Integral spinning hemispherical shell dot-matrix type flexible fixing and supporting device

A fixed support and flexible support technology, which is applied in the field of precision machining of hemispherical shell profiles by integral spinning, can solve the problems of lack of support force, inability to solve the fixed support requirements for product processing, and inability to meet the fixed support requirements for product processing, etc. To ensure the machining accuracy, improve the efficiency and reliability of the internal molding machine for the overall spinning hemispherical shell product, and achieve the effect of fast and efficient product fixing and clamping process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

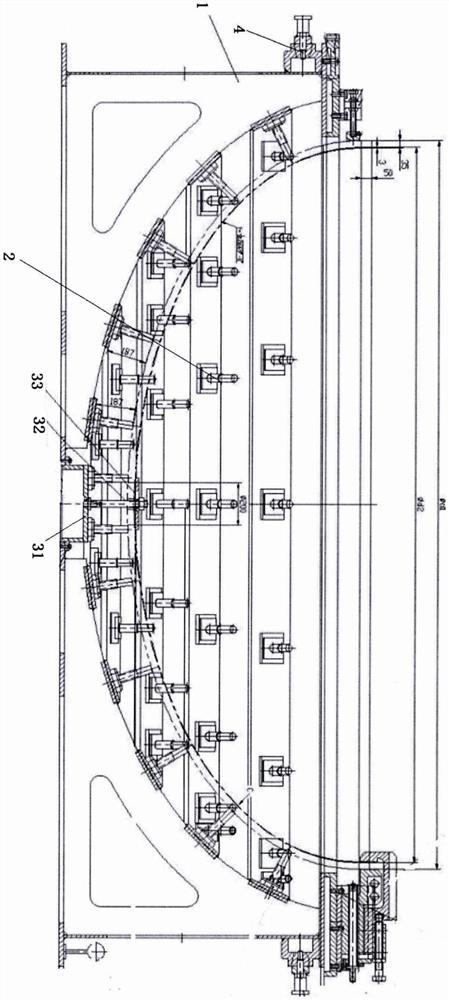

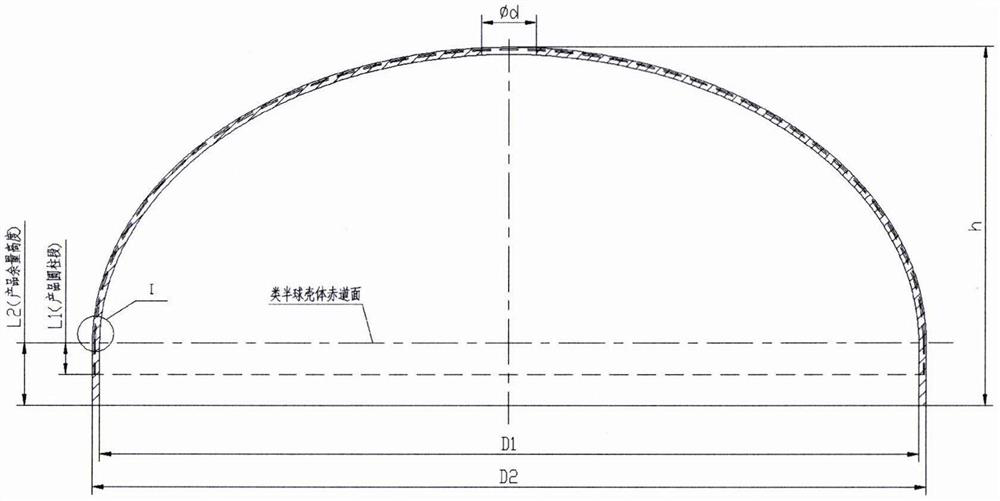

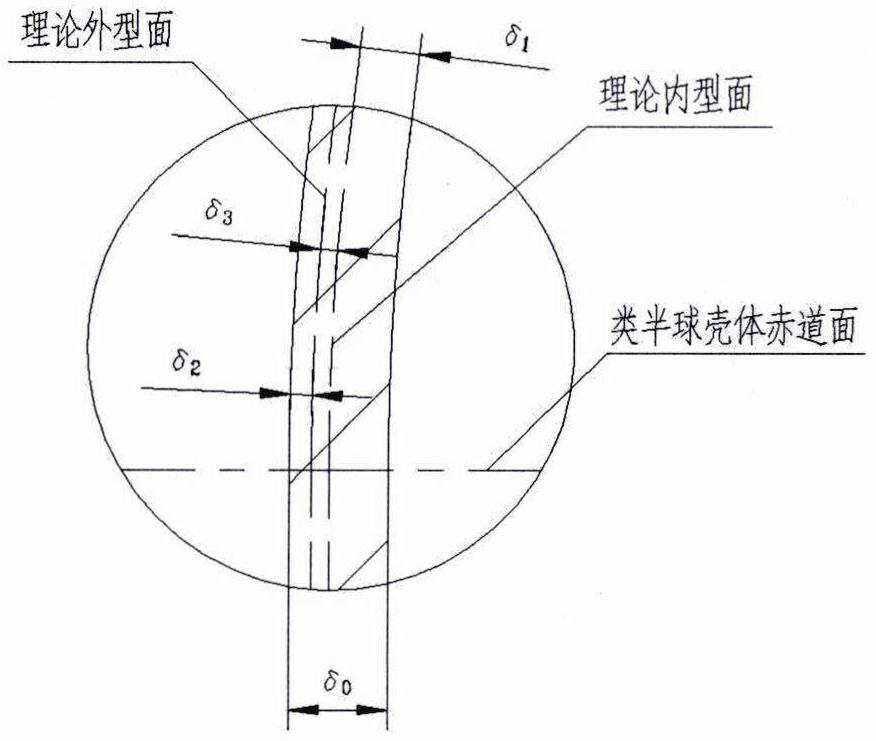

[0031] refer to Figure 4 to Figure 7 The dot-matrix flexible fixed support device for an integral spinning hemispherical shell includes a tooling base 1 and a dot-matrix flexible support mechanism 2. The tooling base 1 is composed of an upper plate 11 on the base, a lower plate 12 on the base, Several base templates 13 and several connecting rings 14 are formed. All the connecting rings 14 are arranged horizontally and are erected between the upper plate 11 of the base and the lower plate 12 of the base through the base templates 13. All the connecting rings 14 start from the top And the bottom is arranged at intervals, all the connecting rings 14 are circular structure and the radius decreases successively from top to bottom, the dot matrix flexible support mechanism 2 includes several flexible supporting assembli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com