Gold-polyacid catalyst for color development detection of dopamine and preparation method of catalyst

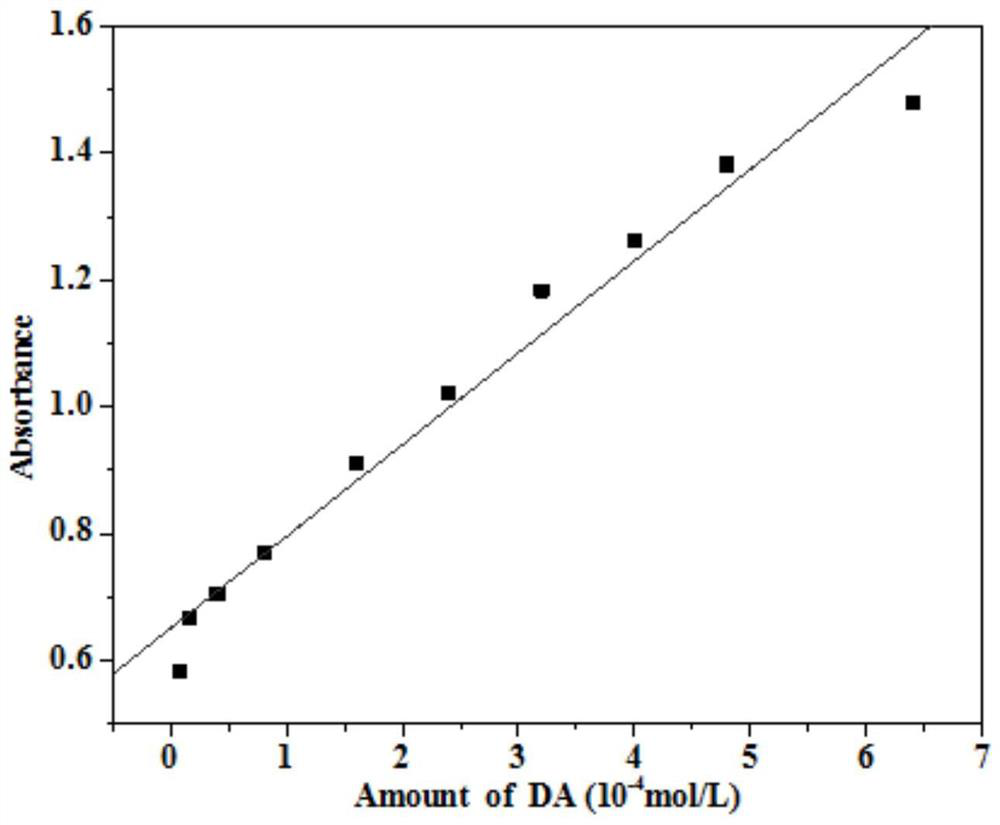

An acid catalyst and dopamine technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of low method and selective application limitations, and achieve accurate color detection, high sensitivity, The effect of high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

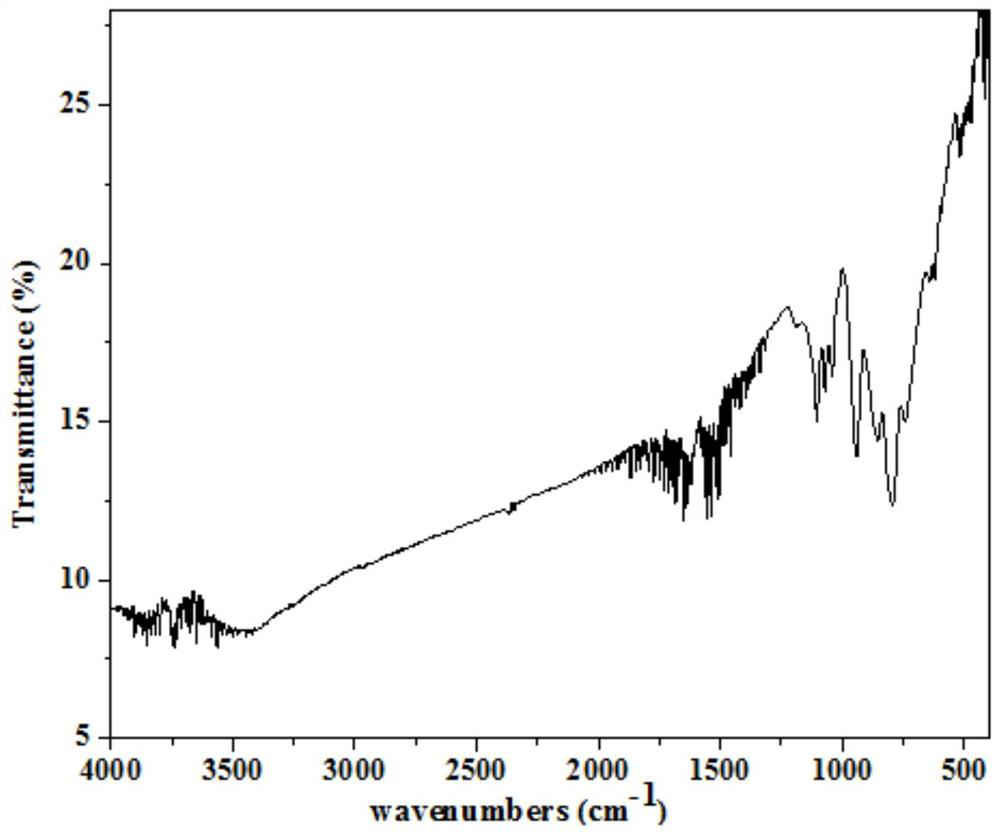

[0025] AU-PW 9 Cu 4 Preparation method

[0026] 3 g of 4 octyl bromide was dissolved in 16 ml of toluene, and 0.153 mmol·L was added to this solution. -1 Haucl 4 After 10 min, 72.4 μl of thiol was added to this solution, stirred at 0 ° C for 10 min, 76 mgnabh 4 The solution was dissolved in 5 ml of deionized water to form a solution, stirred at 0 ° C for 30 min, stirred at room temperature for 3 hours, collecting the organic phase with a rotary evaporator to remove the solvent, dissolved in 50 ml of n-hexane filtered, rotary evaporation and removal solvent, After the addition of 40 ml of ethanol was washed three times, it was dissolved in 15 ml of toluene and 0.01 ~ 0.15 GK 10 [Cu 4 (H 2 O) 2 (PW 9 O 34 ) 2 ] · 20h 2 O (PW 9 Cu 4 The aforementioned solution was dissolved in 10 ml of toluene, and a solution of 1: x (1 to 15) was obtained, and the mixture was stirred at room temperature for 1 hour, and the solvent was rotated at 40 ° C, and then dried in vacuo to give a dark gray po...

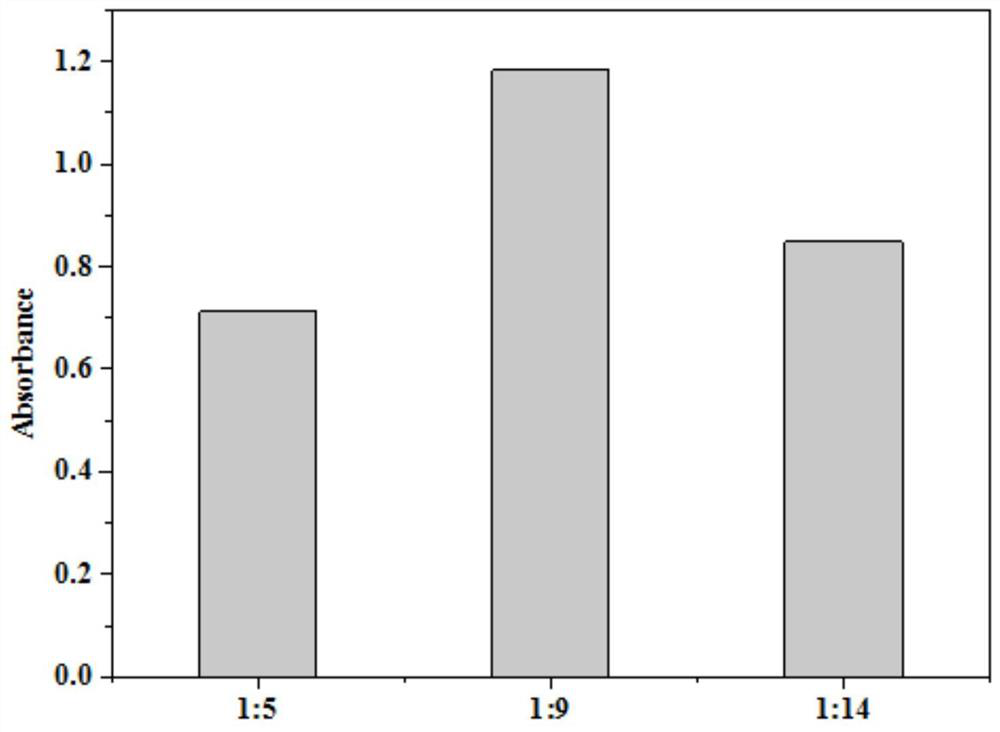

Embodiment 1

[0029] 3 g of 4 octyl bromide was dissolved in 16 ml of toluene, and 0.153 mmol·L was added to this solution. -1 Haucl 4 After 10 min, 72.4 μl of thiol was added to this solution, stirred at 0 ° C for 10 min, 76 mgnabh 4 The solution was dissolved in 5 ml of deionized water to form a solution, stirred at 0 ° C for 30 min, stirred at room temperature for 3 hours, collecting the organic phase with a rotary evaporator to remove the solvent, dissolved in 50 ml of n-hexane filtered, rotary evaporation and removal solvent, After adding 40 ml of ethanol, then dissolved in 15 ml of toluene, 0.05 GK 10 [Cu 4 (H 2 O) 2 (PW 9 O 34 ) 2 ] · 20h 2 O (PW 9 Cu 4 The aforementioned solution was dissolved in 10 ml of toluene to obtain a solution of 1: 5 ratio of solution, and the mixture was stirred at room temperature for 1 hour, and the solvent was rotated at 40 ° C. After the vacuum dried, it was calcined at 300 ° C to obtain dark gray powder, that is, Au-Pw 9 Cu 4 (1: 5) Selective color catalys...

Embodiment 2

[0032] 3 g of 4 octyl bromide was dissolved in 16 ml of toluene, and 0.153 mmol·L was added to this solution. -1 Haucl 4 After 10 min, 72.4 μl of thiol was added to this solution, stirred at 0 ° C for 10 min, 76 mgnabh 4 The solution was dissolved in 5 ml of deionized water to form a solution, stirred at 0 ° C for 30 min, stirred at room temperature for 3 hours, collecting the organic phase with a rotary evaporator to remove the solvent, dissolved in 50 ml of n-hexane filtered, rotary evaporation and removal solvent, After adding 40 ml of ethanol, then dissolved in 15 ml of toluene, 0.09 GK 10 [Cu 4(H 2 O) 2 (PW 9 O 34 ) 2 ] · 20h 2 O (PW 9 Cu 4 The aforementioned solution was dissolved in 10 ml of toluene to give a solution of 1: 9 ratio of solution. After stirring at room temperature for 1 hour, 40 ° C was evaporated to remove the solvent. After vacuum dried, it was calcined at 300 ° C to obtain dark gray powder, that is, Au-Pw 9 Cu 4 (1: 9) Selective test detection of polyacid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com