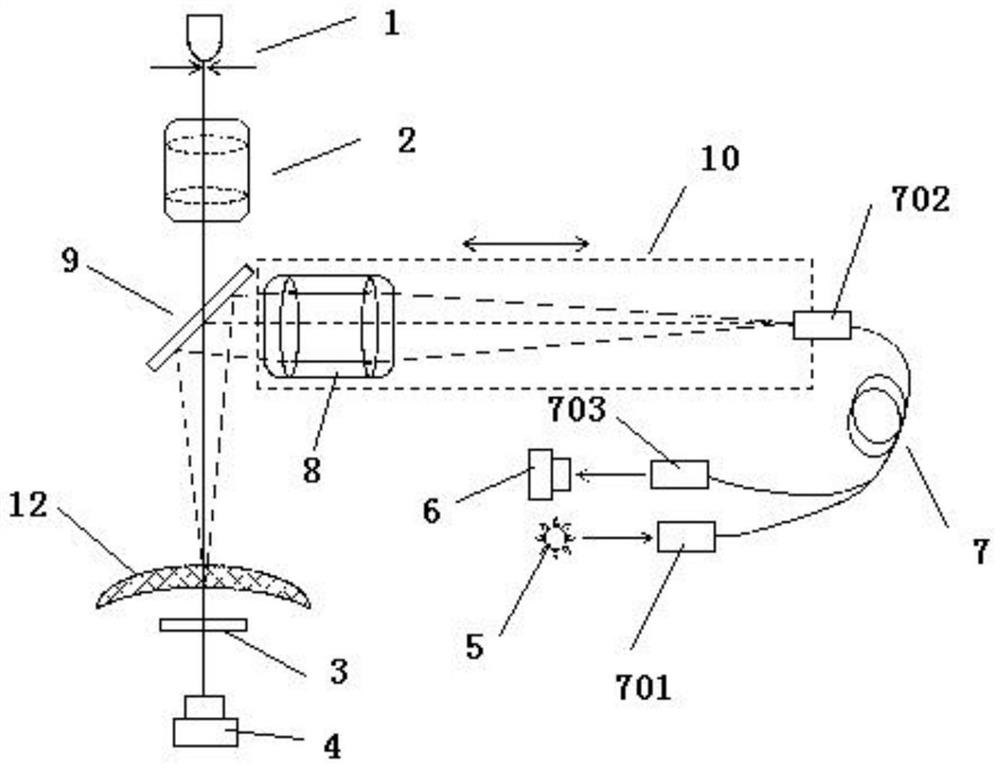

[0029] The lens refractive index measuring device of the present invention includes a diopter measurement module, a confocal reflection measurement module and a measured lens.

[0030] The diopter measurement module includes a first light source module 1 , a first collimator lens 2 , a Hartmann diaphragm 3 and a first photodetector 4 . The first light source module 1 includes a first light source and a first hole, and a light-transmitting hole is provided on the side of the first hole near the light-emitting surface of the first light source; The light emitted by the light source is emitted after passing through the light transmission hole. The first light source is a monochromatic LED light source with a spectral width greater than 10 nanometers and less than 50 nanometers. The diameter of the light transmission hole is less than 0.5 mm, preferably less than 0.2 mm; the distance between the light transmission hole and the first light source is less than 0.5 mm; the focal len...

Embodiment 2

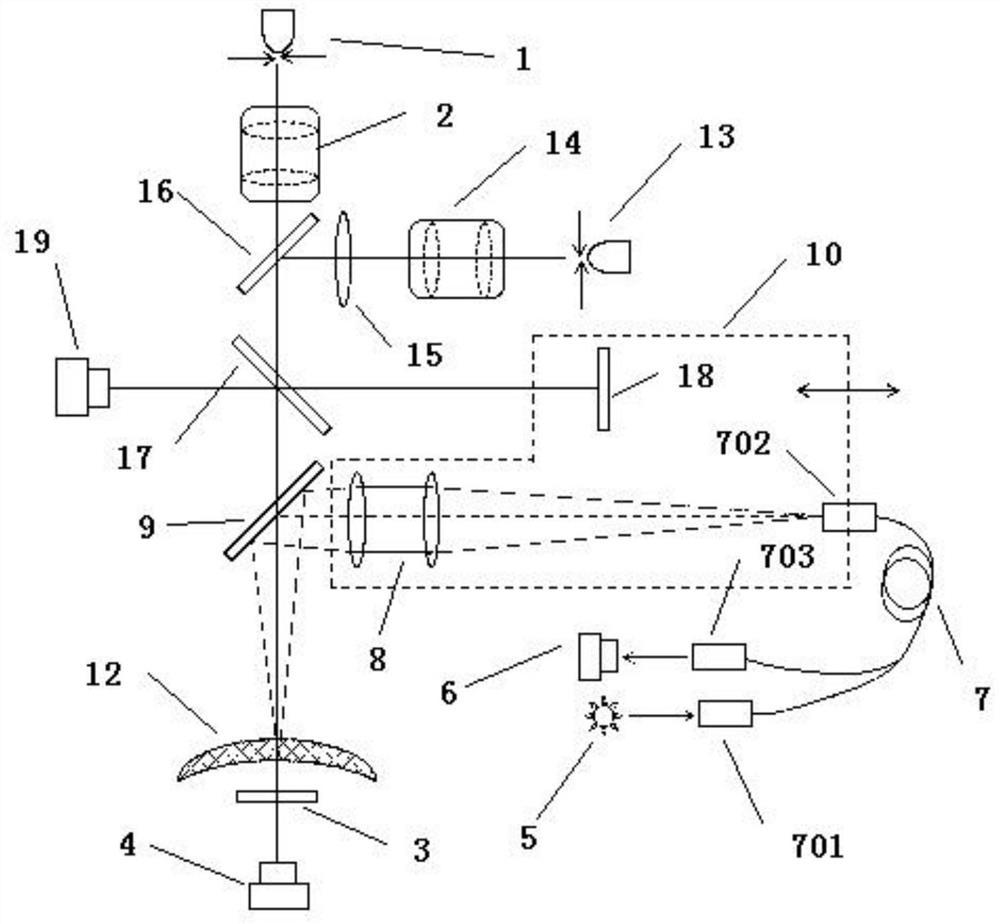

[0044] The lens refraction index measurement device of the present invention includes a diopter measurement module, a confocal reflection measurement module, an optical thickness measurement module and a measured lens.

[0045] The diopter measurement module includes a first light source module 1 , a first collimator lens 2 , a Hartmann diaphragm 3 and a first photodetector 4 . The first light source module 1 includes a first light source and a first hole, and a light-transmitting hole is provided on the side of the first hole near the light-emitting surface of the first light source; The light emitted by the light source is emitted after passing through the light transmission hole. The first light source is a monochromatic LED light source with a spectral width greater than 10 nanometers and less than 50 nanometers. The diameter of the light transmission hole is less than 0.5 mm, preferably less than 0.2 mm; the distance between the light transmission hole and the first ligh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spectral width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com