Method for controlling foaming of desulfurization slurry through front-end co-processing

A desulfurization slurry and control method technology, applied in the field of desulfurization, can solve the problems of difficult to completely cure the foaming of desulfurization absorption tower slurry, not meeting the requirements of civilized production, affecting desulfurization efficiency, etc., so as to avoid the decline of desulfurization efficiency and the abnormal discharge index exceeding the standard. , the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid the understanding of the present invention. It should be pointed out that for those skilled in the art, some modifications can be made to the present invention without departing from the principles of the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

[0031] The present invention proposes a method for controlling the foaming of desulfurization slurry in front-end co-processing. For desulfurization systems of other wet processes, except for limestone-gypsum wet desulfurization, other wet desulfurization towers such as alkali process and ammonia process are also applicable to the present invention.

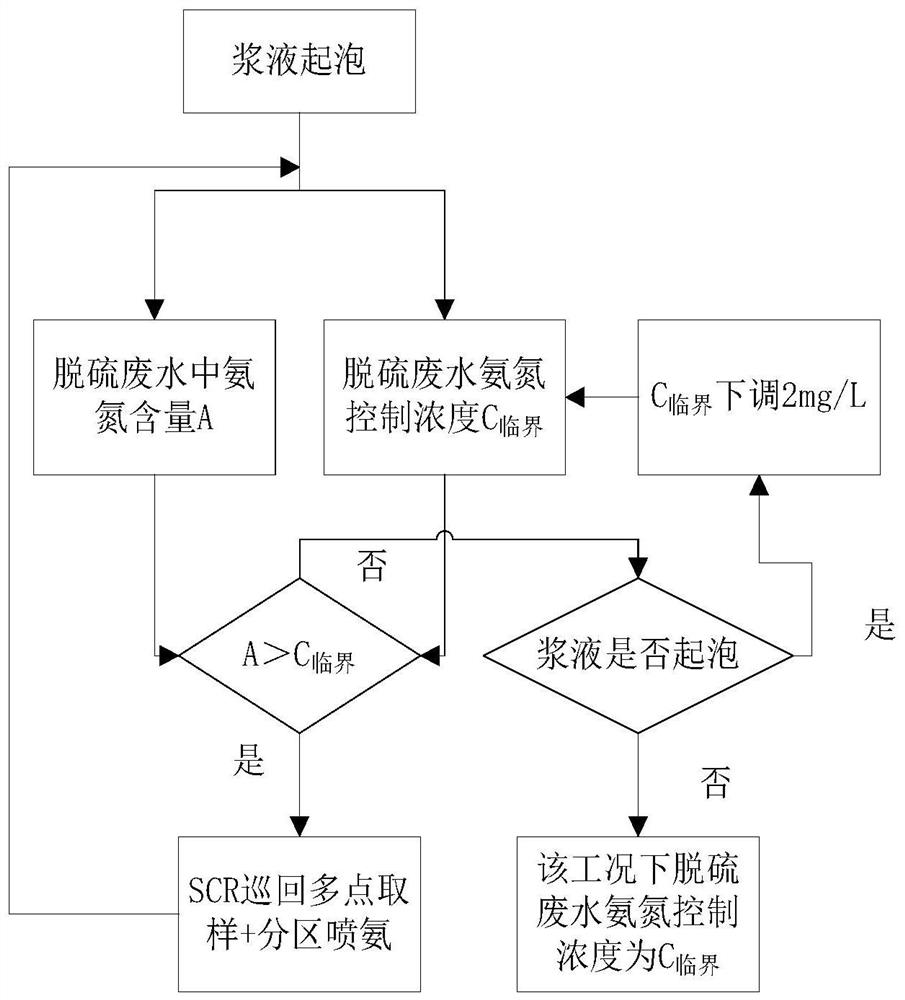

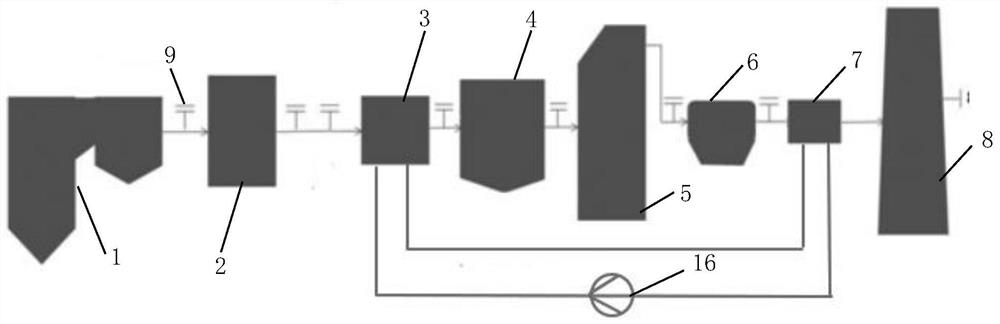

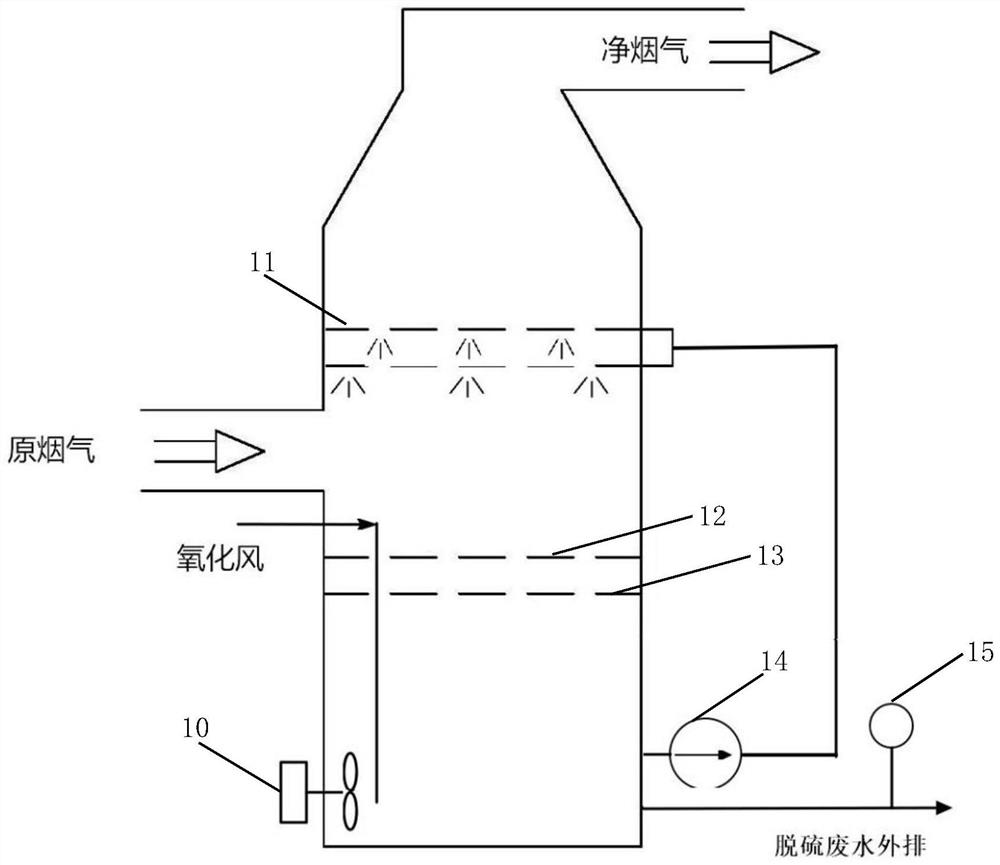

[0032] The main principle of the present invention is: the flue gas is tempered by the main environmental protection equipment in f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com